Injection alprostadil fat emulsion and preparing method thereof

A technology of dil fat and alprostadil, which is applied in the field of alprostadil fat emulsion freeze-dried preparations, can solve problems such as widening particle size distribution, and achieve the effects of improving stability, reducing potential safety hazards, and increasing operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

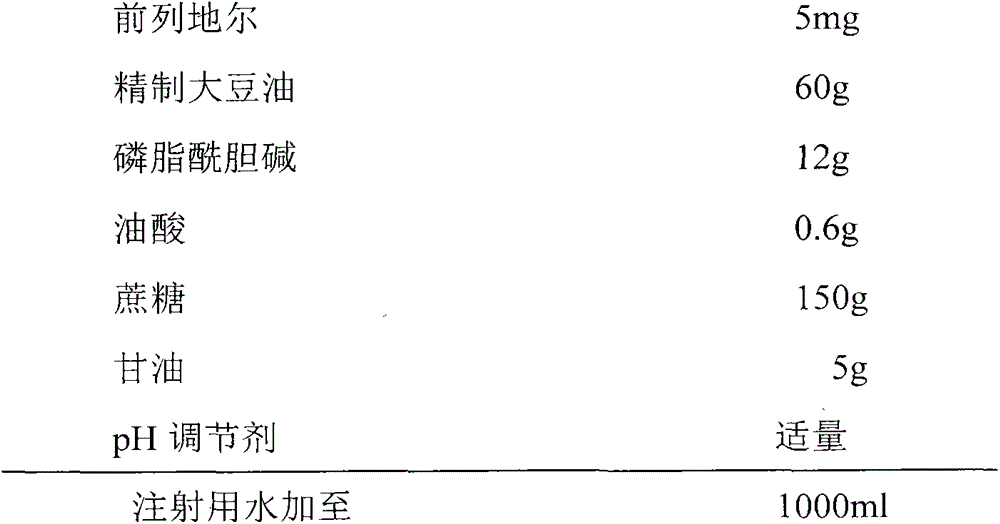

[0048] prescription:

[0049]

[0050] Process:

[0051] (1) Preparation of the water phase: add sucrose and glycerin into water to dissolve, heat to 65°C, and set aside;

[0052] (2) Preparation of the oil phase: heat the refined soybean oil to 65°C, add phosphatidylcholine (PC-98T, Shanghai Everett) and egg yolk phosphatidylglycerol (EPG, Shanghai Everett) to dissolve, and add the Dil, stir to dissolve;

[0053] (3) Preparation of colostrum: Add the oil phase of step (2) into the water phase of step (1), at a temperature of 65°C, high-speed shear dispersion, shear speed of 10,000 rpm, and time of 15 minutes, to form colostrum

[0054] (4) High-pressure homogenization: adjust the pH of the colostrum in step (3) to 6.9, and high-pressure homogenize 3 times with a microfluidizer at a pressure of 1000-1200 bar;

[0055] (5) Preliminary filtration: Prefilter the refined milk in step (4) through a 0.45 μm filter membrane;

[0056] (6) Sterile filtration: the emulsion obtain...

Embodiment 2

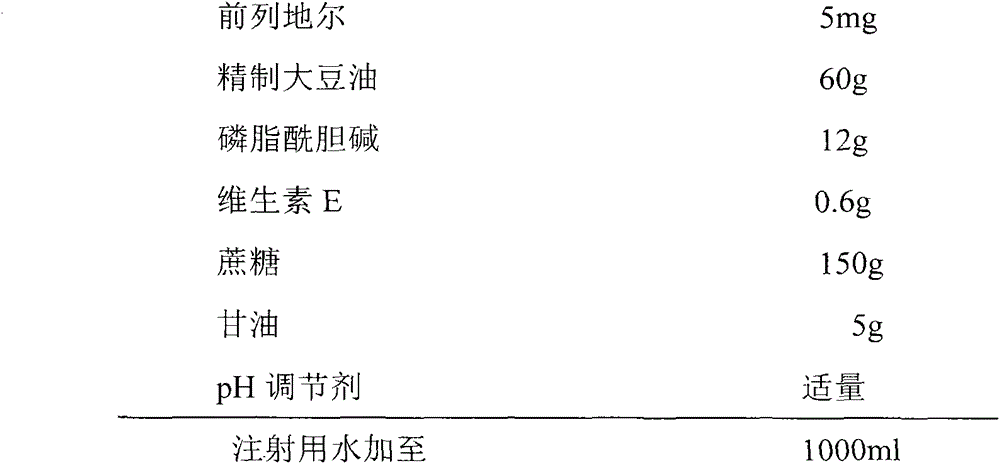

[0059] prescription:

[0060]

[0061] Process:

[0062] (1) Preparation of water phase: add sucrose into water to dissolve, heat to 65°C, and set aside;

[0063] (2) Preparation of the oil phase: heat the olive oil to 65°C, add phosphatidylcholine (PC-98T, Shanghai Aiweite) and egg yolk phosphatidylglycerol (EPG, Shanghai Aiweite) to dissolve respectively, add Qianliedi Er, stir to dissolve;

[0064] (3) Preparation of colostrum: Add the oil phase of step (2) into the water phase of step (1), at a temperature of 65°C, high-speed shear dispersion, shear speed of 10,000 rpm, and time of 15 minutes, to form colostrum

[0065] (4) High-pressure homogenization: Adjust the pH of the colostrum in step (3) to 7.1, and then use a microfluidizer for high-pressure homogenization 3 times at a pressure of 1000-1200 bar:

[0066] (5) Preliminary filtration: Prefilter the refined milk in step (4) through a 0.45 μm filter membrane;

[0067] (6) Sterile filtration: the emulsion obtaine...

Embodiment 3

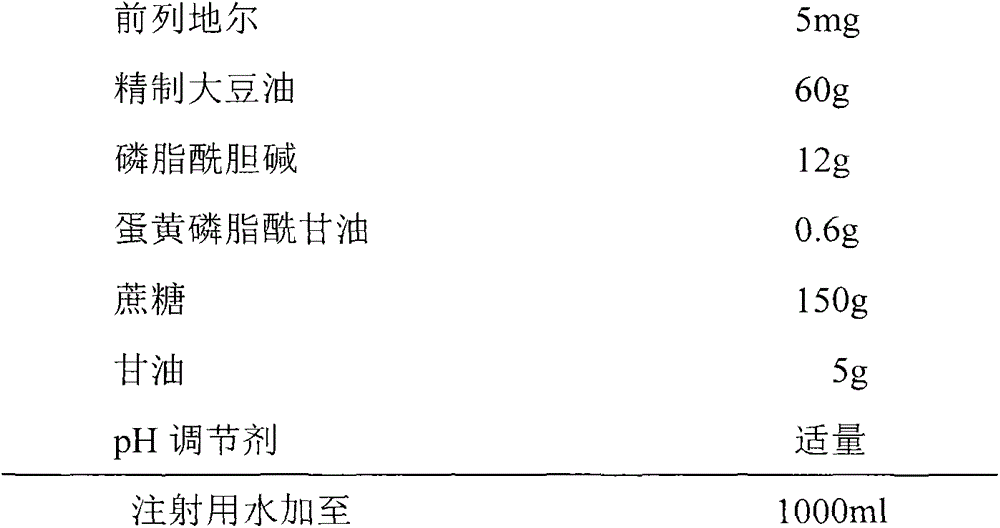

[0084] prescription:

[0085]

[0086]

[0087] Process:

[0088] (1) Preparation of water phase: add sucrose into water to dissolve, heat to 65°C, and set aside;

[0089] (2) Preparation of the oil phase: heat refined soybean oil to 65°C, add phosphatidylcholine (PC-98T) and egg yolk phosphatidylglycerol (EPG, Shanghai Everett) to dissolve, add alprostadil, and stir to make its dissolution;

[0090] (3) Preparation of colostrum: Add the oil phase of step (2) to the water phase of step (1), at a temperature of 65°C, high-speed shear dispersion, shear speed of 10,000 rpm, and time of 15 minutes, to form colostrum.

[0091] (4) High-pressure homogenization: adjust the pH of the colostrum in step (3) to 7.2, and high-pressure homogenize 3 times with a microfluidizer at a pressure of 1000-1200 bar;

[0092] (5) Preliminary filtration: Prefilter the refined milk in step (4) through a 0.45 μm filter membrane;

[0093] (6) Sterile filtration: the emulsion obtained in step (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com