Preparation method for cadmium sulfide quantum dot/carbon nanotube photocatalyst taking polyvinylpyrrolidone as dispersant

A technology of polyvinylpyrrolidone and carbon nanotubes, which is applied in the field of preparation of cadmium sulfide quantum dots/carbon nanotube photocatalysts, can solve problems affecting practical applications, complex synthesis methods, etc., and achieves easy control of preparation conditions, simple preparation methods, The effect of high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Pretreatment of carbon nanotubes

[0020] Put the multi-walled carbon nanotubes in a three-neck flask, add 100ml of concentrated nitric acid with a concentration of 65%, heat and stir at 115°C for 8.5h under reflux, after cooling, wash with water until neutral, filter and dry for later use.

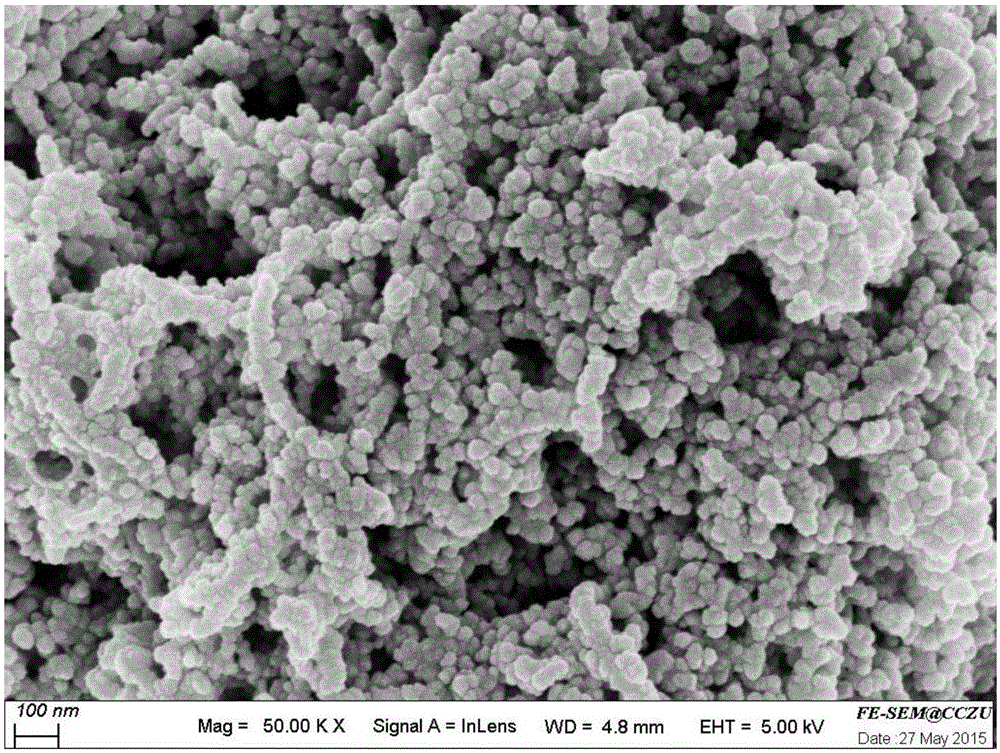

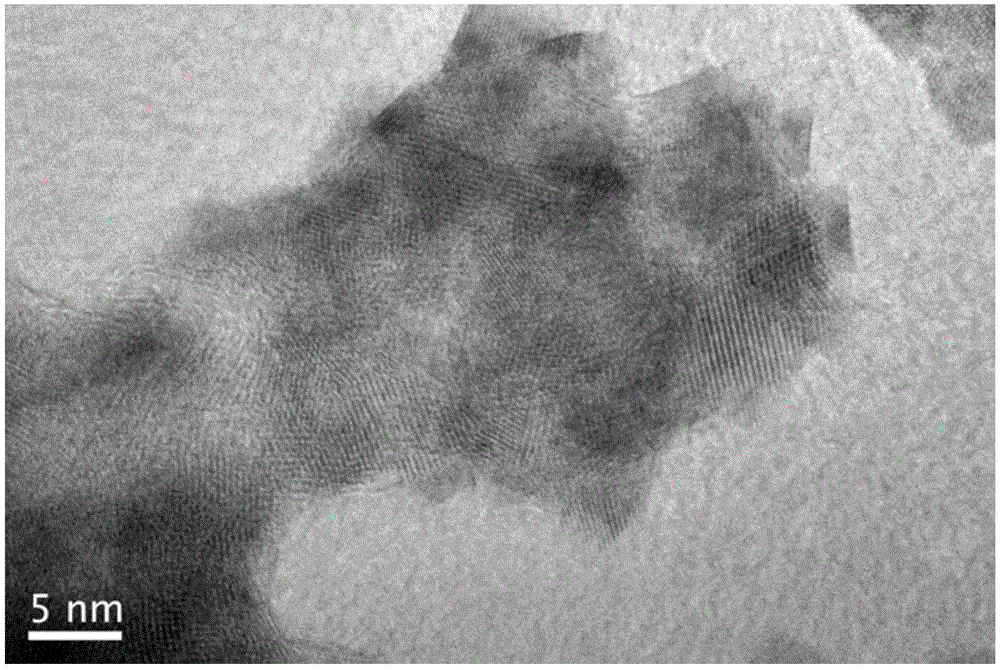

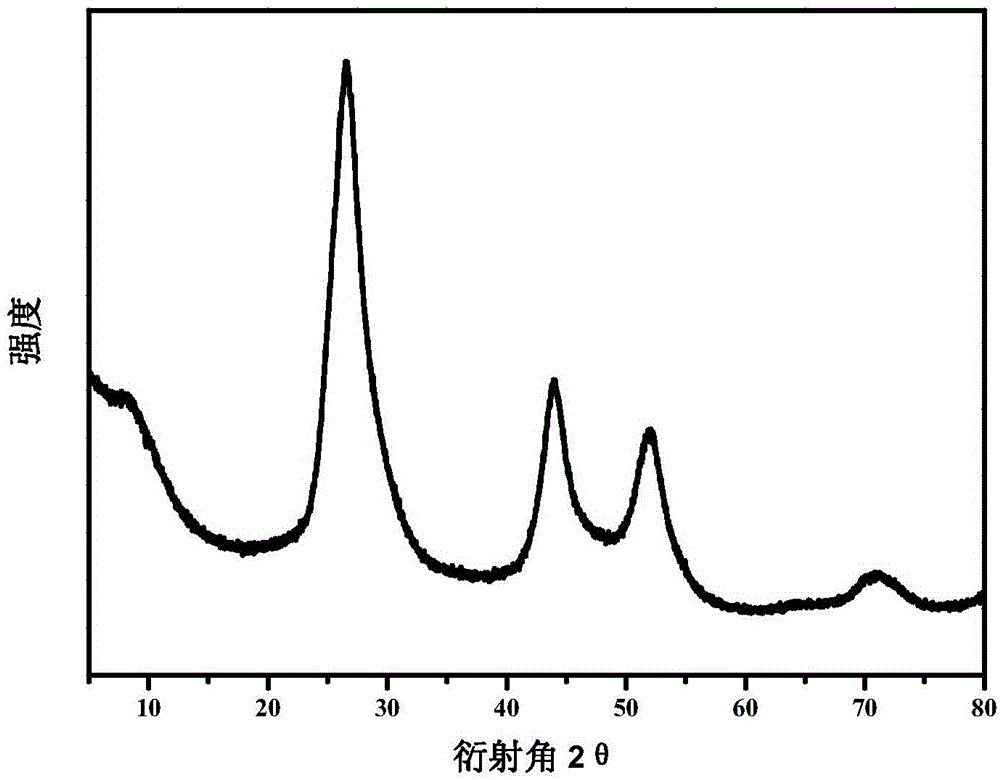

[0021] (2) Preparation of cadmium sulfide quantum dot / carbon nanotube composite photocatalyst

[0022] Place 0.1 g of multi-walled carbon nanotubes prepared in (1) in a 100 ml beaker, add 65 ml of ethylene glycol, weigh 0.0302 g of cadmium acetate, 0.0151 g of thioacetamide and 0.0301 g of polyvinylpyrrolidone and add them to the beaker , ultrasonically stirred for 1.5h, and then transferred the above solution to a 200ml hydrothermal reaction kettle, reacted at 120°C for 24h, cooled, filtered with suction, washed with ethanol and water successively, and dried to obtain the product.

Embodiment 2

[0024] (1) Pretreatment of carbon nanotubes

[0025] Put the multi-walled carbon nanotubes in a three-necked flask, add 150ml of concentrated nitric acid with a concentration of 65%, heat and stir at 125°C for 9.5h under reflux, after cooling, wash with water until neutral, filter and dry for later use.

[0026] (2) Preparation of cadmium sulfide quantum dot / carbon nanotube composite photocatalyst

[0027] Place 0.1g of multi-walled carbon nanotubes prepared in (1) in a 100ml beaker, add 75ml of ethylene glycol, weigh 0.05g of cadmium acetate, 0.02g of thioacetamide and 0.025g of polyvinylpyrrolidone and add them to the beaker , ultrasonically stirred for 1 hour, and then transferred the above solution to a 200ml hydrothermal reaction kettle, reacted at 80°C for 20 hours, cooled, filtered with suction, washed with ethanol and water successively, and dried to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com