A kind of anti-corrosion and anti-rust type post-tensioning method prestressed channel pressure slurry and preparation method thereof

A technology of channel grouting and post-tensioning method, which is applied in the field of building materials, can solve the problems of corrosion damage of prestressed steel bars, poor prestressed steel bar holding force, and insufficient grouting, and achieves reduced shrinkage, high strength, and slurry. Good flow performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

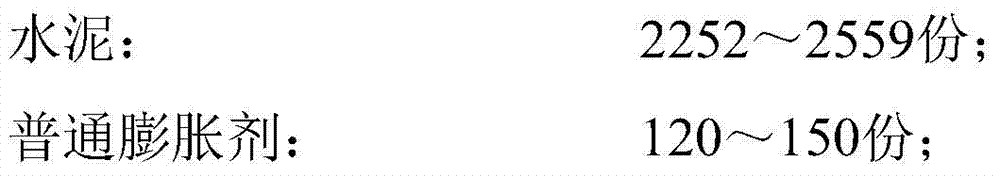

[0028] An anti-corrosion and anti-rust type post-tensioned prestressed tunnel pressure slurry, the formula of which is as follows:

[0029]

[0030] Its preparation method is as follows: Weigh each raw material component into a dry powder mixer and mix evenly, then move it into a cement mortar mixer, add 840g of mixing water at 20°C, stir for 1min at a slow speed, and then use a fast speed of 1000r / min. Stirring for 4 minutes, the product was discharged, and then the performance test of the grouting slurry was carried out under the ambient temperature of 20°C.

Embodiment 2

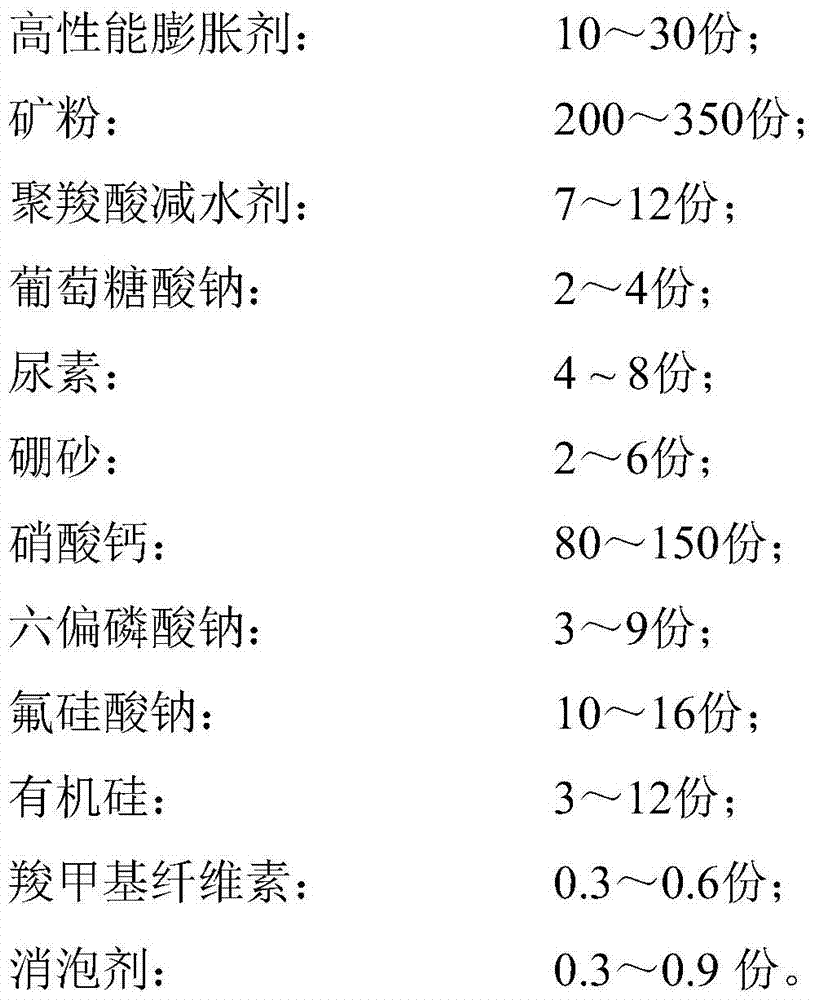

[0032] An anti-corrosion and anti-rust type post-tensioned prestressed tunnel pressure slurry, the formula of which is as follows:

[0033]

[0034]

[0035] The preparation method is as follows: Weigh each raw material component into a dry powder mixer and mix evenly, then move it into a cement mortar mixer, add 826g of mixing water at 23°C, stir for 1.5min at a slow speed, and then use a 1000r / min Stir at high speed for 4.5 minutes, discharge the product, and then carry out the performance test of the grouting slurry under the ambient temperature condition of 23°C.

Embodiment 3

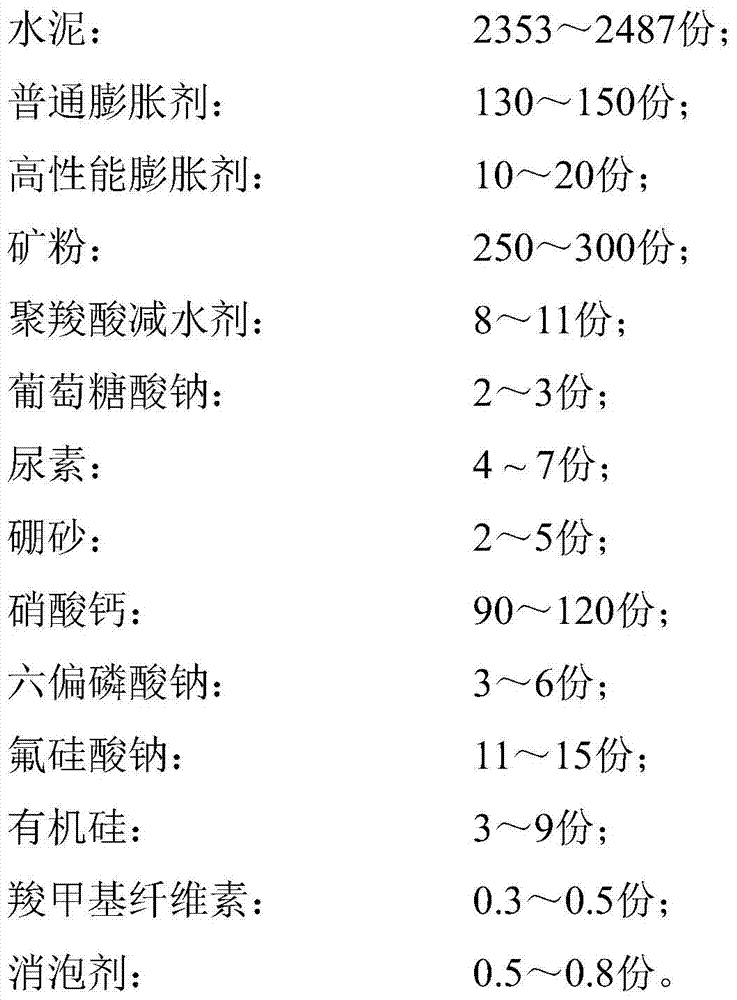

[0037] An anti-corrosion and anti-rust type post-tensioned prestressed tunnel pressure slurry, the formula of which is as follows:

[0038]

[0039]

[0040] Its preparation method is as follows: Weigh each raw material component into a dry powder mixer and mix evenly, then move it into a cement mortar mixer, add 760g of stirring water at 15°C, stir for 0.5min at a slow speed, and then use a 1000r / min Stir at high speed for 3 minutes, discharge the product, and then carry out the performance test of the grouting slurry under the ambient temperature of 15°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com