Roller press for calcium aluminate powder raw material

A technology of calcium aluminate powder and roller press, which is applied in the preparation of calcium aluminate, alkaline earth metal aluminate/aluminum oxide/aluminum hydroxide, grain processing, etc., and can solve the problems of high temperature and easy wear of the roller surface, Achieve the effect of reducing the wear rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

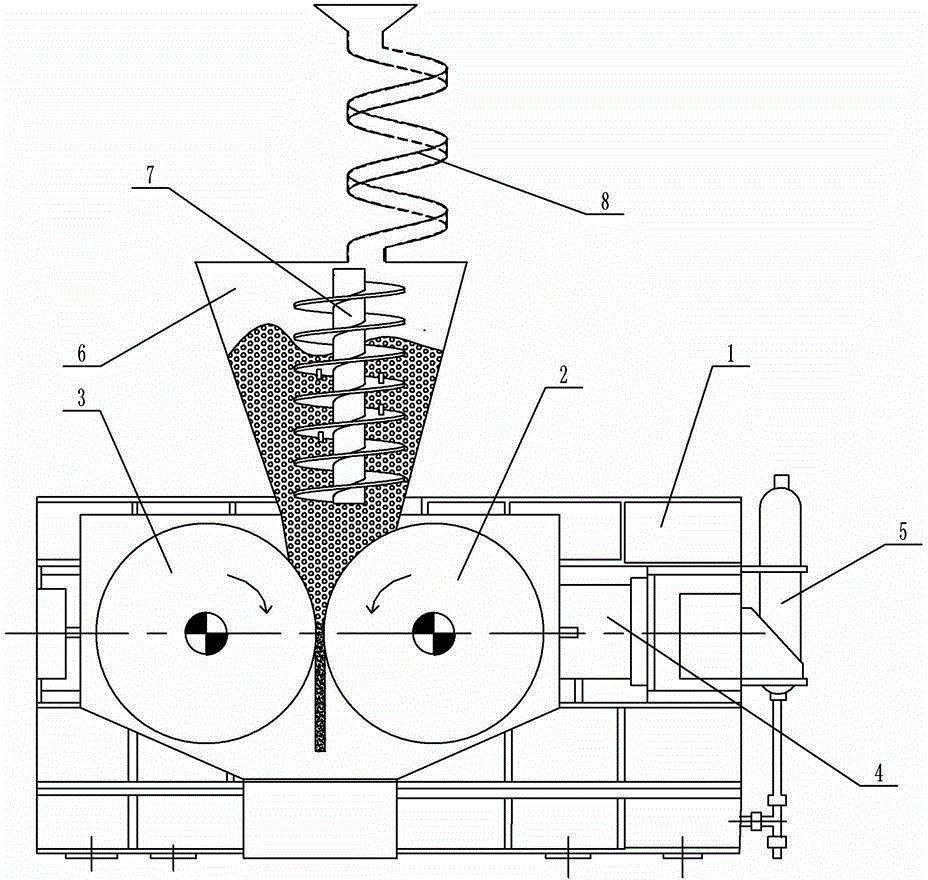

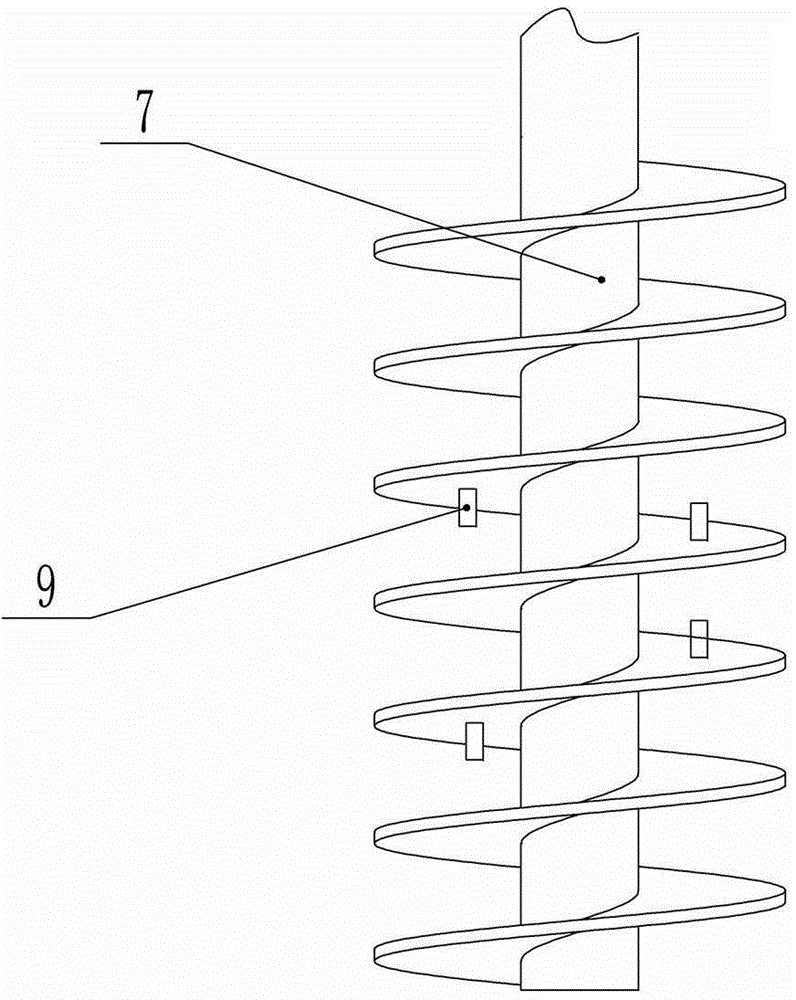

[0017] The reference signs in the description of the drawings are: frame 1, driving roller 2, driven roller 3, hydraulic cylinder 4, nitrogen bag 5, feeding device 6, spiral reamer 7, spiral channel 8, stopper 9.

[0018] like figure 1 As shown, this embodiment provides a rolling machine for calcium aluminate powder raw materials, including a frame 1, a driving roller 2, a driven roller 3, a driving motor, a hydraulic device 4 and a feeding device 6. The feeding device 6 is conical and fixed on the frame 1. The feeding device 6 is welded with a spiral passage 8, and a funnel-shaped feed opening is provided above the spiral passage 8. Raw materials enter the spiral channel 8 through the funnel-shaped feeding port, and enter the feeding device after preliminary mixing. like figure 2 As shown, the feeding device 6 is provided with a motor and a spiral reamer 7, and a plurality of stoppers 9 are welded on the spiral reamer 7. The feeding device 6 stirs the raw materials to mak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com