Water-based metal cutting fluid with high antibacterial property

An antibacterial and metal-based technology, which is applied in the field of water-based metal cutting fluid, can solve the problems of unsatisfactory lubricity, antibacterial and permeability, high cost and serious oil-based cutting fluid, and achieve the purpose of inhibiting the growth of bacteria and reducing the cost. Low, low toxicity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

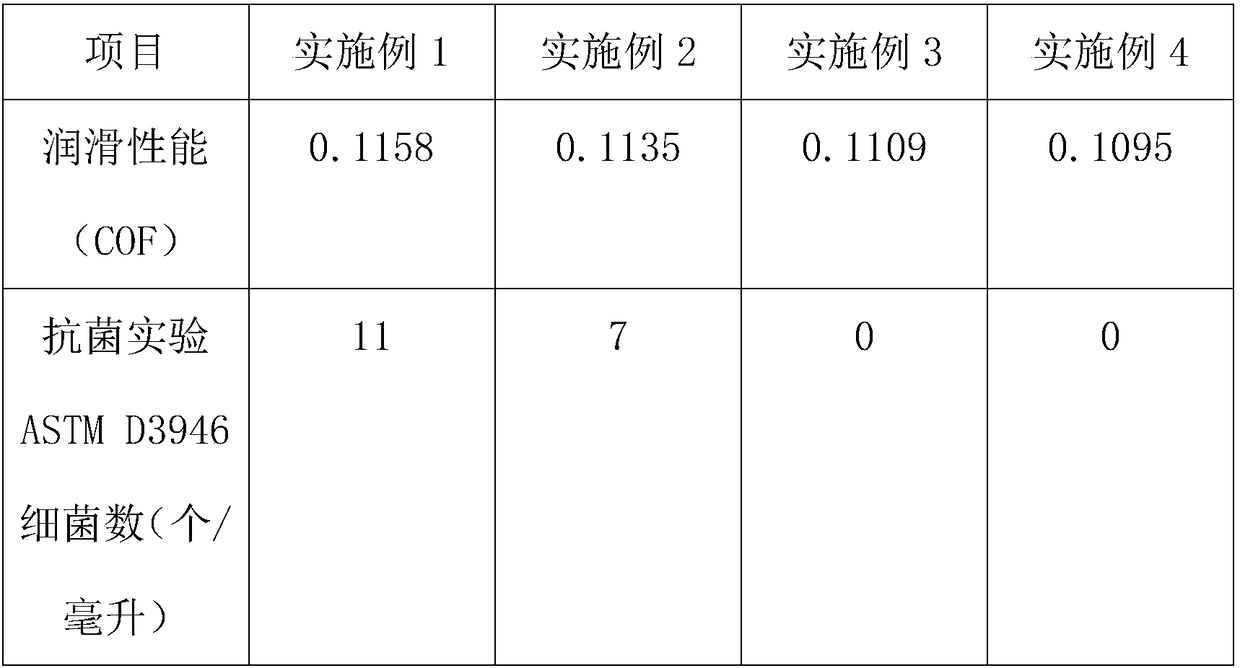

Examples

Embodiment 1

[0015] A water-based metal cutting fluid with strong antibacterial properties, comprising by weight: 10 parts of naphthenic base oil, 5 parts of synthetic fungicide, 5 parts of composite antirust agent, 13 parts of extreme pressure lubricant, fatty alcohol polyoxyethylene 5 parts of ether, 20 parts of sodium petroleum sulfonate, 0.2 parts of simethicone, 3 parts of fatty acid, 1 part of ethylene oxide cyclohexylamine, 10 parts of glycol ether, and 10 parts of water.

[0016] The synthesis method of synthetic fungicide: put dodecylamine, guanidine hydrochloride and diethylenetriamine in a device with reflux and stirring, start stirring, heat to 145°C, react for 230min, add ethylene glycol and water, cool out material, that is, a synthetic fungicide.

Embodiment 2

[0018] A water-based metal cutting fluid with strong antibacterial properties, comprising by weight: 30 parts of naphthenic base oil, 0.5 parts of synthetic fungicide, 12 parts of composite antirust agent, 6 parts of extreme pressure lubricant, fatty alcohol polyoxyethylene 15 parts of ether, 10 parts of sodium petroleum sulfonate, 2 parts of simethicone, 0.3 parts of fatty acid, 10 parts of ethylene oxide cyclohexylamine, 3 parts of ethylene glycol ether, 40 parts of water.

[0019] Synthetic method of synthetic fungicide: put laurylamine, guanidine hydrochloride and diethylenetriamine in a device with reflux and stirring, start stirring, heat to 150°C, react for 180min, add ethylene glycol and water, cool out material, that is, a synthetic fungicide.

Embodiment 3

[0021] A water-based metal cutting fluid with strong antibacterial properties, comprising by weight: 15 parts of naphthenic base oil, 4 parts of synthetic fungicide, 7 parts of composite antirust agent, 12 parts of extreme pressure lubricant, fatty alcohol polyoxyethylene 6 parts of ether, 18 parts of sodium petroleum sulfonate, 0.4 parts of simethicone, 2.5 parts of fatty acid, 2 parts of ethylene oxide cyclohexylamine, 8 parts of glycol ether, and 15 parts of water.

[0022] The synthesis method of the synthetic fungicide: put dodecylamine, guanidine hydrochloride and diethylenetriamine in a device with reflux and stirring, start the stirring, heat to 147°C, react for 190min, add ethylene glycol and water, cool out material, that is, a synthetic fungicide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com