Preparation method of nano silver/poly dopamine composite membrane

A polydopamine, composite membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., to achieve the effects of high water flux, good antibacterial properties, and high dye separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Step 1. Preparation of polyethersulfone base membrane: dissolving polyethersulfone in N,N-dimethylformamide to prepare a casting solution containing polyethersulfone with a mass concentration of 16%, stirring at 60° C. for 4 hours, And stand at 60°C for defoaming for 4 hours, after cooling to room temperature, pour the casting solution on the glass plate to scrape the film, then put it in a water bath at 25°C to solidify to form a film, take it off the glass plate and soak it in deionized water After 24 hours, a polyethersulfone-based membrane was obtained.

[0015] Step 2. Preparation of nano-silver / polydopamine composite membrane: Tris-HCl buffer solution with pH=8.5 is used to dissolve dopamine, and the prepared polyethersulfone ultrafiltration membrane is soaked in 0.2% dopamine buffer solution by mass percentage Shake continuously for 4 hours, so that polydopamine can be fully deposited on the surface of the membrane, take out the membrane and simply rinse it with ...

Embodiment 2

[0018] Step 1, the preparation of the polyethersulfone base membrane is the same as in Example 1.

[0019] Step 2. Preparation of nano-silver / polydopamine composite membrane: basically the same as in Example 1, the only difference being that the time of airtight reaction at room temperature was increased from 2h to 12h, and nano-silver / polydopamine composite membrane 2 was finally obtained.

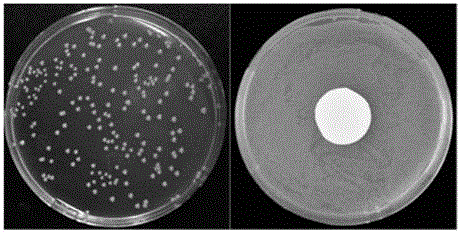

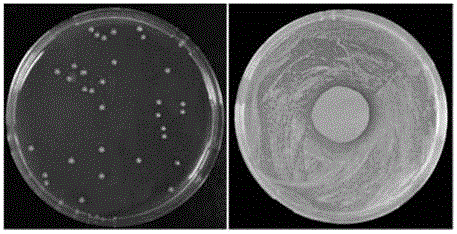

[0020] The water flux of the composite membrane 2 that present embodiment 2 makes is 402.50L / (m 2 hMPa). The rejection rate of sodium orange yellow (Mw=452.4Da, mass percentage 0.01%) aqueous solution is 61.41%. Figure 4 It is the composite film 2 plate coating antibacterial experiment and the effect diagram of the inhibition zone experiment of the composite film 2 prepared in this embodiment 2.

Embodiment 3

[0022] Step 1, the preparation of the polyethersulfone base membrane is the same as in Example 1.

[0023] Step 2. Preparation of nano-silver / polydopamine composite film: basically the same as in Example 1, the only difference being that the time of airtight reaction at room temperature was increased from 2h to 36h, and nano-silver / polydopamine composite film 3 was finally obtained.

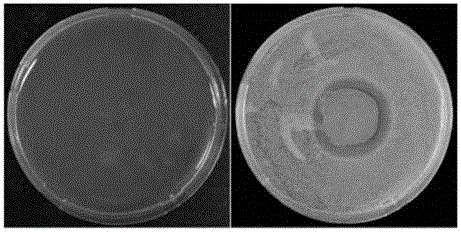

[0024] The water flux of the composite membrane 3 that present embodiment 3 makes is 282.85L / (m 2 hMPa). The rejection rate of sodium orange yellow (Mw=452.4Da, mass percentage 0.01%) aqueous solution is 71.65%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com