A pyrolysis gas high temperature electric dust collector with shock wave

An electrostatic precipitator and shock wave technology, which is applied in the field of pyrolysis gas high-temperature electrostatic precipitators, can solve the problems of poor cleaning effect, inability to achieve high-efficiency dedusting, and inability to meet long-term safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

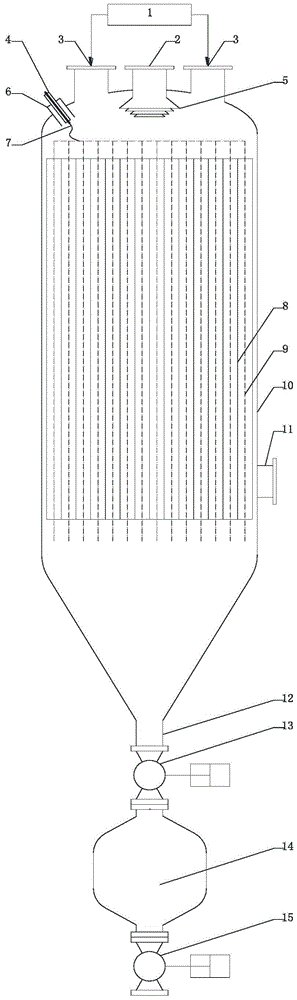

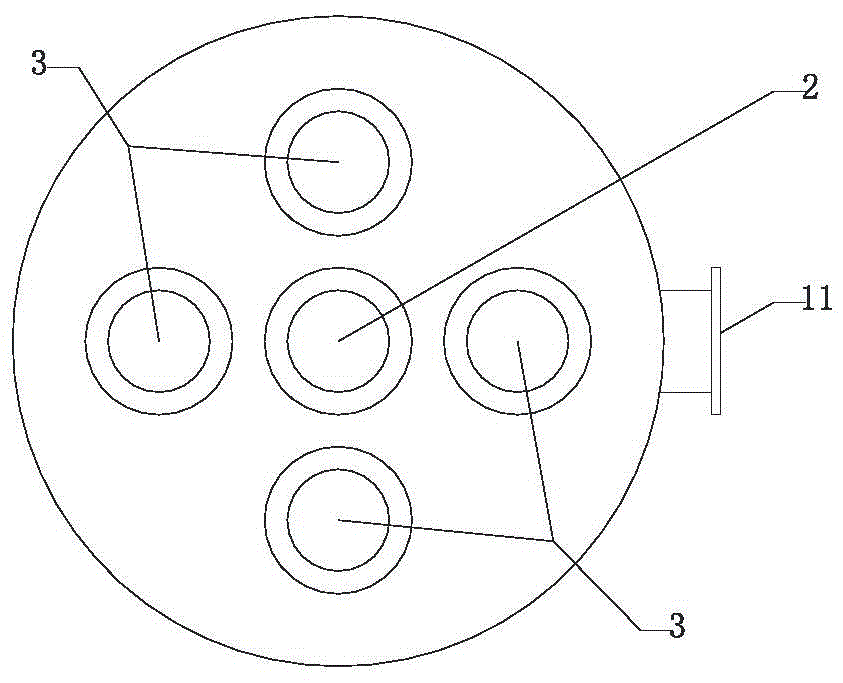

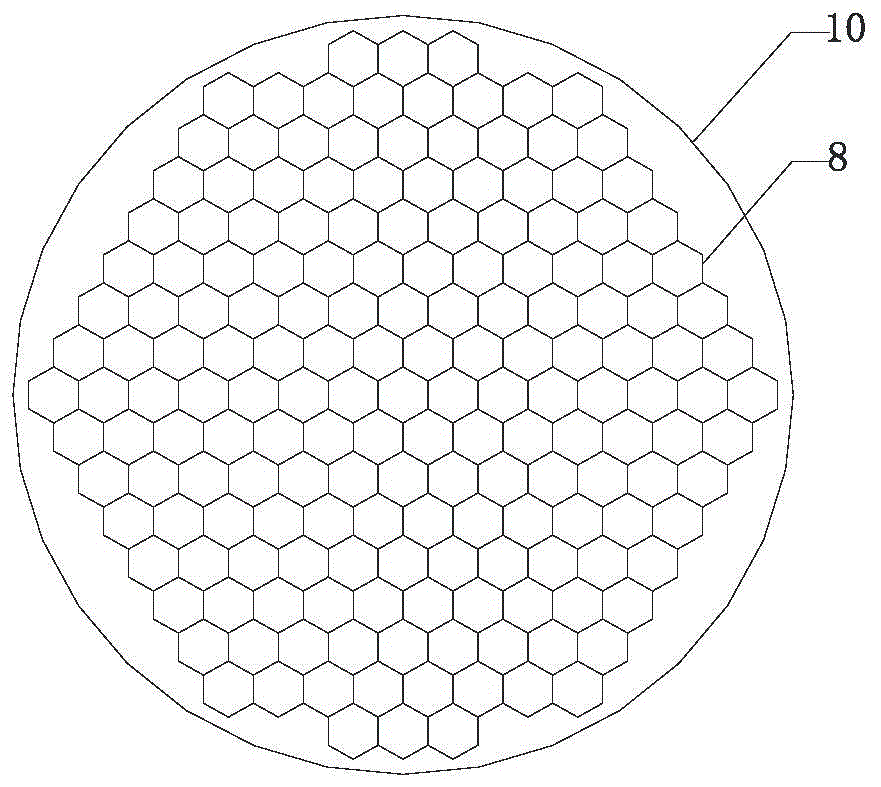

[0034]The 557°C pyrolysis gas from the cyclone separator of the known moving bed solid heat carrier pulverized coal pyrolysis device using Shenmu Hongliulin pulverized coal (long-flame coal) as raw material enters the shock wave through the pyrolysis gas inlet 2 Pyrolysis gas high-temperature electric dust removal device, the pyrolysis gas is evenly distributed between each anode plate 8 through the gas distributor 5 . The anode plate 8 is made of stainless steel with a thickness of 1 mm and is arranged in a hexagonal tube with a side length of 150 mm and a height of 10 m. The pyrolysis gas flows through the cathode rod 9 connected with a negative voltage and the anode plate 8 connected with a positive voltage at a flow rate of 1.2 m / s in the casing 10 of the high temperature electrostatic precipitator. A high-voltage electric field and a corona phenomenon are formed between the cathode rod 9 connected with a negative voltage and the anode plate 8 connected with a positive vol...

Embodiment 2

[0036] The 541°C pyrolysis gas from the cyclone separator of the known moving bed solid heat carrier pulverized coal pyrolysis device using Yunnan Xiaolongtan pulverized coal (lignite) as raw material enters the pyrolysis with shock wave through the pyrolysis gas inlet 2 Gas high-temperature electrostatic precipitator, the pyrolysis gas is evenly distributed between the anode plates 8 through the gas distributor 5 . The anode plate 8 is made of stainless steel with a thickness of 1.3mm and is arranged with hexagonal tubes with a side length of 250mm and a height of 12m. The pyrolysis gas flows through the cathode rod 9 connected with a negative voltage and the anode plate 8 connected with a positive voltage at a flow rate of 1.5 m / s in the casing 10 of the high temperature electrostatic precipitator. A high-voltage electric field and a corona phenomenon are formed between the cathode rod 9 connected with a negative voltage and the anode plate 8 connected with a positive voltag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com