High abrasion-proof steel piston ring and its production technique

A piston ring, high wear-resistant technology, applied in the field of piston rings, can solve the problem of no soft coating, etc., and achieve the effects of good wear resistance, high film-base bonding force, and controllable microhardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

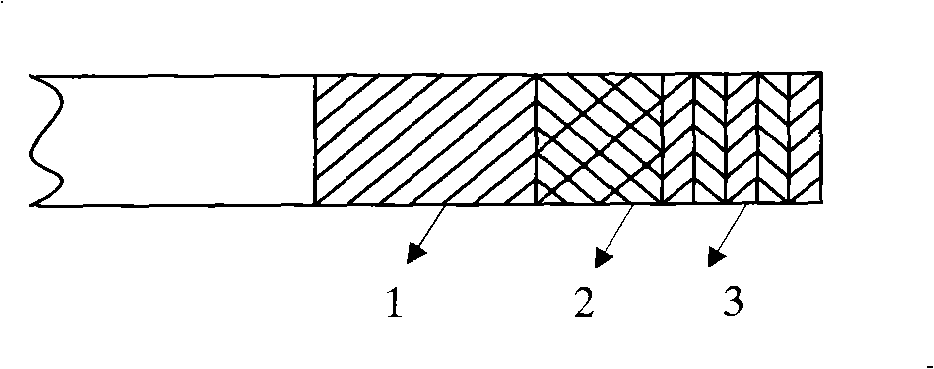

[0018] Further illustrate the present invention in conjunction with accompanying drawing and embodiment, as figure 1 As shown, the present invention uses gas nitriding to form a pretreatment layer 2 on the surface of a steel substrate 1, and then coats a wear-resistant layer formed by a multi-element nanofilm of chromium nitride and titanium nitride in a multi-arc ion plating equipment 3. The wear-resistant layer 3 is formed by stacking chromium nitride and titanium nitride. The thickness of the layered film is 200-500nm, the hardness is 2000-2600HV, and the total thickness is 6μm, which is better than the steel ring with only the nitride layer. Can be increased by 3 times. The first layer or the outermost layer of the multiple multi-layer nano-film wear-resistant layer 3 is coated with a chromium nitride layer. The pretreatment layer is a nitride layer, or a pure titanium layer, or a chromium nitride layer.

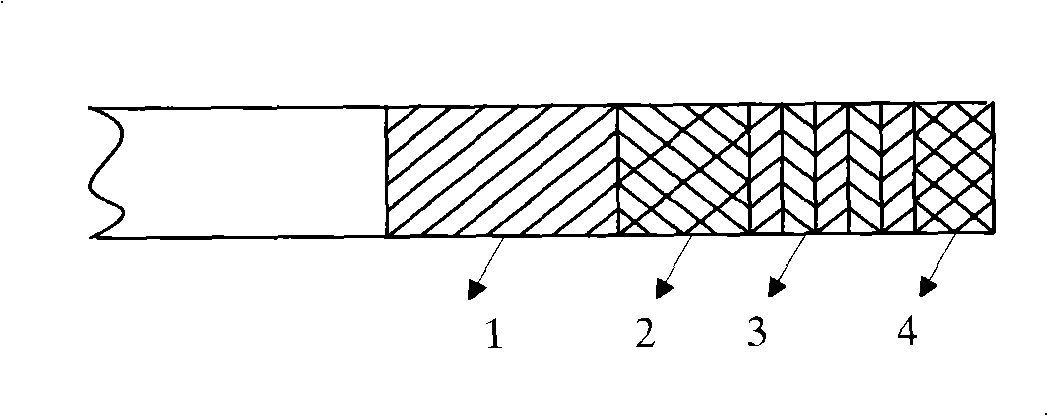

[0019] Such as figure 2 As shown, on the surface of the stainl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com