A kind of preparation method of direct methanol fuel cell anode catalyst

A methanol fuel cell and catalyst technology, applied in battery electrodes, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of high cost and difficult application of fuel cells, and achieve the promotion of electron transfer, high economic value, The effect of optimal electrocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

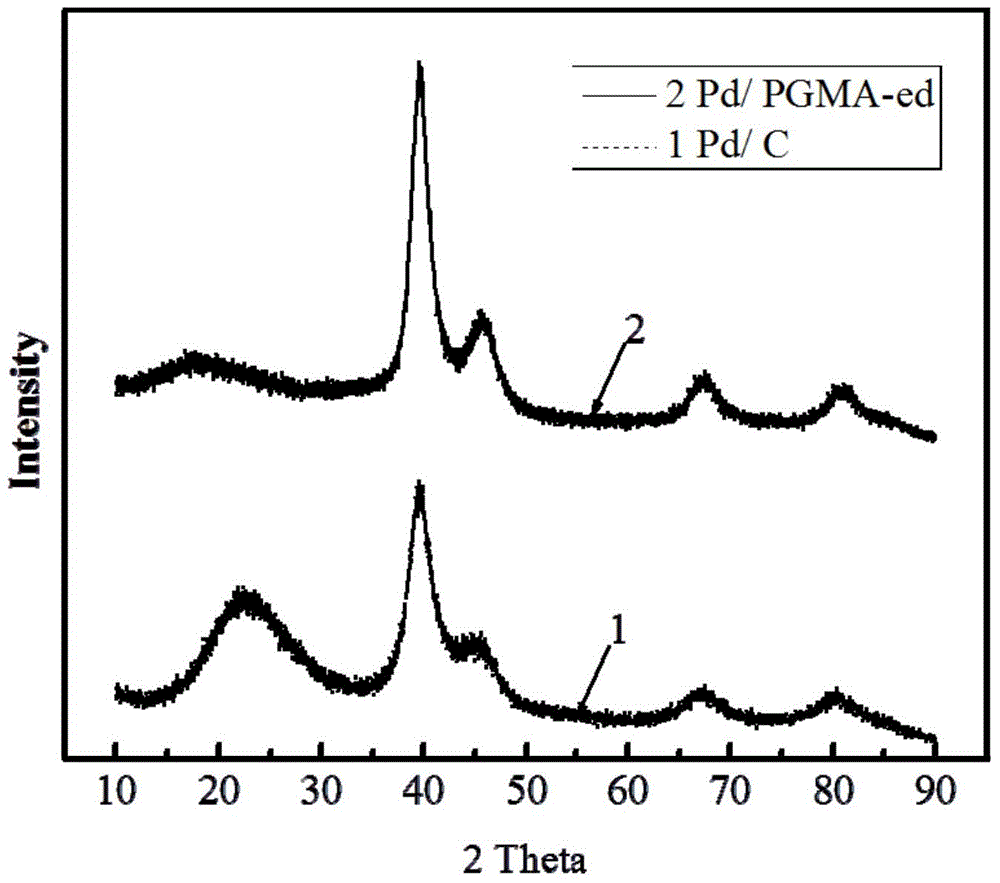

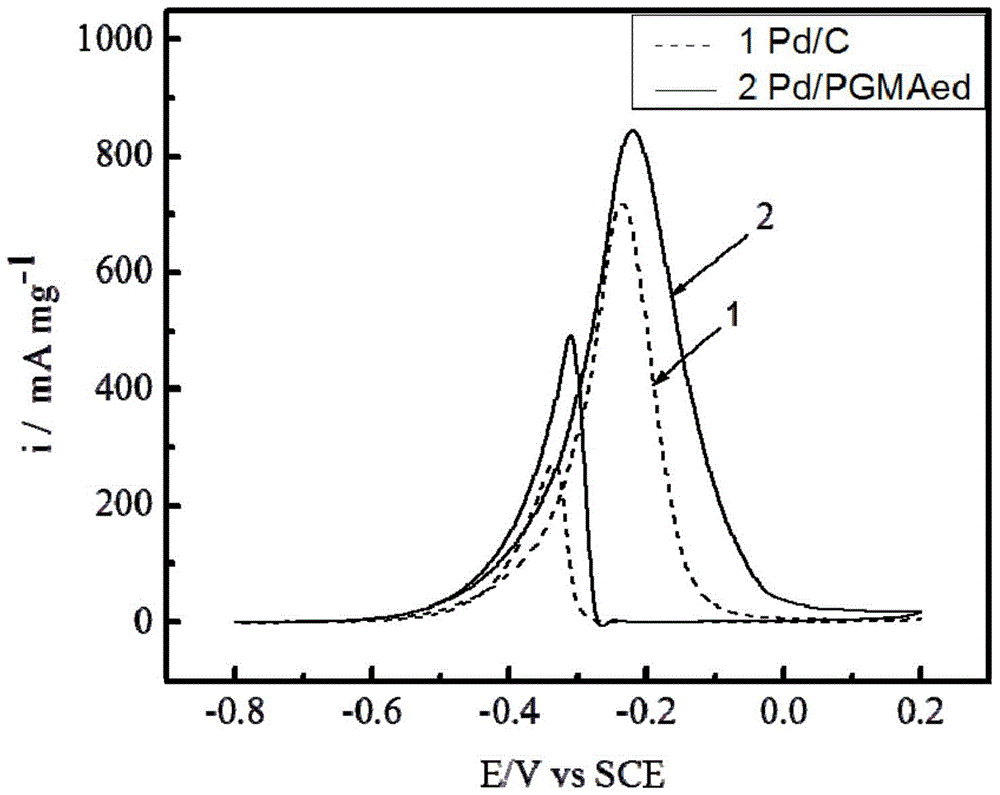

[0025] A method for preparing a direct methanol fuel cell anode catalyst carrier material, the direct methanol fuel cell anode catalyst carrier material Pd@PGMA-ed contains Pd, C, N, H and O elements.

[0026] The above-mentioned preparation method of the anode catalyst carrier material of the direct methanol fuel cell specifically comprises the following steps:

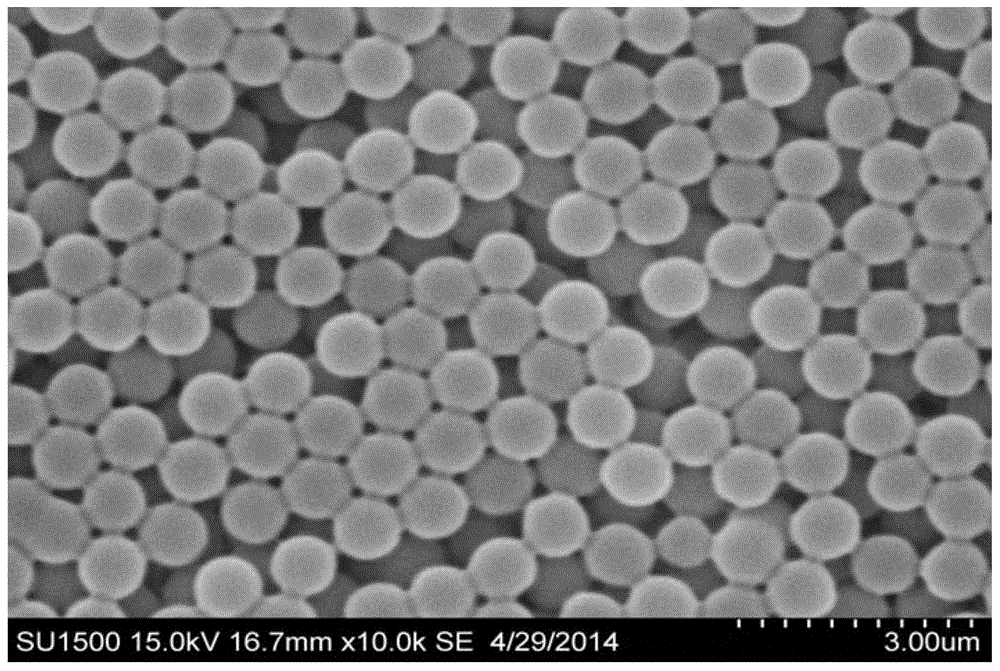

[0027] (1) Preparation of spherical carrier polymer PGMA

[0028] Add 10g of polymer monomer GMA to 10g of stabilizer PVP or EDTA, AIBN, react for 6-18 hours under nitrogen at 20-140°C, and obtain polymer PGMA after several times of centrifugal cleaning.

[0029] (2) Spherical carrier polymer PGMA epoxy ring opening

[0030] The polymer PGMA is added with 40ml of ethylenediamine and reacted at 20-140°C for 6-18 hours to obtain PGMA-ed.

[0031] (3) Spherical carrier polymer PGMA-ed loaded metal palladium

[0032] 40 mg of PGMA-ed was dissolved in deionized water, ultrasonicated for 30 minutes, 0.1 g of stabilizer ...

Embodiment 2

[0040] A method for preparing a direct methanol fuel cell anode catalyst carrier material, the direct methanol fuel cell anode catalyst carrier material Pd@PGMA-ed contains Pt, C, N, H and O elements.

[0041] (1) Preparation of spherical carrier polymer PGMA

[0042] 10g of polymer monomer GMA was added with 20g of stabilizer PVP, AIBN, reacted at 50°C under nitrogen for 8 hours, and the polymer PGMA was obtained after several times of centrifugal cleaning.

[0043] (2) Spherical carrier polymer PGMA epoxy ring opening

[0044] Add 20ml of ethylenediamine to polymer PGMA and react at 50°C for 15 hours to obtain PGMA-ed.

[0045] (3) Spherical carrier polymer PGMA-ed loaded metal palladium

[0046] 40mg of PGMA-ed was dissolved in deionized water, ultrasonicated for half an hour, no stabilizer was added, and K 2 PtCl 6 , continue to stir, adjust, and then slowly add 0.2g reducing agent KBH with a peristaltic pump 4 , kept stirring, and vacuum dried at 80°C for 15 hours to...

Embodiment 3

[0048] A method for preparing a direct methanol fuel cell anode catalyst support material, wherein the direct methanol fuel cell anode catalyst support material contains Pd, C, N, H and O elements, and its molecular formula is Pd@PGMA-ed.

[0049] (1) Preparation of spherical carrier polymer PGMA

[0050] The polymer monomer GMA was added with 10g of stabilizers PVP and AIBN, reacted for 14 hours under nitrogen, and the polymer PGMA was obtained after several times of centrifugal cleaning.

[0051] (2) Spherical carrier polymer PGMA epoxy ring opening

[0052] Polymer PGMA was added with 20ml of ethylenediamine and reacted at 40°C for 6 hours to obtain PGMA-ed.

[0053] (3) Spherical carrier polymer PGMA-ed loaded metal palladium

[0054] 40mg of PGMA-ed was dissolved in deionized water, sonicated for one hour, and the stabilizer hexadecyltrimethylammonium bromide was added, and the added K 2 PdCl 4 , keep stirring, adjust the pH=14, keep stirring, then slowly add sodium c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com