High-softening-point ultra-high-molecular-weight polyethylene alloy material and preparation method thereof

An ultra-high molecular weight and alloy material technology, which is applied in the field of ultra-high molecular weight polyethylene alloy materials and its preparation, can solve the problems of low Vicat softening point and cannot withstand high temperature and rebound speed, and achieves high Vicat softening point and good low temperature. The effect of high performance and heat distortion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

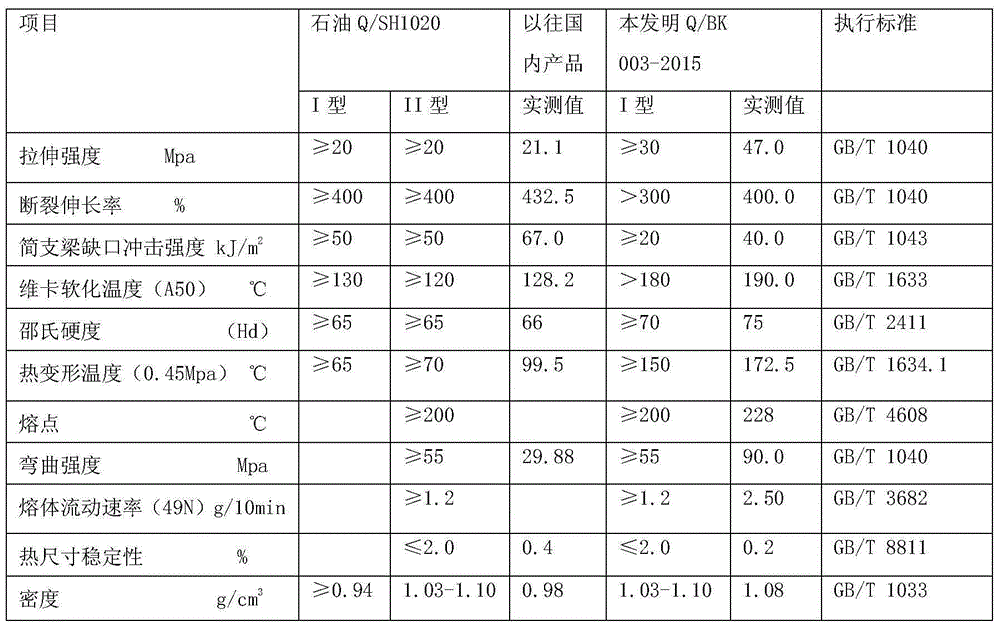

Examples

Embodiment 1

[0018] The maleic anhydride grafting of 50g ultra-high molecular weight polyethylene resin, 30g nylon 6 resin, 5.5g inorganic nano-calcium, 2g compatibilizer KT-3, 0.5g chain extender SMC-3010, 12g ultra-high molecular weight polyethylene UHMWPE-g-MAH, the above-mentioned nylon 6 and inorganic nano-materials are dried in a dryer until the water content reaches less than 0.1%; then the dried nylon 6 resin, inorganic nano-materials, and the above-mentioned chain extender , compatibilizer and UHMWPE-g-MAH were mixed in a high-speed mixer for 5 minutes, and mixed evenly; the above-mentioned mixture was added to a twin-screw extruder for melting and mixing, plasticized, extruded and granulated, and the twin-screw process temperature was 210°C , the extrusion speed is 100r / min, and the alloy material is obtained, and the obtained material is prepared in an injection machine at a process temperature of 250°C to prepare a sample.

Embodiment 2

[0020] Weigh 45g ultra-high molecular weight polyethylene resin, 32g nylon 6 resin, 7g inorganic nano-calcium, 2g compatibilizer KT-5, 0.5g chain extender SMC-3010, 13.5g maleic anhydride grafted ultra-high molecular weight polyethylene The above-mentioned nylon 6 resin and inorganic nanomaterials are dried in a dryer until the water content reaches less than 0.1%; then the dried nylon 6 resin, inorganic nanomaterials, and the above-mentioned chain extenders and compatibilizers are dried Mix with UHMWPE-g-MAH in a high-speed mixer for 5 minutes, and mix evenly; put the above-mentioned mixture into a twin-screw extruder for melting and mixing, plasticize and extrude to pelletize, the twin-screw process temperature is 240 ° C, and the extrusion speed The alloy material is obtained at 280r / min, and the obtained material is prepared in an injection machine at a process temperature of 250°C to prepare a sample.

Embodiment 3

[0022] The maleic anhydride grafting of 46g ultra-high molecular weight polyethylene resin, 32g nylon 6 resin, 6.5g inorganic nano-calcium, 3g compatibilizer KT-3, 0.5g chain extender SMC-3010, 12g ultra-high molecular weight polyethylene The above-mentioned nylon 6 resin and inorganic nanomaterials are dried in a dryer until the water content reaches less than 0.1%; then the dried nylon 6 resin, inorganic nanomaterials, and the above-mentioned chain extenders and compatibilizers are dried Mix with UHMWPE-g-MAH in a high-speed mixer for 5 minutes, and mix evenly; put the above-mentioned mixture into a twin-screw extruder for melting and mixing, plasticize and extrude to granulate, the twin-screw process temperature is 235 ° C, and the extrusion speed The alloy material is obtained at 230r / min, and the obtained material is prepared in an injection machine at a process temperature of 250°C to prepare a sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Vicat softening temperature | aaaaa | aaaaa |

| Heat distortion temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com