Anti-frosting method with low energy consumption

A low energy consumption, anti-frosting technology, applied in micro-structure technology, micro-structure devices, manufacturing micro-structure devices, etc., can solve the problem of not mentioning the problem of anti-frost, and achieve the effect of delaying the spreading speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Clean and remove organic grease and inorganic impurities on the surface of the copper sheet.

[0025] (2) Take the mixed solution of cobalt chloride and urea as the reaction solution, immerse the copper sheet in it, and put it in a water bath at 60 °C for 11 h. Take it out, wash it and dry it, put it in an oven with 5 μL of fluorosilane and bake it at 120 °C for 2 hours, and then you can get a nanocone array structure surface with droplet self-dispelling and bouncing properties (hereinafter referred to as "nanostructure surface") .

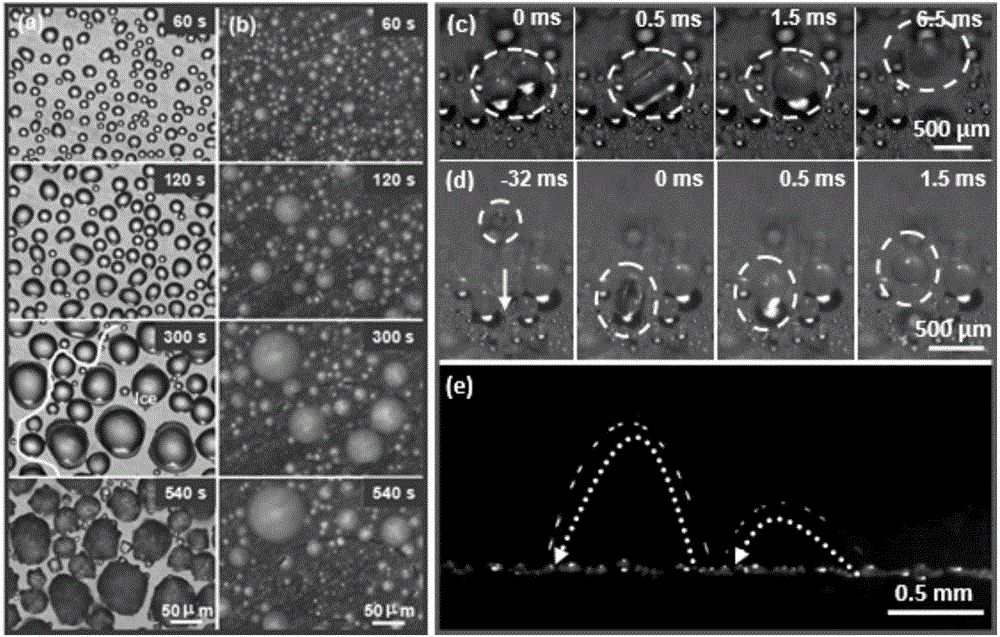

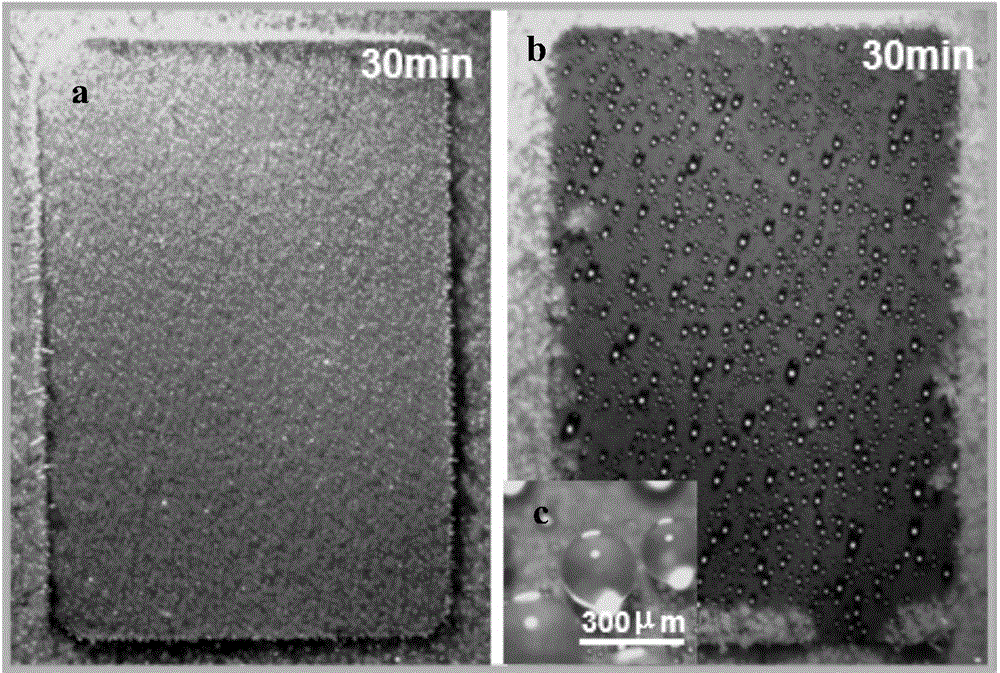

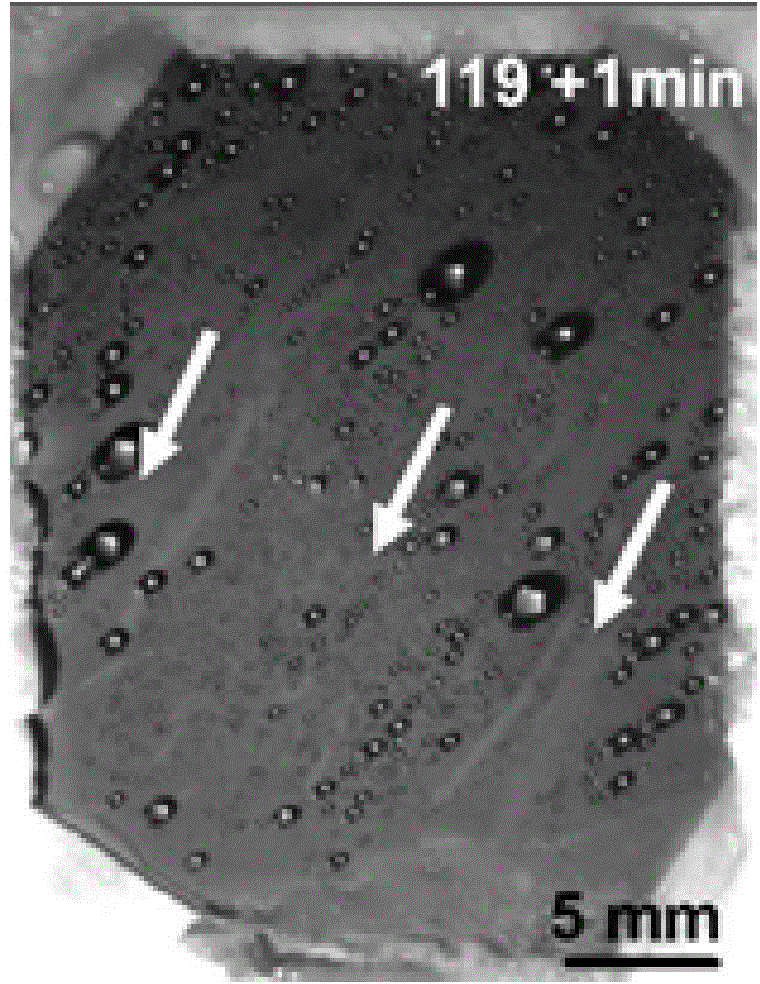

[0026] (3) see figure 2 Shown is the comparison of frosting on the nanostructured surface and the blank copper sheet (ordinary smooth copper sheet) under the conditions of high humidity (relative humidity 60%, ambient temperature 23 ℃) and wall temperature -10 ℃. It can be seen that on the surface of the nanostructure, there are only a small amount of frost crystals at the edge at 30 minutes, and the frost crystals cover an area of ...

Embodiment 2

[0029] (1) Clean and remove organic grease and inorganic impurities on the surface of the copper sheet.

[0030] (2) Take the mixed solution of cobalt chloride and urea as the reaction solution, immerse the copper piece in it, and put it in a water bath at 60 °C for 6~7 h. After taking it out for cleaning and drying, put it in an oven with 5 μL of fluorosilane and bake it at 120 °C for 2 h to obtain a nanoneedle array structure surface with droplet self-dispelling and bouncing properties.

Embodiment 3

[0032] (1) Clean and remove organic grease and inorganic impurities on the surface of the copper sheet.

[0033] (2) Take the mixed solution of zinc nitrate and sodium hydroxide as the reaction solution, immerse the copper piece in it, and put it in a water bath at 60 °C for 2 h. After taking it out, washing it and blowing it dry, put it in an oven with 5 μL of fluorosilane and bake it at 120 °C for 2 h to obtain a nanoflower structure surface with droplet self-dispelling and bouncing properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com