Application of microgroove forming mold in preparation of silicone rubber with microgroove pattern on surface

A technology of forming molds and micro-grooves, applied in the field of medical materials, can solve the problems of easy formation of capsule, displacement of prosthesis contracture, rupture, etc., to increase water contact angle, reduce capsule contracture, and reduce hydrophilicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 Preparation of ordinary silicone rubber and silicone rubber with micro-groove patterns on the surface

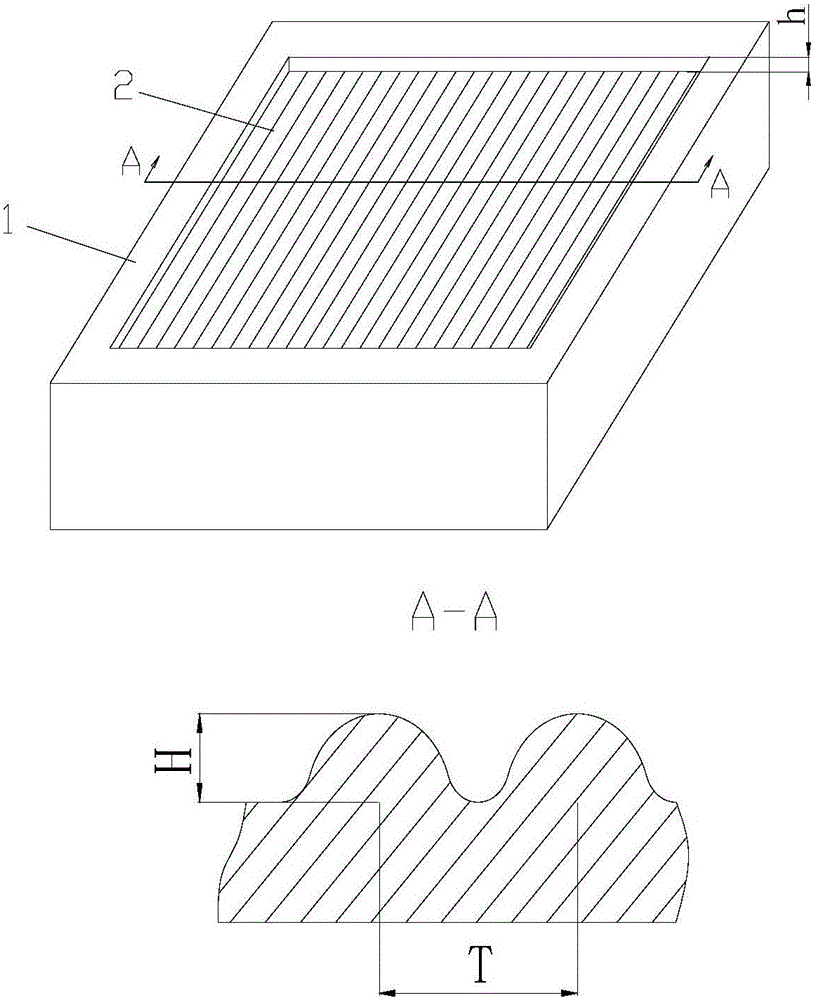

[0026] The structure diagram of the micro groove forming die is as follows figure 1 As shown, the concave mold 1 is included, and the bottom of the concave mold 1 is provided with microscopic protrusions 2 for forming micro grooves. The microscopic protrusions 2 can be distributed in columns or rows, and of course it can be in any direction, that is, with the concave mold 1 The length and width directions of the dimples are not parallel. In this embodiment, they are preferably parallel to the width direction of the die 1, that is, they are distributed in a row, which is convenient for processing; in order to achieve a better molding effect, after experiments, the microscopic protrusions should be in a certain shape. The effect of the regular distribution of period T and H peaks will be better, among which the optimal peak value H is 4-6 μm, and the period T ...

Embodiment 2

[0030] Embodiment 2 SR and P-SR physical and chemical performance detection

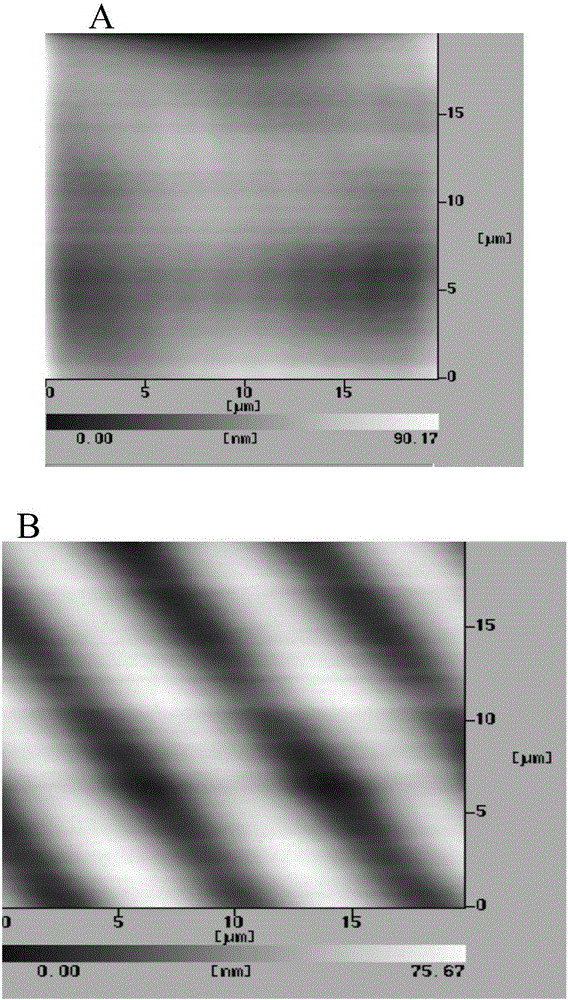

[0031] Cut the material into 1cm×1cm squares, soak them in a beaker filled with 75% alcohol, place them in an ultrasonic cleaner, set parameters: power 20w, time 5min. After cleaning, place them in a constant temperature incubator at 37°C to dry, and measure the water contact angle after completely drying and cooling. The measurement environment room temperature is 28°C and the humidity is 65%. In order to measure the data accurately as soon as possible, the time used is generally within 30S. Place the test material flat on the stage of the water contact angle measuring instrument, use deionized water as the medium, randomly select 3 different parts on the SR surface, and select 3 different micro-groove areas on the P-SR, and measure 3 data point, and finally calculate the average value of the two groups of samples, the result is as follows Figure 4 As shown, the water contact angle of SR is small...

Embodiment 3

[0032] Example 3 SR and P-SR Cytocompatibility Test

[0033] Human dermal fibroblasts were used for testing, and the culture medium was DMEM culture medium containing 10% fetal bovine serum. First, the cytoskeleton structure of fibroblasts on SR and P-SR was tested by immunofluorescence method, and the specific steps were as follows:

[0034] (1) Inoculate human dermal fibroblasts in 24-well plates covered with SR and P-SR materials, inoculate 4×10 4 cells / well in 5% CO 2 , 37 ℃ constant temperature incubation for 48h;

[0035] (2) Discard the stock solution, wash with PBS 2-3 times; fix cells: 3.7% formaldehyde, 15 min; punch: 0.1% Triton X-100 / PBS, 15 min; seal: 5% goat serum, room temperature for 15 min; incubate the cytoskeleton: Actin-Tracker Green, room temperature for 1h in the dark; wash once with PBS in the dark; incubate the nuclei with Hoechst33342 for 5min;

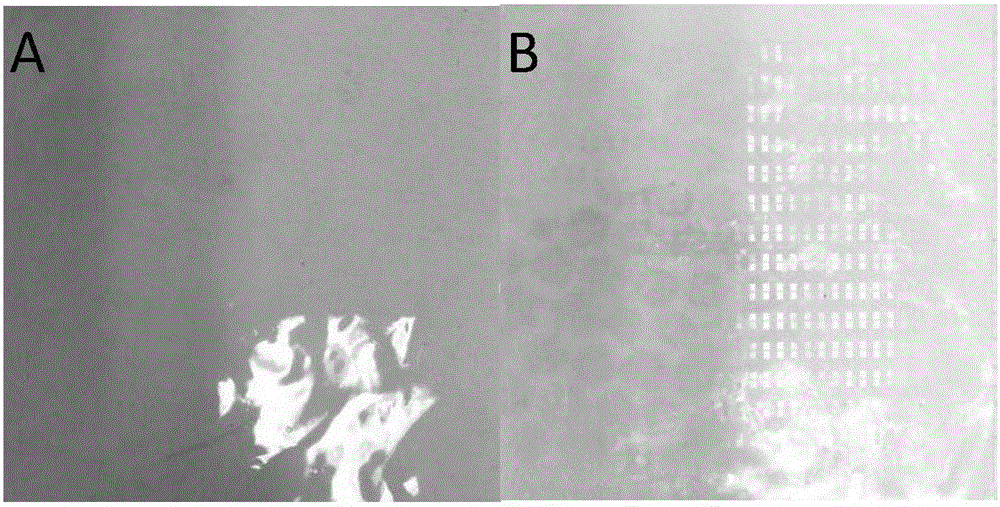

[0036] (3) Mount the slide with 50% glycerol, and check the skeleton structure layout of the cells on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com