Modification treatment method for surface of space material reflector blank

A processing method and reflector technology, which is applied in the direction of testing material hardness, metal material coating process, liquid chemical plating, etc., can solve the problems of difficult high precision and ultra-smooth surface of reflector blanks, and achieve strong process realizability , loading ratio limit is small, the effect of stable deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

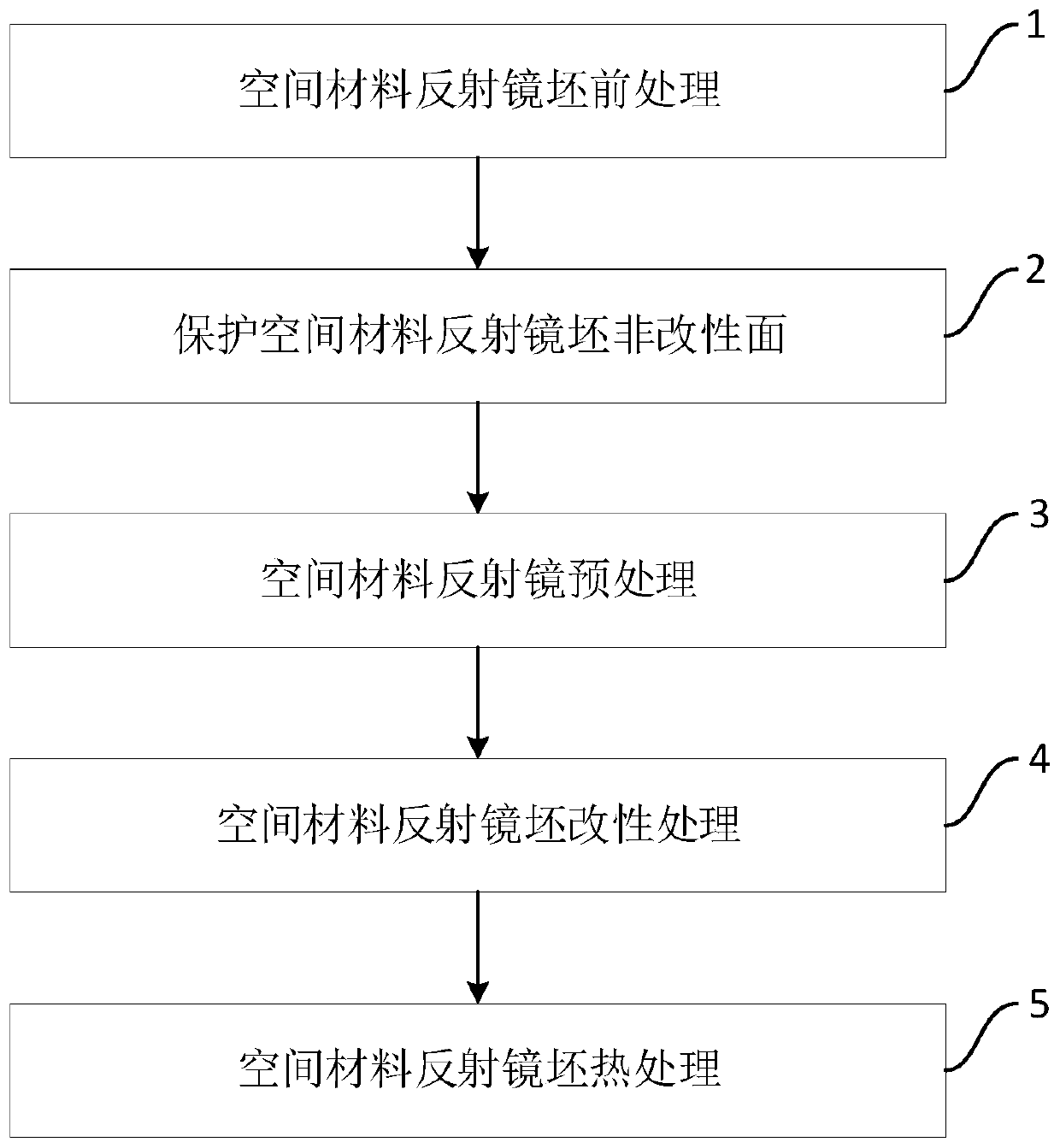

Method used

Image

Examples

Embodiment 1

[0066] Embodiment 1: Surface modification treatment of LD5 mirror blank

[0067] 1) Chemical degreasing of the mirror blank: according to the ratio of 20g / L of hydroxide, 15g / L of sodium silicate, 20g / L of sodium carbonate, and 15g / L of sodium phosphate, add the above-mentioned medicines into deionized water, mix evenly, and obtain chemical Degreasing solution, working temperature is 60°C. Immerse the LD5 reflector blank in the chemical degreasing solution, take it out after 15 minutes of degreasing, and observe whether a continuous water film is formed on the surface of the mirror blank after cleaning with deionized water, if not, continue to immerse in the chemical degreasing solution to remove oil until A uniform and continuous water film is formed on the surface of the mirror blank.

[0068] 2) Treatment for protecting the non-modified surface: coating the non-modified surface of the LD5 mirror blank after chemical degreasing with peelable protective glue.

[0069] 3) Mo...

Embodiment 2

[0073] Example 2: Surface modification treatment of Al-SiC mirror blank

[0074] The difference between embodiment 2 and embodiment 1 is that the proportioning of modification treatment solution is different, and embodiment 2 is by nickel sulfate 40g / L, sodium hypophosphite 20g / L, sodium citrate 20g / L, sodium acetate 15g / L, The ratio of lead sulfate 0.8mg / L is prepared, and the pH value of the modification treatment solution is adjusted to 5 with acetic acid, and the temperature of the modification treatment solution is controlled at 93°C. Dip the mirror base dipped in the aluminum and aluminum alloy zinc immersion solution in the modification treatment solution, react for 20 hours, and complete the preparation of the modification layer.

[0075] The thickness of the nickel-phosphorus alloy modified layer obtained in Example 2 of the present invention was measured by a microhardness meter to be 115 μm, the microhardness was 541 Hv, and the phosphorus content was 10.5%. After t...

Embodiment 3

[0076] Embodiment 3: Surface modification treatment of Al (7A09) mirror blank

[0077] The difference between Example 3 and Example 1 is that the proportions of the modified pretreatment solution and the modified treatment solution are different.

[0078] Embodiment 3 According to the ratio of sodium hydroxide 400g / L, zinc oxide 20g / L, cuprous cyanide accelerator 15g / L, above-mentioned medicine is added in deionized water, mix uniformly, obtain aluminum and aluminum alloy zinc dipping solution, put Al(7A09) mirror blank is immersed in aluminum and aluminum alloy zinc dipping solution for 40 seconds.

[0079] The modified layer solution was prepared according to the ratio of nickel sulfate 30 / L, sodium hypophosphite 10g / L, sodium citrate 15g / L, sodium acetate 10g / L, lead sulfate 0.5mg / L, and the modified layer was mixed with acetic acid The pH value of the solution was adjusted to 5, and the temperature of the modified layer solution was controlled to be 92°C. Dip the mirror ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com