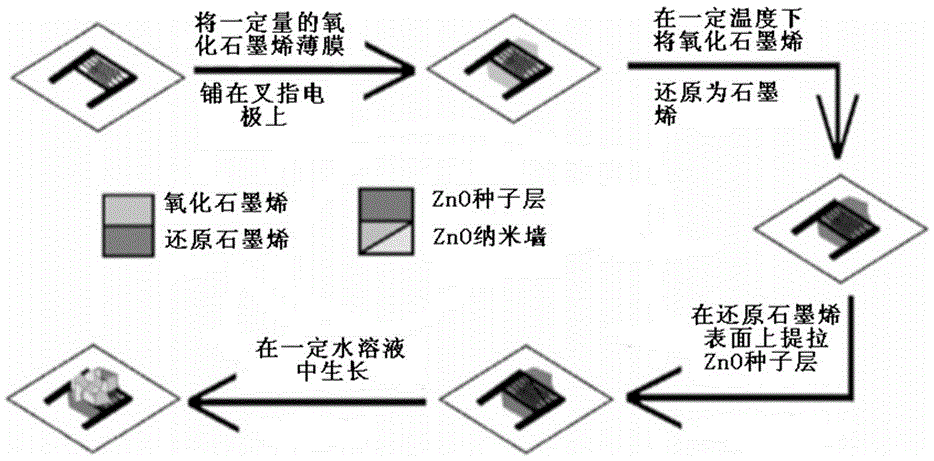

ZnO nano wall/RGO heterojunction gas-sensitive sensor and preparation method thereof

A gas-sensing sensor, nano-wall technology, applied in instruments, scientific instruments, measuring devices, etc., can solve the problems of high working temperature of the sensor, long response-recovery time, etc., to shorten the response-recovery time, improve the gas-sensing sensitivity, The effect of increasing the electron transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

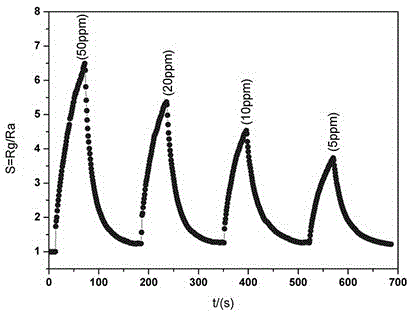

Embodiment 1

[0065] 1. Preparation of reduced graphene film

[0066] 1. Put the interdigital electrode in the mixed solution (deionized water: ammonia water: hydrogen peroxide = 5:1:1), perform ultrasonic cleaning, and then put it on a porcelain boat and wait for it to dry.

[0067] 2. Measure 1ml of graphene oxide solution, add deionized water to dilute to 1000ml, and sonicate for 1h.

[0068] 3. After ultrasonic uniformity, vacuum filter with a 0.45um filter membrane, wash with 1000ml of deionized water, and then use a 0.45um filter membrane for suction filtration.

[0069] 4. Cut the 0.45μm filter membrane to the same size as the interdigital electrode. Drop isopropanol on the interdigital electrode in advance, and then place the filter membrane on the interdigital electrode so that the filter membrane is close to the substrate, and then slowly add acetone dropwise until it is completely saturated.

[0070] 5. Pour 25mL of acetone into the petri dish, drain the air bubbles between the...

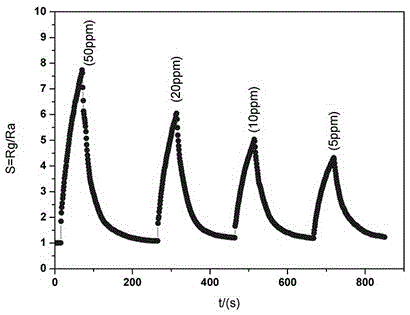

Embodiment 2

[0080] 1. Preparation of reduced graphene film

[0081] 1. Put the interdigital electrode in the mixed solution (deionized water: ammonia water: hydrogen peroxide = 5:1:1), perform ultrasonic cleaning, and then put it on a porcelain boat and wait for it to dry.

[0082] 2. Measure 2ml of graphene oxide solution, add deionized water to dilute to 1000ml, and sonicate for 1h.

[0083] 3. After ultrasonic uniformity, vacuum filter with a 0.45μm filter membrane, wash with 1000ml of deionized water, and then filter with a 0.45um filter membrane.

[0084] 4. Cut the 0.45um filter membrane to the same size as the interdigitated electrode. Drop isopropanol on the interdigital electrode in advance, and then place the filter membrane on the interdigital electrode so that the filter membrane is close to the substrate, and then slowly add acetone dropwise until it is completely saturated.

[0085] 5. Pour 25mL of acetone into the petri dish, drain the air bubbles between the filter membr...

Embodiment 3

[0095] 1. Preparation of reduced graphene film

[0096] 1. Put the interdigital electrode in the mixed solution (deionized water: ammonia water: hydrogen peroxide = 5:1:1), perform ultrasonic cleaning, and then put it on a porcelain boat and wait for it to dry.

[0097] 2. Measure 2ml of graphene oxide solution, add deionized water to dilute to 1000ml, and sonicate for 2h.

[0098] 3. After ultrasonication, vacuum filter with 0.45um filter membrane and wash with 1000ml deionized water.

[0099] 4. Cut the 0.45um filter membrane to the same size as the interdigitated electrode. Drop isopropanol on the interdigital electrode in advance, and then place the filter membrane on the interdigital electrode so that the filter membrane is close to the substrate, and then slowly add acetone dropwise until it is completely saturated.

[0100] 5. Pour 25mL of acetone into the petri dish, drain the air bubbles between the filter membrane and the Ag interdigitated electrode, put the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com