Degradable three-dimensional porous magnesium-based biomaterial and preparation method thereof

A three-dimensional porous, biological material technology, used in prosthesis, medical science and other directions, can solve the problems of corrosion of pore-forming agent magnesium matrix metal, can not guarantee the uniformity of pore shape and pore structure connectivity performance, etc. Beneficial for nutrient exchange and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

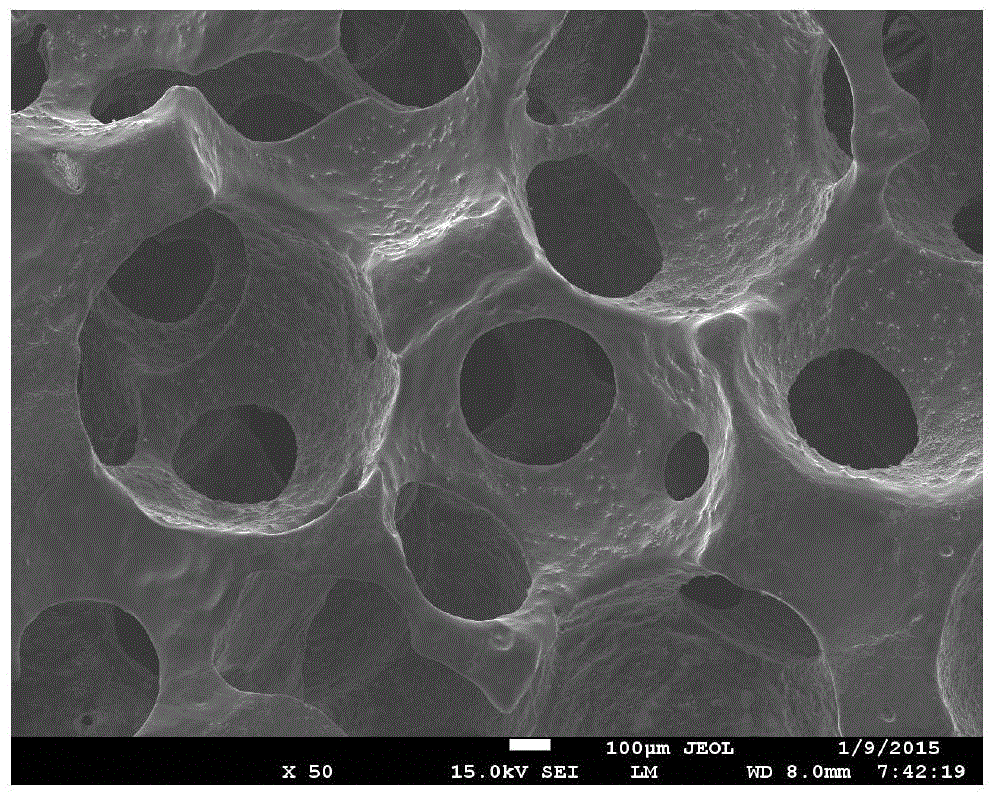

[0022] This embodiment relates to a degradable three-dimensional open-pore porous magnesium alloy used in the field of tissue engineering. The pore type is spherical and the pore diameter is 400-600 μm. It is 150-250 μm, and the porosity is 75%. Its structure is as figure 1 As shown in the physical figure, it can be seen that the spherical hole type and the connected holes evenly distributed on the hole wall.

[0023] This embodiment relates to the aforementioned degradable three-dimensional open-pore porous magnesium and magnesium alloy preparation method for tissue engineering, and the method includes the following steps:

[0024] Step 1, conduct spark plasma sintering of spherical titanium particles with a size of 400-600 μm, the sintering temperature is 800°C, the heating rate is 20°C / min, the pressure is 5MPa, heat preservation and pressure holding for 3 minutes, and then naturally cool to obtain an open porous titanium ball preform ;

[0025] Step 2: Fill the Mg-5wt.%...

Embodiment 2

[0028] This embodiment relates to a degradable open-pore porous magnesium alloy used for bone tissue engineering scaffolds. The pore type is spherical and the pore diameter is 400-600 μm. It is 250-350 μm, and the porosity is 85%.

[0029] This embodiment relates to the aforementioned degradable open-pore porous magnesium and magnesium alloy preparation method for tissue engineering scaffolds, the method includes the following steps:

[0030] Step 1, conduct discharge plasma sintering of spherical iron particles with a size of 400-600 μm, the sintering temperature is 900°C, the heating rate is 40°C / min, the pressure is 10MPa, heat preservation and pressure holding for 3 minutes, and then naturally cool to obtain a perforated porous iron ball prefabricated body ;

[0031] Step 2: Fill the Mg-3wt.%Nd-0.2wt.%Zn-0.5wt.%Zr-0.5wt.%Ca alloy into the gap of the porous iron ball preform by infiltration casting at 720°C and a pressure of 6MPa , and air-cooled to room temperature to ob...

Embodiment 3

[0034] This embodiment relates to a degradable open-pore porous magnesium alloy used for tissue engineering scaffolds. The pore type is spherical and the pore diameter is 800-1000 μm. ~500μm, the porosity is 90%.

[0035] This embodiment relates to the aforementioned degradable three-dimensional open-pore porous pure magnesium preparation method for tissue engineering scaffolds, and the method includes the following steps:

[0036] Step 1, hot isostatic pressing sintering of spherical titanium particles with a size of 600-800 μm, the sintering temperature is 1000°C, the heating rate is 100°C / min, the pressure is 50MPa, heat preservation and pressure holding for 5 minutes, then naturally cool to obtain open porous iron balls Preform;

[0037] Step 2: Fill the pure magnesium melt into the gap of the porous iron ball preform by percolation casting at 720°C and a pressure of 0.1 MPa, and air-cool to room temperature to obtain a composite block of the preform and pure magnesium

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com