Effect enhancing method of compound biobased fertilizer and fertilizer with enhanced effect

A bio-based, compound fertilizer technology, applied in fertilizer mixtures, bio-organic part treatment, organic fertilizers, etc., can solve problems such as environmental risks and expensive chemical-based materials, improve crop quality, control loss, and improve the ecological environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] In order to further explain the preparation method of the fertilizer efficiency-enhancing factor, the present invention further makes a more detailed example.

[0045] Scrape a ring of bacteria from the preservation slope of CSF-1 strain and inoculate it into a 300ml Erlenmeyer flask containing 20ml seed medium. Incubate for 14 hours at 37° C. on a shaker with a rotation speed of 200 rpm. Then inoculate it into a 1000ml Erlenmeyer flask containing 150ml of fermentation medium at a ratio of 1:100 and cultivate it for 12-16 hours to make a bacterial suspension (solid-state fermentation seed solution) for later use.

[0046] Composition of seed medium and fermentation medium (based on 1000mL medium): maltose 40g, soluble starch 40g, glutamic acid 20g, MgSO 4 0.5g, KCl 0.5g, KH 2 PO 4 1g, FeSO 4 ·7H 2 O0.15g, MnSO 4 0.005g, CuSO 4 ·5H 2 O 0.00016g, yeast extract 1g, pH 7.0-7.2. The above-mentioned culture medium was at 1.0×10 5 Pa, sterilize at 121°C for 20 min...

Embodiment 1

[0054] There is a white or light brown film on the surface of the downstream substrate after solid fermentation, thicker mucus can be seen and filaments can be drawn out when stirred with a needle, suggesting that a high molecular weight polymer similar to γ-polyglutamic acid has been synthesized by fermentation. Detecting its productive rate is 40-60g / kg (material), molecular weight is between 40-150kDa.

[0055] The fermentation substrate was dried, weighed 0.1 g, and extracted with 4 ml of pure water (2.5% concentration). After the insoluble particles were precipitated, the supernatant (leaching solution) was taken, and the concentration of the supernatant was 0.87%. The supernatant was tested for flocculation of soil colloids.

[0056] Prepare 2.5% polyaluminum chloride solution as a control, and compare the flocculation effect of the two on soil colloid.

[0057] The soil was dried and pulverized, and 0.4 g was weighed and added to 40 ml of pure water to make a suspensio...

Embodiment 2

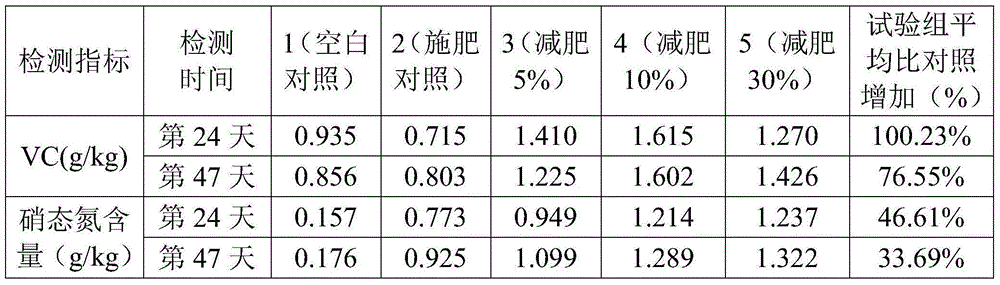

[0063] To prepare the efficiency-enhancing factor of 1 kg of composite bio-based efficiency-enhancing urea, the weight ratio of soybean meal-corn germ meal-attapulgite in the solid fermentation medium used is 60-20-20.

[0064] Take 6 acrylic tubes with a length of 490 mm and an inner diameter of 14 mm. Tubes No. 1, 2 and 3 are used as the control group, and tubes No. 4, 5 and 6 are used as the experimental group. 45g of 80-100 mesh quartz sand (height about 200mm) was filled in the 6 tubes first, the control group was filled with a mixture of 0.1g urea and 1g quartz sand, and finally covered with 10g quartz sand; while the experimental group was filled with 0.1g urea and 0.01g efficiency-enhancing factor Mix with 1g of quartz sand, and finally cover with 10g of quartz sand.

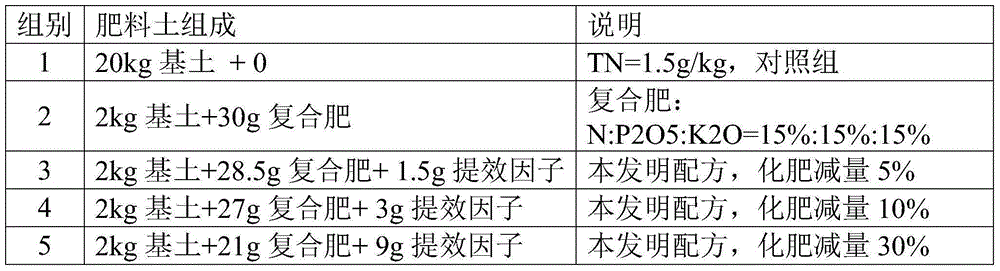

[0065] The 6 tubes are vertically placed on the support, and water is leached from above, and the water feeding rate is 0.1ml / min. Collect once every 30 minutes, collect the filtrate in three time perio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com