Silver alloy sputtering target for forming electroconductive film, and method for manufacturing same

A technology of conductive film and manufacturing method, which is applied in the manufacture of semiconductor/solid-state devices, sputtering coating, circuits, etc., can solve the problems of increased sputtering and arc discharge times, and achieve the purpose of suppressing arc discharge, suppressing sputtering, Excellent durability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

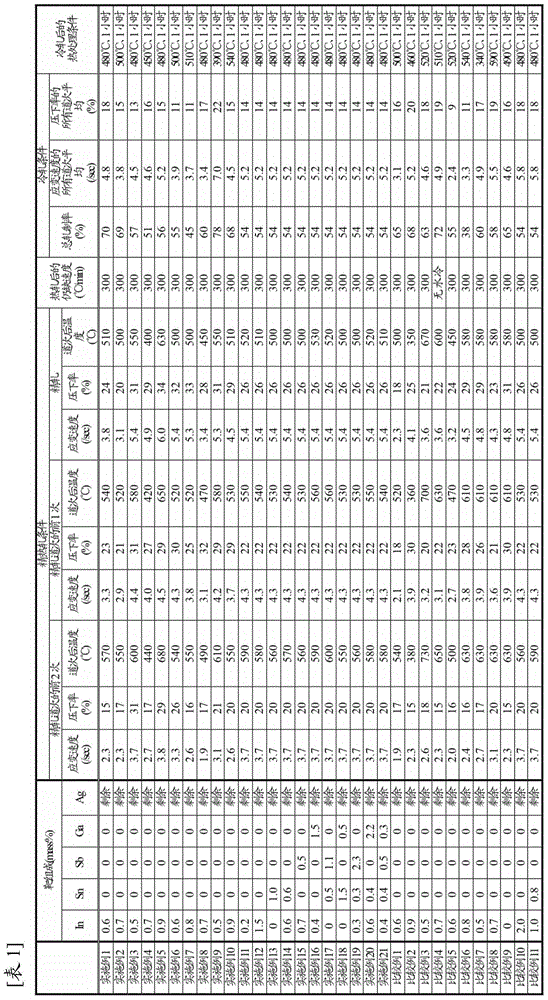

[0085] Ag with a purity of 99.99% by mass or more and In, Sn, Sb, and Ga with a purity of 99.9% by mass or more as additive raw materials were prepared and charged in a high-frequency induction melting furnace built with a graphite crucible. The total mass at the time of melting was set at about 1100 kg.

[0086] When smelting, Ag is smelted first, and after Ag is melted, raw materials are added so as to obtain the target composition shown in Table 1, and the alloy molten metal is sufficiently stirred by the stirring effect by induction heating, and cast iron mold For casting.

[0087] The shrinkage cavity portion of the ingot obtained by this casting was cut off, and the surface in contact with the mold was removed by face cutting to obtain a cuboid ingot with an approximate size of 640×640×180 (mm) as a complete part.

[0088] This ingot was heated to 650° C., the rolling direction was changed on the way, and hot rolling was repeated several times until the plate thickness ...

Embodiment 2~21

[0093] (Examples 2-21, Comparative Examples 1-11)

[0094] Same as Example 1, with the target composition shown in Table 1, the conditions of the passes from the last hot rolling pass to the first two passes in the finish hot rolling (rolling rate of each pass, strain rate, pass after pass) plate temperature), cooling rate after hot rolling, cold rolling conditions (total rolling rate of cold rolling, average value of all cold rolling passes of rolling rate of each pass, all cold rolling passes of strain rate The mean value in), and the conditions of heat treatment conditions (temperature, time) after cold rolling are carried out smelting, casting, hot rolling, cooling, cold rolling, after heat treatment, make embodiment 2~21 by rectification, machining, Targets of Comparative Examples 1-11. The cooling rates described in Table 1 are cooling by water spraying, and non-water cooling is cooling by only standing cooling.

[0095]

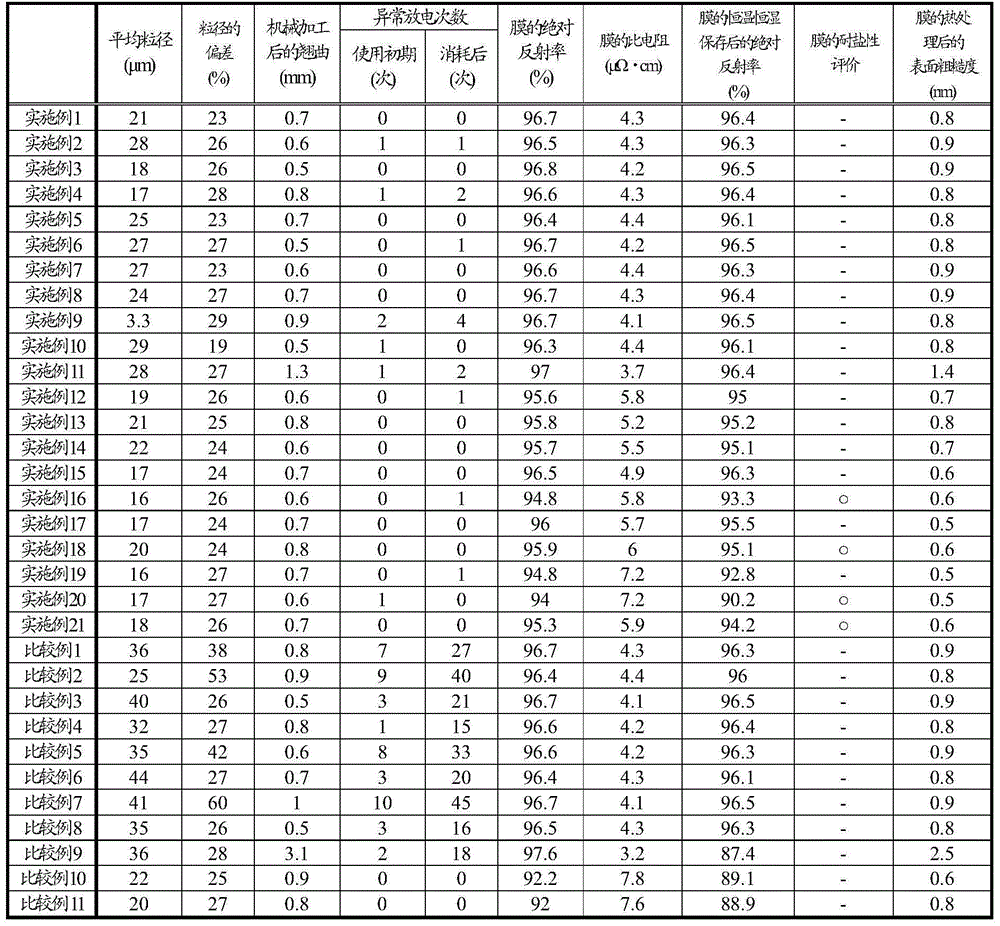

[0096] For the obtained target, the warpage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com