A needle-free electrospinning device for porous materials

A porous material, electrospinning technology, used in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of difficult control of spinning diameter, spinning sticking, etc. The effect of uniform yarn and improved spinning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

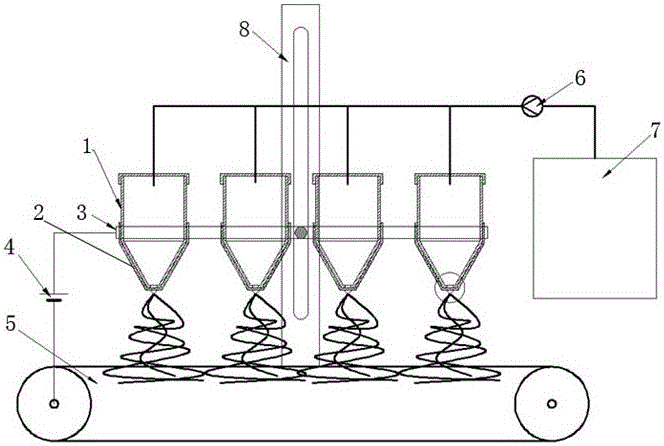

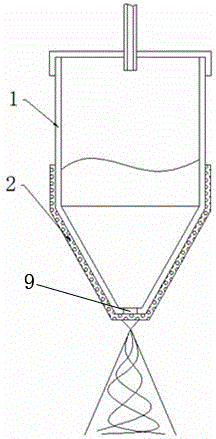

[0025] Mix and stir polyacrylonitrile (PAN), N,N dimethylformamide (NMP) and ethanol to form an 8wt% PAN solution; then add acetylacetone, stir evenly, add a certain amount of nano-silica powder and continue stirring until form a suspension, such as Figure 7 As shown, a porous copper foil with a pore size of 75 μm and a porosity of 45% is used as the porous medium 2, and it is matched with a 20ml spinning buffer tube 1, and the opening of the bottom end of the spinning buffer tube 1 is 8 mm, such as figure 2 As shown, wrap the porous medium 2 on the liquid outlet hole 9 at the bottom of the spinning buffer tube 1, install the spinning buffer tube 1 on the fixed copper core fixture 3, and wrap the porous medium on the spinning buffer tube 1 2. Closely contact with the inner surface of the 3 holes of the fixed copper core fixture to play the role of conducting voltage, and set the distance between spinning heads to 15cm. Such as figure 1 As shown, the solution is injected in...

Embodiment 2

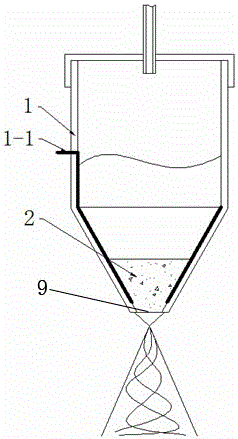

[0027] Configure 50wt% PVDF acetone solvent, add 2wt% water and mix to form spinning slurry. The size of the liquid outlet at the bottom is selected as a 20mm buffer cylinder, and the volume of the buffer cylinder is 200ml; powder metallurgy porous nickel is selected as the porous medium 2, with a porosity of 60%, a pore diameter of 100μm, and a thickness of 6mm. Such as image 3 As shown in the figure, when assembling, the copper conical electrode 1-1 is first inserted into the bottom of the spinning buffer tube 1, and the top end passes through the wall of the spinning buffer tube 1. Such as Figure 4As shown, the shape of the conical electrode 1-1 is the same as the shape of the bottom end of the spinning buffer tube 1, and plays the role of connecting the spinning solution in the spinning buffer tube 1 with the outer fixture. Afterwards, the porous medium 2 is cut into the same shape as the bottom of the spinning buffer cylinder 1, and placed into the liquid outlet hole ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com