A method for remanufacturing the inner wall of sleeve parts by induction cladding

A kind of sleeve and remanufacturing technology, applied in the direction of coating, metal material coating process, etc., can solve the problems of unable to solve the problem of remanufacturing and repairing waste parts, limited film thickness, low deposition efficiency, etc., to achieve energy saving and material saving. Remarkable environmental protection effect, narrow heat-affected zone and low roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The present invention is a method for remanufacturing the inner wall of bushing parts of heavy-duty crawler vehicles by induction cladding. In view of the serious wear of the inner wall parts and the unilateral dimension out-of-tolerance range reaches 05-0.7mm, the technical solution given is:

[0026] (1) Use acetone as the cleaning agent to perform ultrasonic cleaning on the parts to be treated to remove oil and other pollutants on the surface of the inner wall.

[0027] Grinding pretreatment is carried out on the surface of the inner wall by a grinder, and the size of the inner wall is Φ80.75mm.

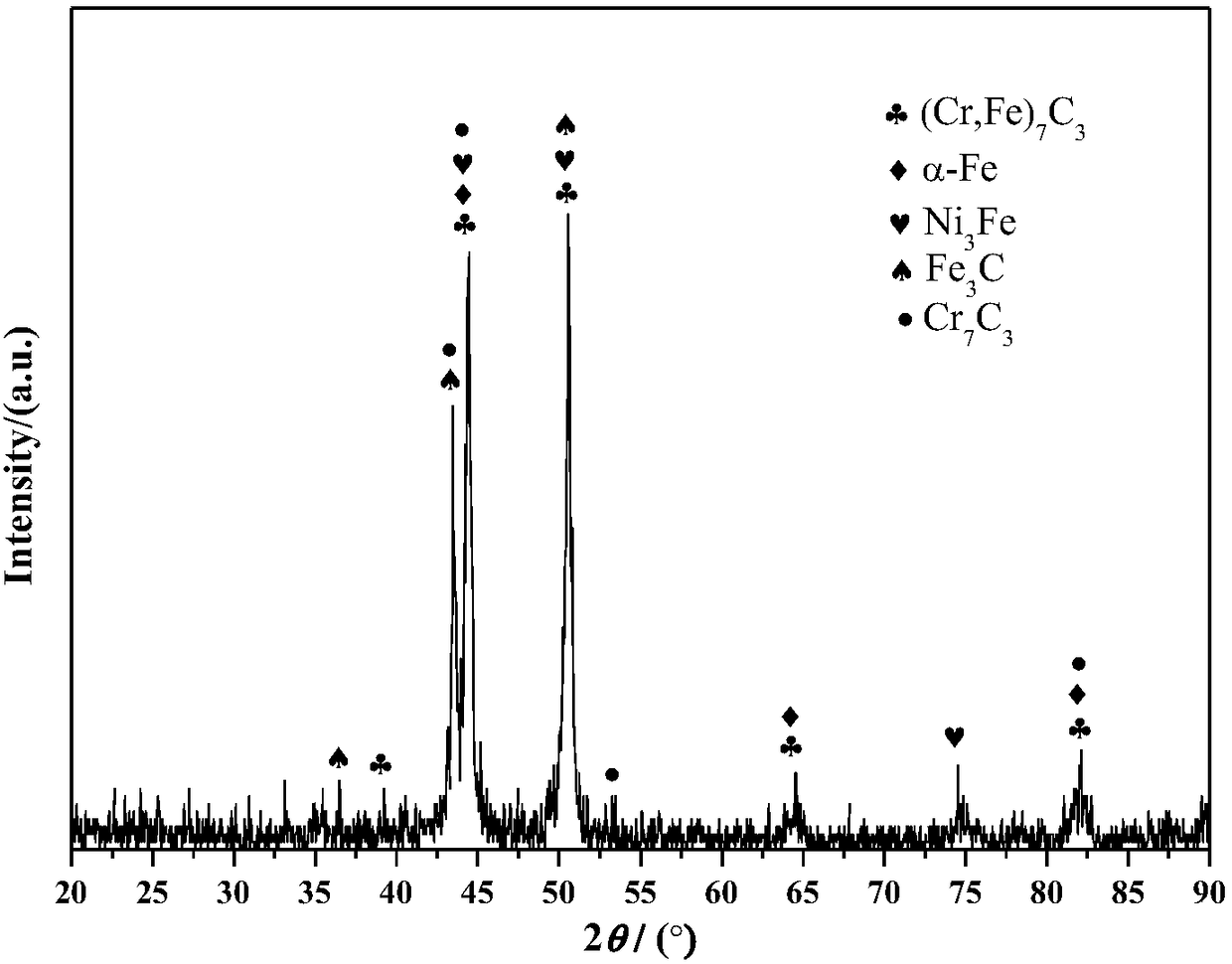

[0028] (2) Mix rosin and turpentine at a mass ratio of 1:3 and heat to 90°C to make a binder. Mix the iron-based alloy powder and the binder according to the mass ratio of 10:1 and stir evenly to make a paste. With the help of a scraper and a clamping rotary tool, evenly apply the prepared paste powder / binder mixture on the surface of the inner wall of the part after step ...

Embodiment 2

[0034] The present invention is a method for remanufacturing the inner wall of bushing parts of heavy-duty crawler vehicles by induction cladding. Aiming at the moderate wear of the inner wall parts, the technical solution given is:

[0035] (1) Use acetone as the cleaning agent to perform ultrasonic cleaning on the parts to be treated to remove oil and other pollutants on the surface of the inner wall.

[0036] Grinding pretreatment is carried out on the surface of the inner wall by a grinder, and the size of the inner wall is obtained to be Φ80.55mm.

[0037] (2) Mix rosin and turpentine at a mass ratio of 1:3 and heat to 90°C to make a binder. Mix the iron-based alloy powder and the binder according to the mass ratio of 10:1 and stir evenly to make a paste. With the help of a scraper and a clamping rotary tool, evenly apply the prepared paste powder / binder mixture on the surface of the inner wall of the part after step (1), with a thickness of about 0.75mm. Put the parts ...

Embodiment 3

[0043] The present invention is a method for remanufacturing the inner wall of sleeve parts of heavy-duty crawler vehicles by induction cladding. Aiming at the mild wear of the inner wall parts, the technical solution given is:

[0044] (1) Use acetone as the cleaning agent to perform ultrasonic cleaning on the parts to be treated to remove oil and other pollutants on the surface of the inner wall.

[0045] Grinding pretreatment is carried out on the surface of the inner wall by a grinder, and the size of the inner wall is obtained to be Φ80.35mm.

[0046] (2) Mix rosin and turpentine at a mass ratio of 1:3 and heat to 90°C to make a binder. Mix the iron-based alloy powder and the binder according to the mass ratio of 10:1 and stir evenly to make a paste. With the help of a scraper and a clamping rotary tool, evenly apply the prepared paste powder / binder mixture on the surface of the inner wall of the part after step (1), with a thickness of about 0.5 mm. Put the parts into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com