Mg discontinuous insertion layer for improving mt j shunt

A technology of magnetic tunnel junction components and insertion layers, which is applied in the fields of magnetic field controlled resistors, components of electromagnetic equipment, manufacturing/processing of electromagnetic devices, etc., which can solve the problem of increased short circuit phenomenon, loss of current path, and inability to produce wear and tear magnetoresistance etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

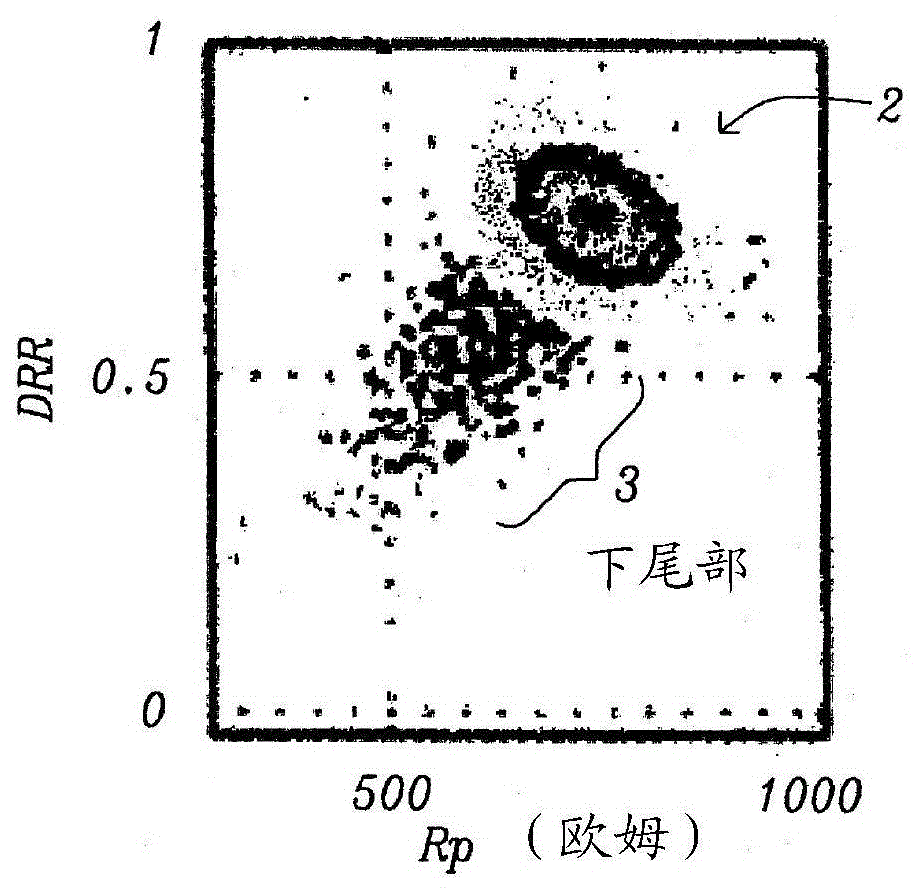

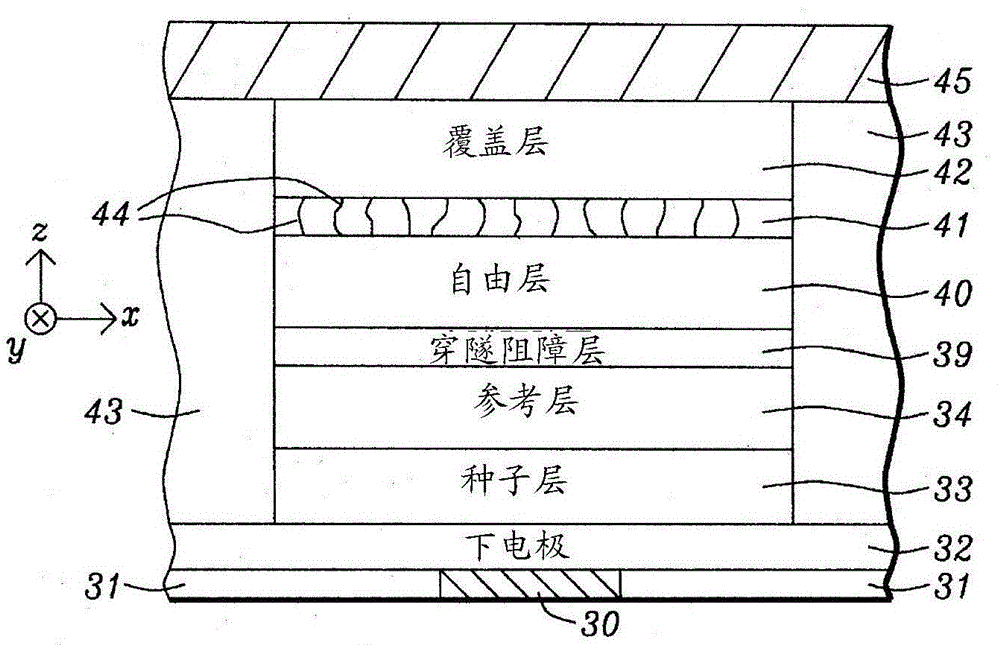

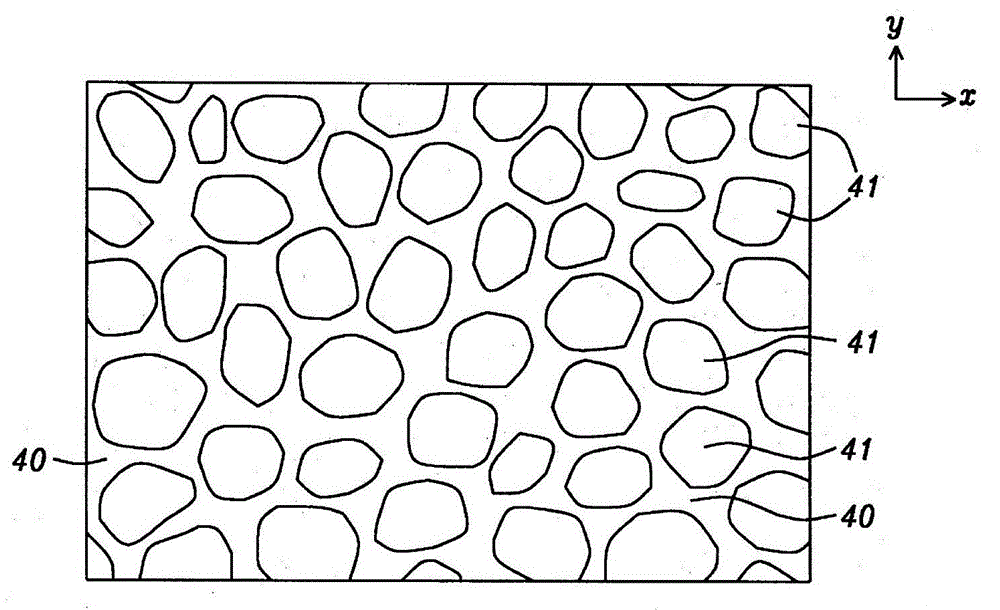

[0023] The invention discloses a magnetic tunnel junction (MTJ) structure, which is used for magnetic sensors, spin transfer torque random access memory (spin transfer torque random access memory, hereinafter referred to as STT-RAM) or other spintronic devices (spintronic devices) ), which can reduce the occurrence of short circuits while maintaining its characteristics, such as high tunneling magnetoresistance ratio (dR / R), low specific junction resistance and area (RA), and low critical current density. The necessary conditions to improve the performance of high-density STT-RAM. The contents of the drawings are only used to illustrate an example of the present invention, and are not intended to limit the protection scope of the present invention. In one embodiment, the present invention shows a single magnetic tunnel junction element instead of a traditional magnetoresistive random access memory (Magnetoresistive Random Access Memory (MRAM) has multiple magnetic tunnel junct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com