Concrete annular pole and preparation method thereof

A technology of concrete and powder concrete, which is applied in the field of building materials to achieve the effects of good freeze-thaw resistance and acid, alkali and salt corrosion resistance, low cost and reduced weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] Correspondingly, the embodiment of the present invention also provides a method for preparing a concrete ring-shaped electric pole, including the following steps:

[0034] S01. take each component by the formula of above-mentioned concrete annular electric pole;

[0035] S02. After mixing steel fiber, polypropylene fiber and river sand, Portland cement, silicon powder and mineral powder are added to further mix to form a mixed material, and high-efficiency water reducer and water are added to the mixed material to form a superplasticizer. high performance powder concrete;

[0036] S03. The above-mentioned ultra-high performance powder concrete is evenly distributed in the steel mesh concrete pole mold with a protective layer thickness of 8-12 mm through a distributing machine, and is densely formed by a centrifugal process. After a static stop for 1-2 hours, it is placed in a steam curing kiln The temperature is raised in the middle, and the curing temperature is 85-95...

Embodiment 1

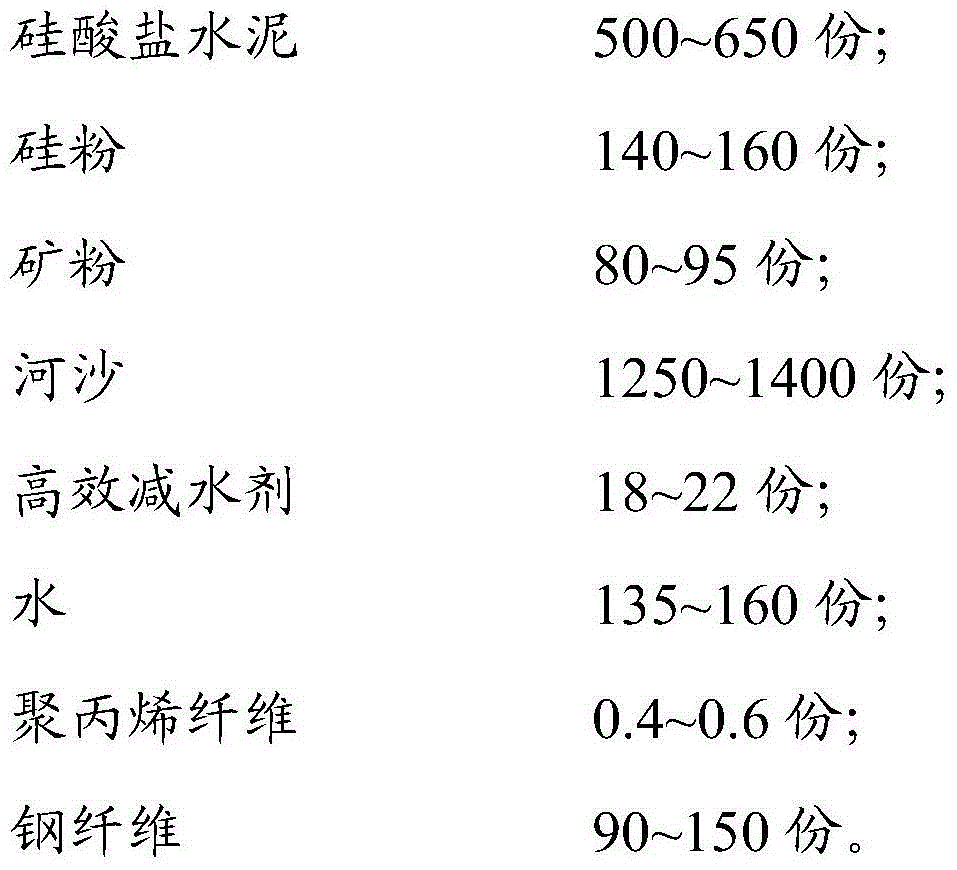

[0043] A concrete annular pole, comprising the following formula components in the following parts by weight:

[0044]

[0045] Wherein, the Portland cement is 52.5 grade Portland cement with a particle size of 30-60 μm; the particle size of the silica fume is 0.18 μm, wherein SiO 2 The mass percentage content is more than 85%; the mineral powder is above S95 grade mineral powder with a particle size of 10-30 μm; the particle size of the river sand is 0.16-4.75 mm; the water reducing agent of the high-efficiency water reducer Rate > 30%. The steel mesh is made of Ф≥3.0mm prestressed steel wire as the main reinforcement and Ф≥2.0mm high-strength wire as the circumferential reinforcement. The thickness of the protective layer is 8-12 mm, and the distance between the two ends of the steel mesh is 50-100 cm. 10-30mm, and the circumferential rib spacing at other positions is 40-80mm.

[0046] The preparation method of above-mentioned concrete annular pole, comprises the steps:...

Embodiment 2

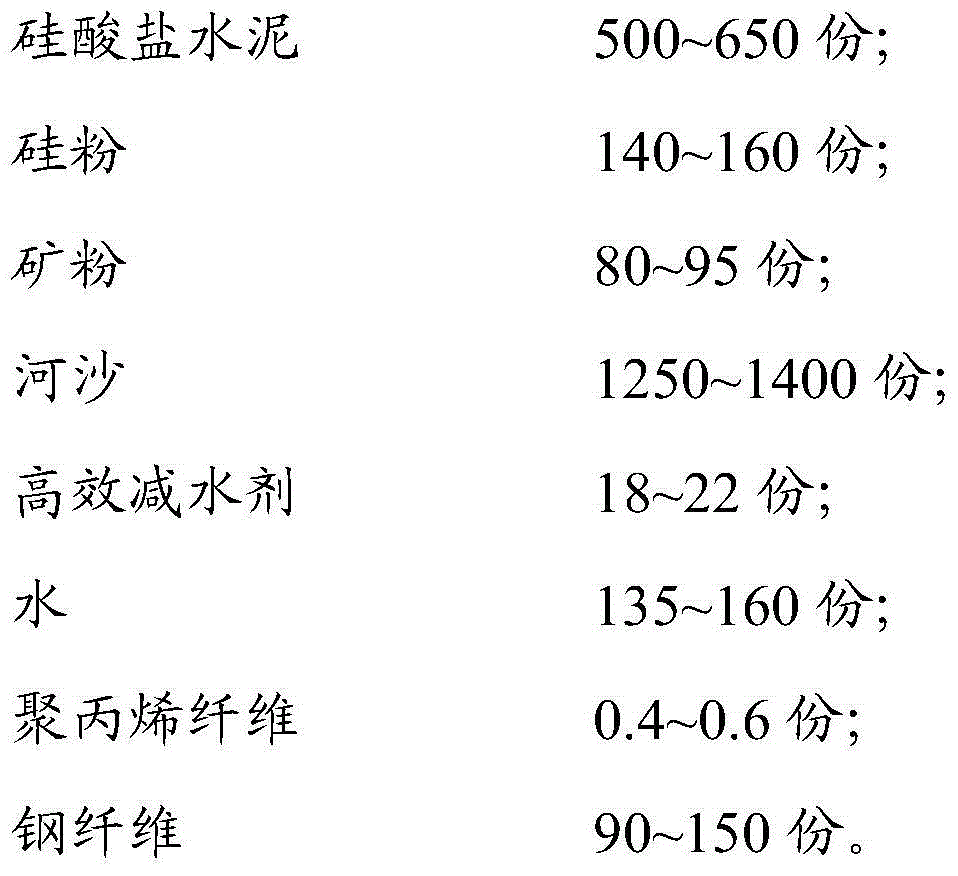

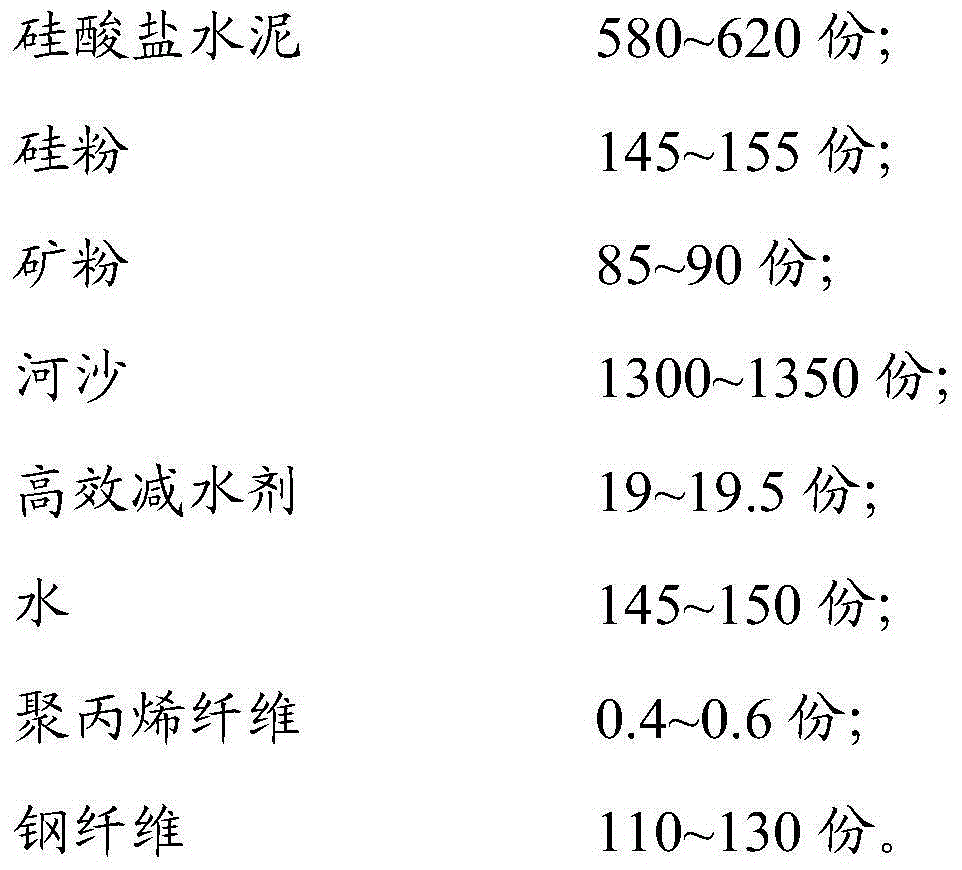

[0051] A concrete annular electric pole, comprising the following formula components in the following parts by weight: 550 parts of Portland cement;

[0052]

[0053] Wherein, the Portland cement is 52.5 grade Portland cement with a particle size of 30-60 μm; the particle size of the silica fume is 0.18 μm, wherein SiO 2 The mass percentage content is more than 85%; the mineral powder is above S95 grade mineral powder with a particle size of 10-30 μm; the particle size of the river sand is 0.16-4.75 mm; the water reducing agent of the high-efficiency water reducer Rate > 30%. The steel mesh is made of Ф≥3.0mm prestressed steel wire as the main reinforcement and Ф≥2.0mm high-strength wire as the circumferential reinforcement. The thickness of the protective layer is 8-12 mm, and the distance between the two ends of the steel mesh is 50-100 cm. 10-30mm, and the circumferential rib spacing at other positions is 40-80mm.

[0054] The preparation method of above-mentioned conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slump | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com