Laser welding device carrying multiple sensors

A laser welding and sensor technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of changing the focus position caused by different positions in the optical path, affecting the stability of the focus position, etc., achieving maximum flexibility, Save manpower and material resources, high power density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

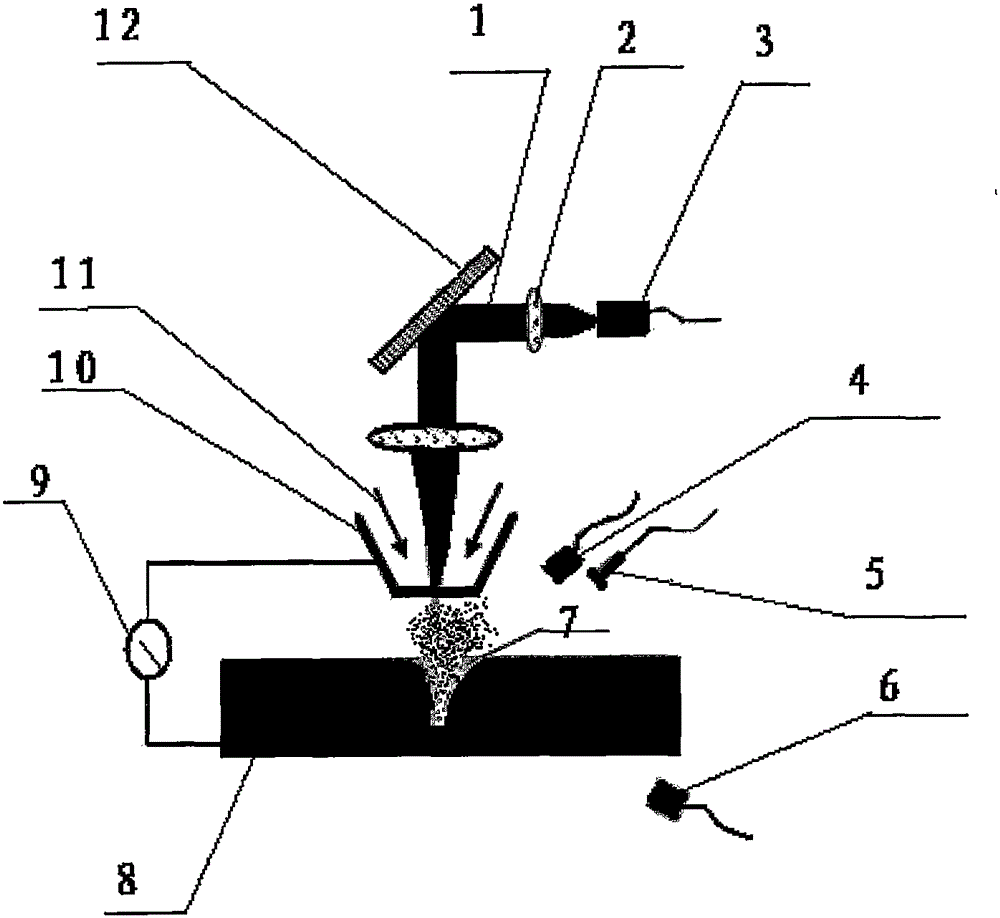

[0021] Such as figure 1 As shown, the device consists of a laser 1, a convex lens 2, a coaxial optical sensor 3, a side optical sensor 4, an acoustic sensor 5, a rear sensor 6, a welding pool 7, a material to be welded 8, a charge detection meter 9, a welding nozzle 10, The inert shielding gas 11 and the half mirror 12 are composed; the back sensor 6 is installed on the back of the material to be welded 8; the material to be welded 8 and the welding nozzle 10 are connected in series with a wire, and a charge detection meter 9 is connected in series in the middle of the wire; the side optical sensor 4 and the The acoustic sensor 5 is installed on one side of the welding puddle 7; the convex lens 2 and the coaxial optical sensor 3 are installed in the laser path transmitted horizontally; the half mirror 12 is installed directly above the welding puddle 7 and forms an angle of 45 degrees with the horizontal plane ; The inert shielding gas 11 is sprayed along the inside of the wel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com