Bactericidal composition comprising probenazole and thifluzamide and application of bactericidal composition

A bactericide composition, thifuramide technology, applied in the application, bactericide, biocide and other directions, can solve the problems of reduced control effect and control failure, and achieve the effects of prolonging service life, delaying drug resistance and environmental safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

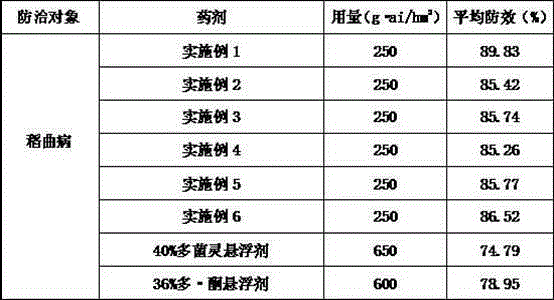

Examples

Embodiment 1

[0034] Example 1 (Preparation method of 60% Thiofuramide Thiabendazole WP)

[0035] Raw material formula: by mass percentage

[0036] Active ingredient Thiofuramide 10%

[0037] Active ingredient Thiabendazole 50%

[0038] NNO 6%

[0040] Silica 10%

[0041] Kaolin balance.

[0042] Preparation method: uniformly mix the above-mentioned substances, and pulverize the mixture through a jet mill to obtain a wettable powder.

Embodiment 2

[0043] Embodiment 2 (preparation method of 30% thiafuramide thiabendazole suspension)

[0044] Active Ingredient Thiofuramide 15%

[0045] Active ingredient Thiabendazole 15%

[0046] Sodium lignosulfonate 6%

[0047] BY140 4%

[0048] Xanthan Gum 0.1%

[0049] Propylene Glycol 1%

[0050] Phosphate ester defoamer 0.1%

[0051] water balance.

[0052] Preparation method: According to the formula, weigh each component in proportion, put it into a ball mill and mill it for 30 minutes, filter, pump it into the dispersion tank for 3 minutes, and then grind it fully with a sand mill to control the particle diameter of the solid component within 2 microns , and stir evenly after grinding to obtain a suspension product. Example 3 (Preparation method of 40% Thiofuramide Thiabendazole Water Dispersible Granules)

Embodiment 3

[0052] Preparation method: According to the formula, weigh each component in proportion, put it into a ball mill and mill it for 30 minutes, filter, pump it into the dispersion tank for 3 minutes, and then grind it fully with a sand mill to control the particle diameter of the solid component within 2 microns , and stir evenly after grinding to obtain a suspension product. Example 3 (Preparation method of 40% Thiofuramide Thiabendazole Water Dispersible Granules)

[0053] Active Ingredient Thiofuramide 5%

[0054]Active ingredient Thiabendazole 35%

[0055] Sodium methyl fatty acid amides benzene sulfonate 5%

[0057] Sodium lignosulfonate 6%

[0058] Attapulgite margin.

[0059] Preparation method: Mix thiafuramide, thiabendazole, sodium methyl fatty acid amide benzene sulfonate, sodium carbonate, and attapulgite evenly, and then pulverize it with a jet mill to a particle size of 5 μm to obtain a mother powder, and mix the mother powder with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com