Margarine without trans-fatty acid and preparation method of the margarine without trans-fatty acid

A technology of margarine and fatty acids, applied in the direction of edible oil/fat components, etc., can solve the problems of high production cost, high equipment requirements, complicated process, etc., and achieve the effect of saving time, low equipment requirements, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Add 3% (w / w) sunflower wax to 500g camellia oil, heat to 80°C and stir to make it fully melt. Immediately after that, put it into an ice-water bath to cool for 1 hour to make it solidify to obtain a grease gel. The grease gel was stored in a refrigerator at 4°C for later use.

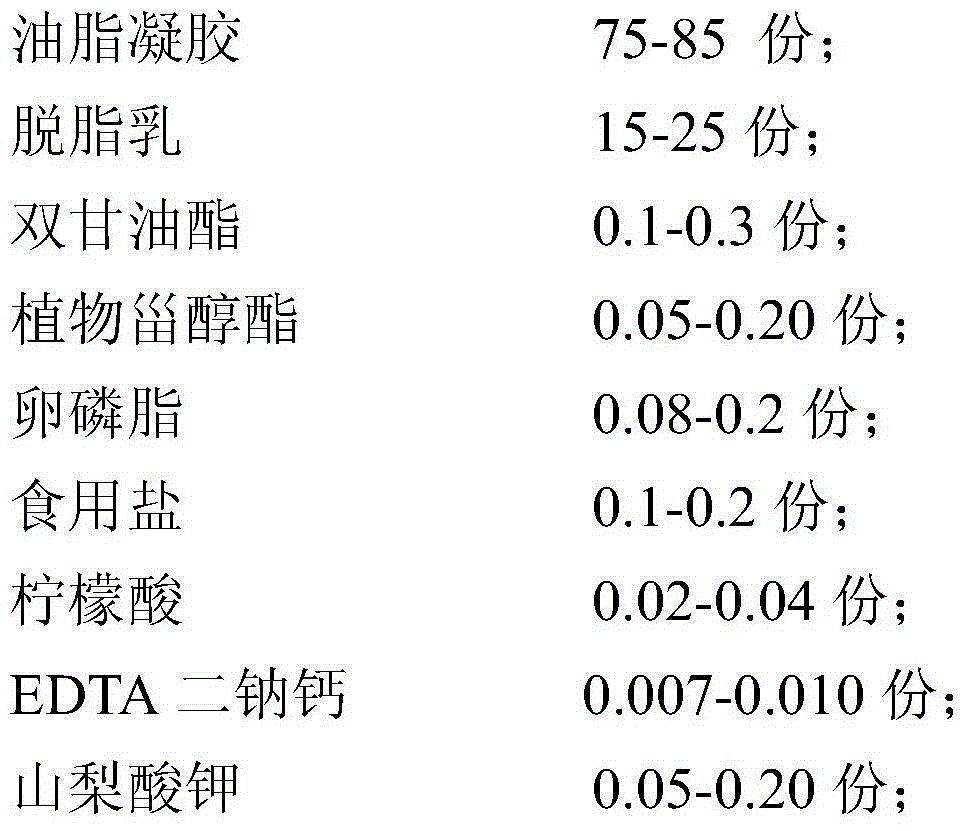

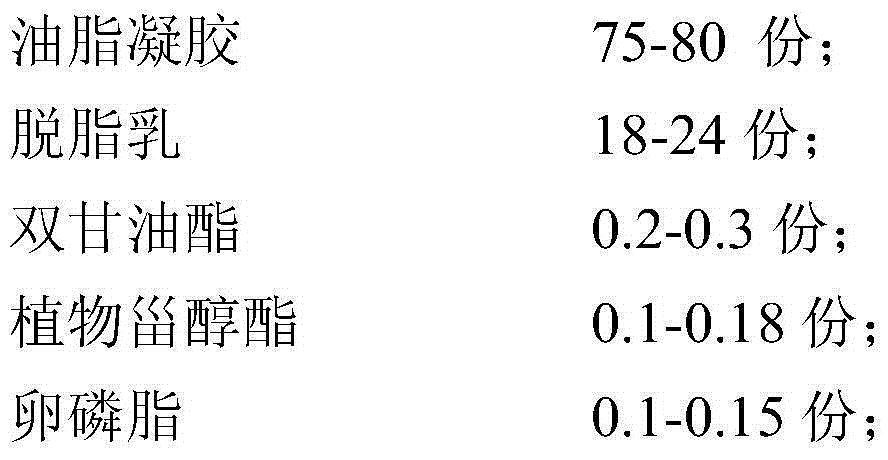

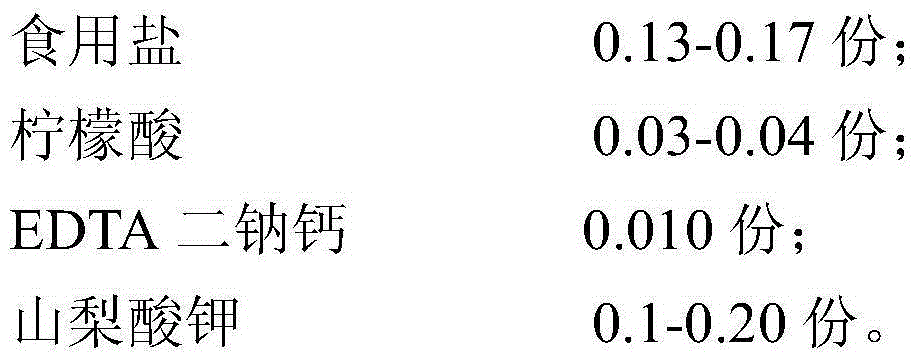

[0041] Margarine formula: 75.53g oil gel, 23.47g skim milk, 0.27g diglyceride, 0.17g phytosterol ester, 0.15g lecithin, 0.17g edible salt, 0.04g citric acid, 0.01g disodium calcium EDTA, Potassium sorbate 0.19g.

[0042] Preparation of the oil phase: mix the oil gel, diglyceride phytosterol ester and lecithin according to the formula ratio, heat to 80° C. in a water bath, stir well and set aside.

[0043] Preparation of the water phase: Mix skim milk, edible salt, citric acid, disodium calcium EDTA, and potassium sorbate according to the formula ratio, and stir well to completely dissolve them into a uniform water phase for later use.

[0044] Mixing and molding: Mix the oil phase and the wate...

Embodiment 2

[0046]Add 5% (w / w) palm wax into 500g palm oil, heat to 80 ℃ and stir, make it fully melt. Immediately after that, put it into an ice-water bath to cool for 1 hour to make it solidify to obtain a grease gel. The grease gel was stored in a refrigerator at 4°C for later use.

[0047] Margarine formula: 84.45g oil gel, 14.55g skim milk, 0.25g diglyceride, 0.19g phytosterol ester, 0.18g lecithin, 0.15g edible salt, 0.03g citric acid, 0.01g disodium calcium EDTA, Potassium sorbate 0.19g.

[0048] Preparation of the oil phase: mix the oil gel, diglyceride phytosterol ester and lecithin according to the formula ratio, heat to 75° C. in a water bath, stir well and set aside.

[0049] Preparation of the water phase: Mix skim milk, edible salt, citric acid, disodium calcium EDTA, and potassium sorbate according to the formula ratio, and stir well to completely dissolve them into a uniform water phase for later use.

[0050] Mixing and molding: Mix the oil phase and the water phase, a...

Embodiment 3

[0052] Add 8% (w / w) beeswax to 500g soybean oil, heat to 80°C and stir to make it fully melted. Immediately after that, put it into an ice-water bath to cool for 1 hour to make it solidify to obtain a grease gel. The grease gel was stored in a refrigerator at 4°C for later use.

[0053] Margarine formula: 81.49g oil gel, 17.61g skimmed milk, 0.29g diglyceride, 0.15g phytosterol ester, 0.19g lecithin, 0.13g edible salt, 0.03g citric acid, 0.01g disodium calcium EDTA, Potassium sorbate 0.10g.

[0054] Preparation of the oil phase: mix the oil gel, diglyceride phytosterol ester and lecithin according to the formula ratio, heat to 75° C. in a water bath, stir well and set aside.

[0055] Preparation of the water phase: Mix skim milk, edible salt, citric acid, disodium calcium EDTA, and potassium sorbate according to the formula ratio, and stir well to completely dissolve them into a uniform water phase for later use.

[0056] Mixing and molding: Mix the oil phase and the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com