Test method for dissolution time of solid powdery substance in solution

A detection method and solution technology, applied in the field of analysis and detection, can solve problems such as no method for measuring dissolution time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

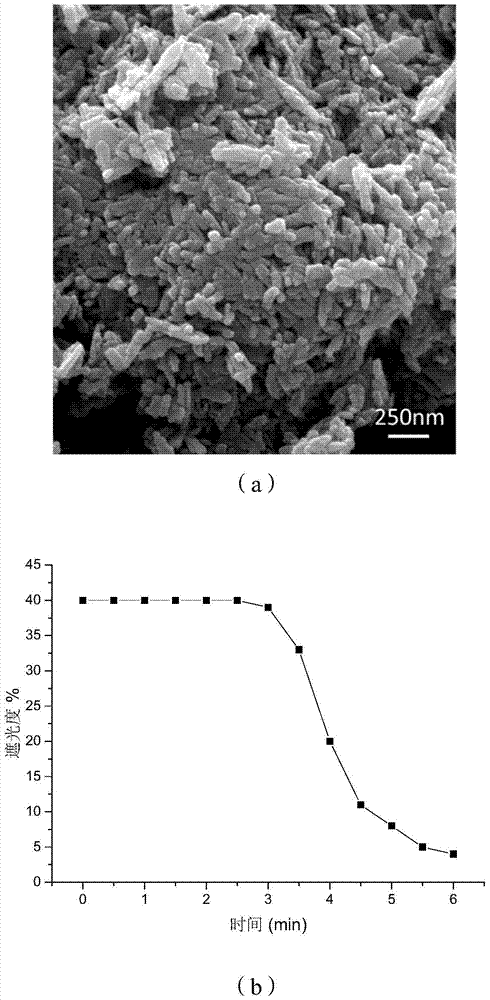

[0050] This embodiment detects the dissolution time of nano-scale copper oxide in the acidic copper electroplating solution, including the following steps: accurately weighing 3.00 g of copper oxide powder specially used for PCB production. Measure 250mL of the acidic electroplating copper solution with a graduated cylinder. The acidic electroplating copper solution is a plating solution used for PCB electroplating copper production provided by Guangdong Dongshuo Technology Co., Ltd., containing copper sulfate, sulfuric acid and organic additives. Test according to the aforementioned method (laser wavelength is 420nm), perform an optical measurement every 0.5min, and record the change of shading rate with time. Such as figure 1 (a) As shown by SEM, the three-dimensionality of copper oxide particles dedicated to PCB production is nanoscale; the shading rate changes with time as shown figure 1 Shown in (b), the dissolving time is 6min.

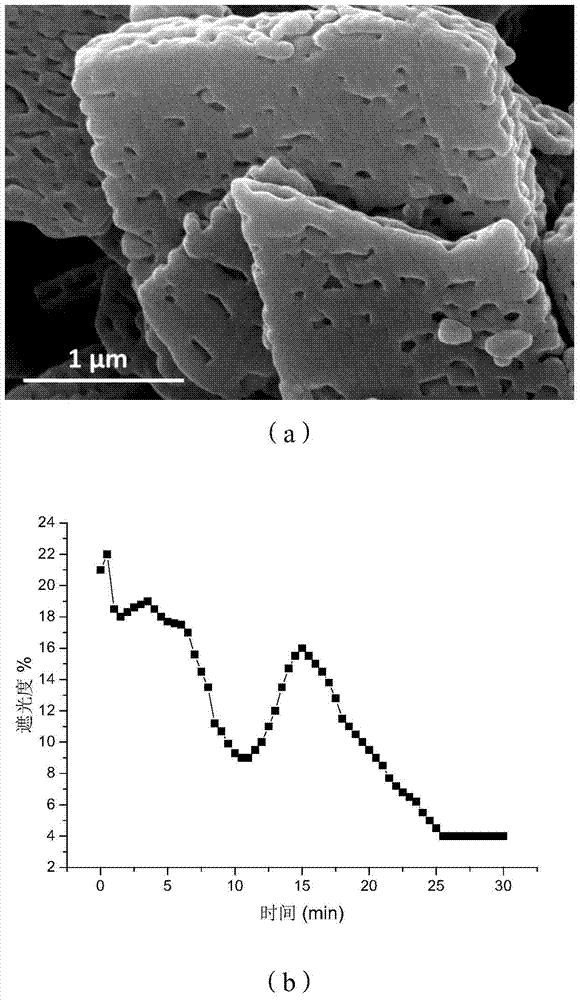

[0051] Detecting the dissolving time of...

Embodiment 2

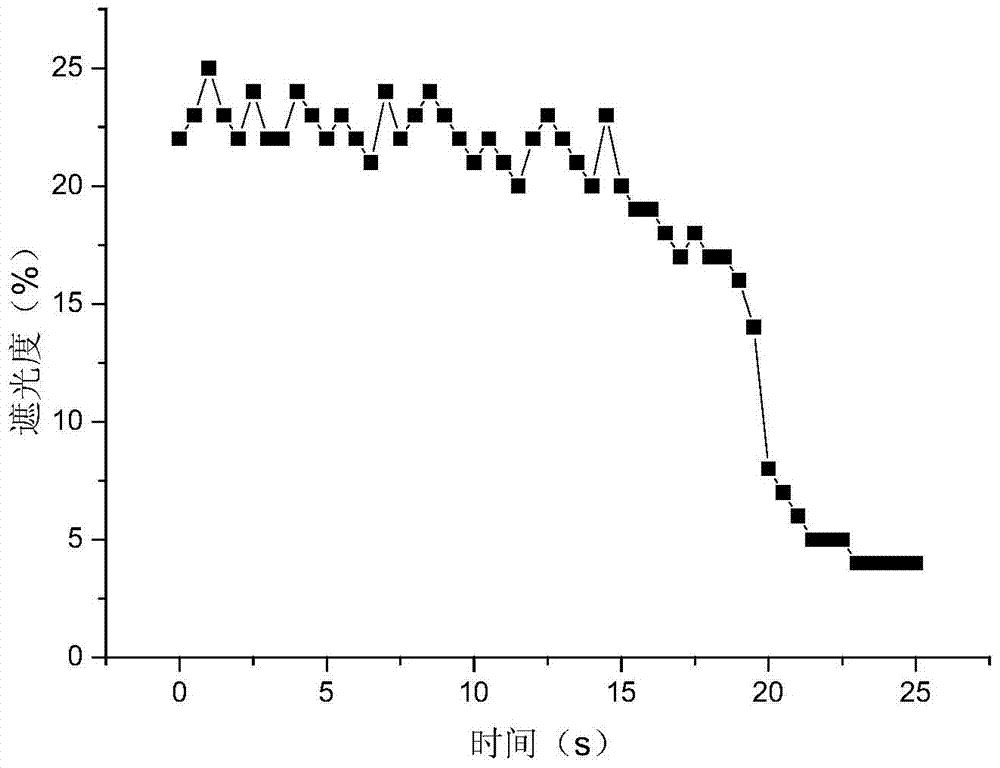

[0054] This example detects the dissolving time of polyphenylene amide in anhydrous acetone, including the following steps: accurately weighing 1.00 g of polyphenylene amide powder. Measure 50mL of anhydrous acetone with a graduated cylinder, test according to the aforementioned method (laser wavelength is 337nm), perform an optical measurement every 0.5s, and record the change of shading with time. In this example, acrylamide and acetone have strong absorption in the ultraviolet and infrared regions, and they are colorless and transparent in the visible region. Therefore, it is recommended to use a green laser to set the frequency of the laser in the visible region. The results of this experiment are as image 3 As shown, it takes 23s for polyacrylamide to completely dissolve in acetone.

Embodiment 3

[0056] This embodiment detects the dissolving time of sodium silicate powder in pure water, including the following steps: accurately weighing 2.50 g of sodium silicate powder. Measure 250mL of pure water with a graduated cylinder, test according to the above method (laser wavelength is 420nm), perform an optical measurement every 0.05s, and record the change of shading with time. Sodium silicate is very soluble in water, and the solubility in aqueous solution is extremely high, and after sodium silicate is dissolved in water, it becomes slightly yellow and obviously increases the viscosity of the solution. In this experiment scheme, the time interval of sampling is set to 0.05s, such as Figure 4 Shown, the dissolving time of described sodium silicate is 2.05s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com