A kind of PET protective film and preparation method thereof

A protective film and film technology, applied in the field of PET protective film and its preparation, can solve the problems of harming the environment, easy to produce residual glue, poor peelability, etc., and achieve good compatibility, excellent transparency and gloss, and good adhesion performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

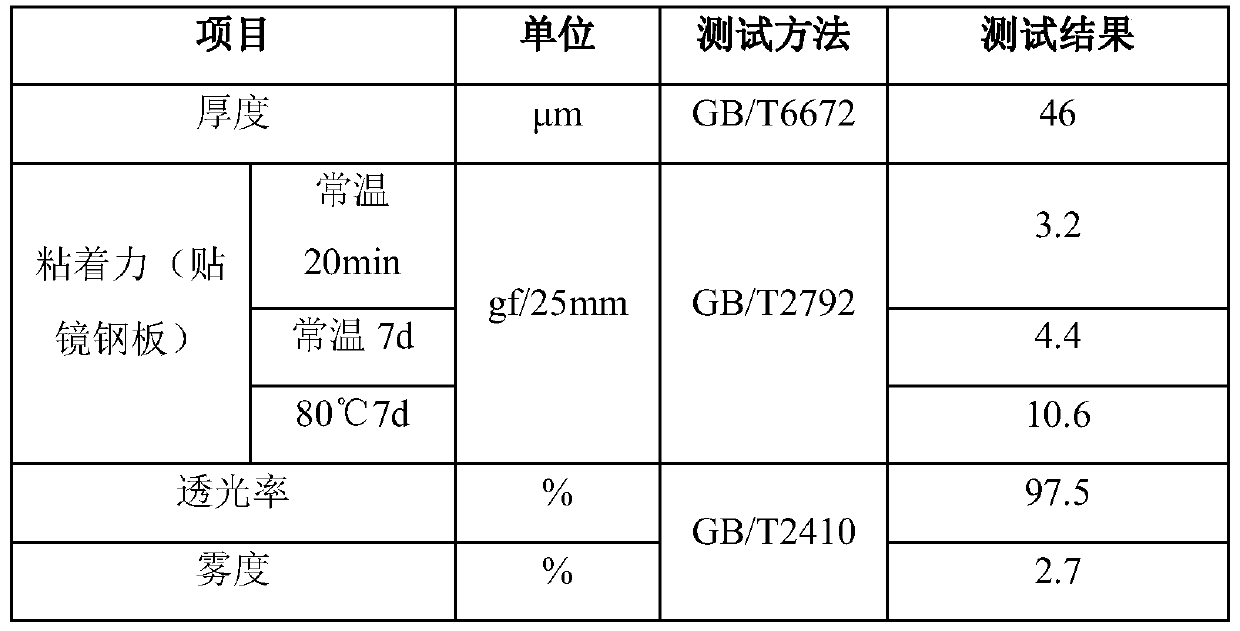

Embodiment 1

[0032] A PET protective film, comprising a PET base layer and an adhesive layer, the adhesive layer is made of metallocene polyethylene (MPE), wherein the mass fraction of metallocene polyethylene (MPE) is 100%, and the density is 0.89g / cm 3 , the melt index is 6.5g / 10min at 190°C and 2.16kg pressure, and the thickness of the adhesive layer is 8μm. Metallocene polyethylene (MPE) is purchased from Mitsui Chemicals Co., Ltd., Japan.

[0033] The PET base layer is a coated PET film with a longitudinal tensile strength of 227N / mm 2 , transverse tensile strength 235N / mm 2 ; Longitudinal elongation at break 95%, transverse elongation at break 97%; at 150°C / 15min, longitudinal heat shrinkage 1.2%, transverse heat shrinkage 0.2%; PET film density 1.35g / cm 3 , the thickness is 38μm, and the surface corona value is 40 dynes. From Yizheng Chemical Fiber Material Co., Ltd.

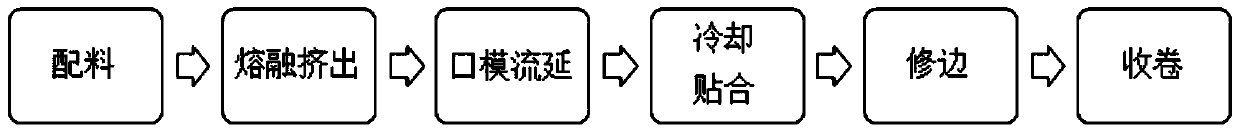

[0034] The preparation steps of above-mentioned protective film are:

[0035] After the above-mentioned component...

Embodiment 2

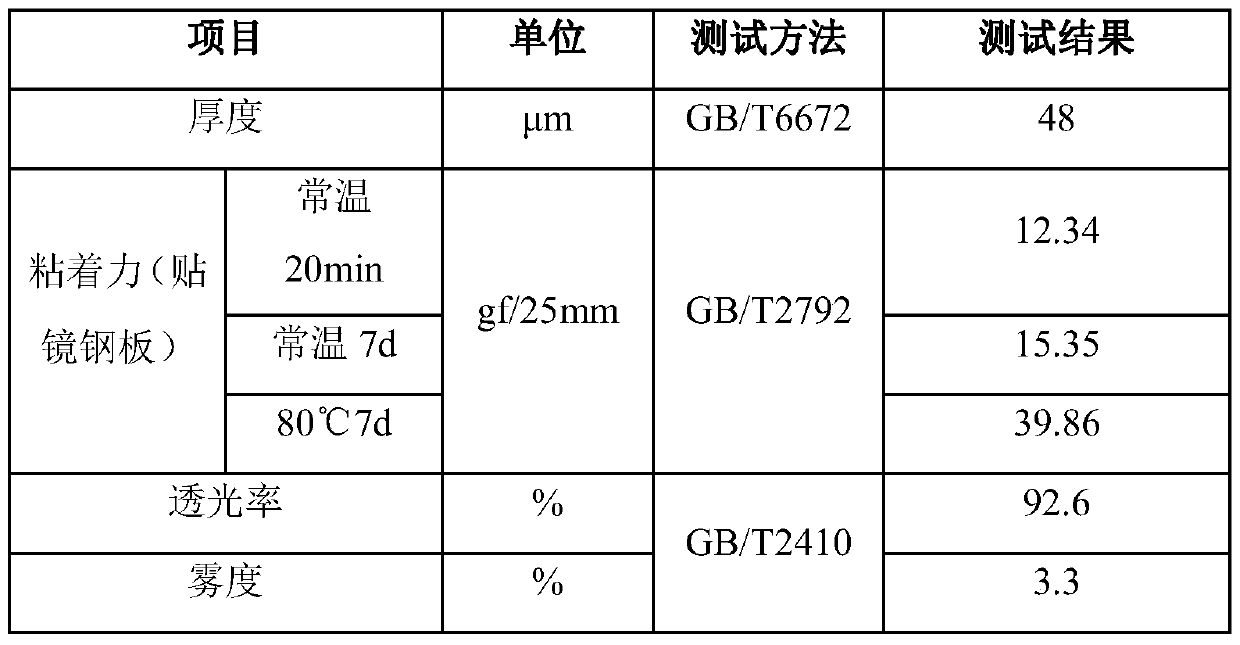

[0049] A PET protective film, comprising PET base layer and adhesive layer, adhesive layer adopts metallocene polyethylene (MPE) resin, POE elastomer, wherein, the mass fraction of metallocene polyethylene (MPE) resin is 95%, POE elasticity The mass fraction of body is 5%; the density of MPE is 0.90g / cm 3 The melt index at 190°C and 2.16kg pressure is 4.5g / 10min. The material is purchased from Mitsui Chemicals Co., Ltd., Japan. POE thermoplastic elastomer resin is a hydrogenated random copolymer of styrene polymer blocks and olefins , The material is purchased from Japan Asahi Kasei Co., Ltd., the molecular weight is 30000-80000, the molecular weight distribution index is between 1.5-2.5, and the density is 0.83g / cm 3 , under the conditions of 230°C and 2.16kg pressure, the melt index is 6.0g / 10min, and the thickness of the adhesive layer is 8μm.

[0050] The PET base layer is a coated PET film with a longitudinal tensile strength of 234N / mm 2 , transverse tensile strength 2...

Embodiment 3

[0057] A PET protective film, comprising a PET base layer and an adhesive layer, the adhesive layer is made of a metallocene polyethylene (MPE) resin and a POE elastomer, wherein the mass fraction of the metallocene polyethylene (MPE) resin is 70%, and the POE The mass fraction of elastomer is 30%, and the density of MPE is 0.90g / cm 3 , The melt index under the conditions of 190°C and 2.16kg pressure is 4.5g / 10min, the source of the material is Mitsui Chemicals Co., Ltd., Japan, POE thermoplastic elastomer resin is a hydrogenated random copolymer of styrene polymer block and olefin, the material Purchased from Japan Asahi Kasei Co., Ltd., the molecular weight is 30000-80000, the molecular weight distribution index is between 1.5 and 2.5, and the density is 0.88g / cm 3 , The melt index under the conditions of 230°C and 2.16kg pressure is 5.0g / 10min. The material is from Asahi Kasei Co., Ltd., Japan, and the thickness of the adhesive layer is 6 μm.

[0058] The PET base layer i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com