Optical pumping vector light beam solid laser

A solid-state laser and optical pumping technology, applied in the field of optics, can solve problems such as the inability to achieve longitudinal polarization state light field output, high manufacturing process requirements, complex laser process, etc., and achieve a simple structure, wide application range, and easy construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

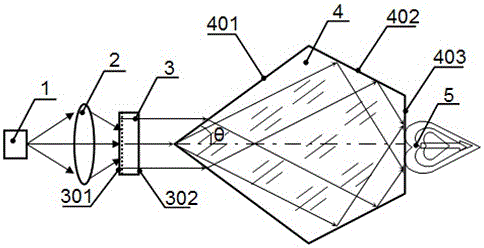

[0012] Such as figure 1 The schematic diagram of the structure of the optically pumped vector beam solid-state laser is shown. The optically pumped vector beam solid-state laser includes a pump source 1, a solid-state gain medium element 3, and a conical light field return element 4; the solid-state gain medium element 3 is a flat plate structure, and the solid-state gain The first optical working surface 301 of the dielectric element 3 is provided with an optical thin film, which has high reflectivity for laser wavelength light and high transmittance for pumping light wavelength light. On the second optical working surface 302 of the solid gain medium element 3 An optical thin film is provided, which has a high transmittance to the laser wavelength light and the pump light wavelength light; the solid gain medium element 3 and the conical light field return element 4 constitute a laser resonant cavity, and the second optical working surface of the solid gain medium element 3 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com