A method for in-situ synthesis of gold nanorods/graphene oxide composites

A gold nanorod, in-situ synthesis technology, applied in the nano field, can solve problems such as complex preparation process, achieve the effects of simple operation, green and mild reaction conditions, and high loading capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

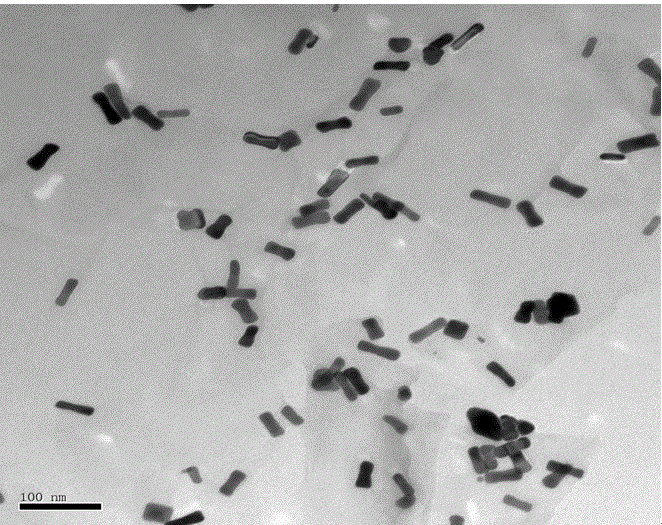

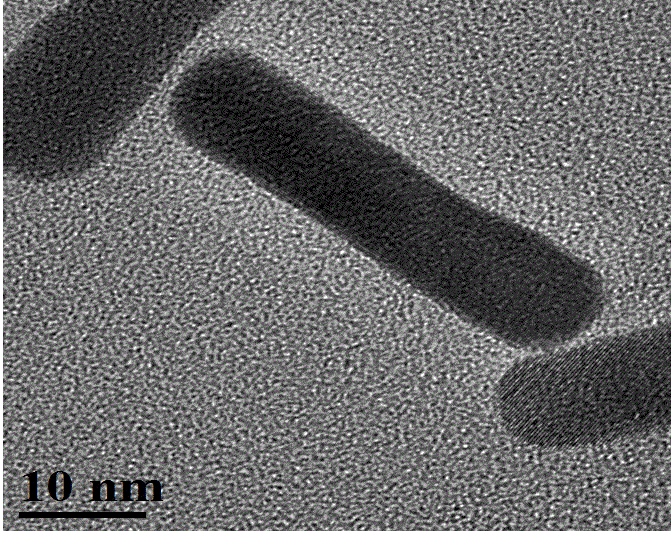

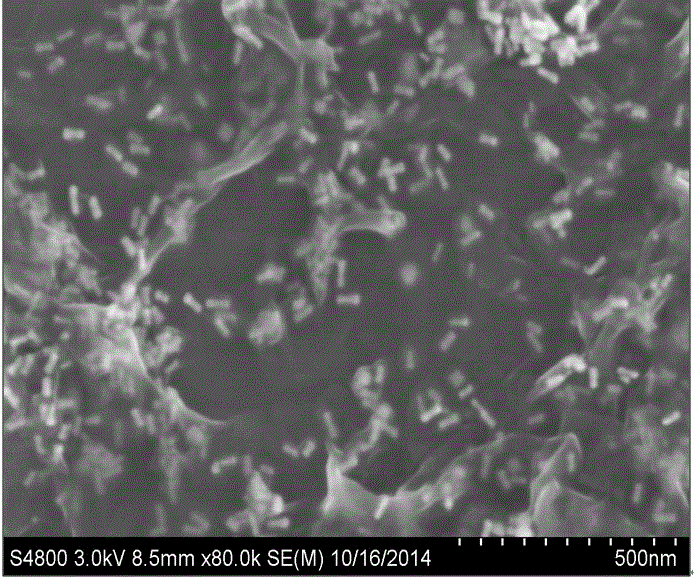

Image

Examples

Embodiment 1

[0022] (1) Take 5ml of cetyltrimethylammonium bromide solution (0.2M), 250μl of chloroauric acid solution (0.01M), 4.75ml of deionized water, 0.6ml of sodium borohydride solution (0.02M) and mix them After shaking vigorously for 30 seconds, it was left to stand at 30° C. for 7 hours.

[0023] (2) Mix 20 mg of ground graphene oxide with 60 ml of sodium polystyrene sulfonate solution dissolved in 0.5 g and sonicate (800 W, 20 minutes), and centrifuge at high speed for 3 times (11000 rpm, 15 minutes) after sonication, and finally the supernatant solution was redispersed in 50ml of water.

[0024] (3) Mix 50ml CTAB (0.1M) with the product obtained in step (2), and add 5ml chloroauric acid (0.01M), 0.8ml silver nitrate (0.01M), 550ul ascorbic acid (0.1M), and finally add 125ul step (1) The obtained product was added quickly and shaken for 30 seconds, and kept at a constant temperature of 27°C for 42 hours.

[0025] (4) The product obtained in step (3) was centrifuged at high spee...

Embodiment 2

[0028] (1) Take 5ml of cetyltrimethylammonium bromide solution (0.2M), 250μl of chloroauric acid solution (0.01M), 4.75ml of deionized water, 0.6ml of sodium borohydride solution (0.02M) and mix them After shaking vigorously for 30 seconds, it was left to stand at 30° C. for 7 hours.

[0029] (2) Mix 5mg of ground graphene oxide with 40ml of sodium polystyrene sulfonate solution dissolved in 1.2g and sonicate (500W, 20 minutes). solution was redispersed in 50ml of water.

[0030] (3) Mix 50ml CTAB (0.1M) with the product obtained in step (2), and add 5ml chloroauric acid (0.01M), 0.8ml silver nitrate (0.01M), 550μl ascorbic acid (0.1M), and finally add 125μl step (1) The obtained product was added quickly and shaken for 30 seconds, and kept at a constant temperature of 27°C for 40 hours.

[0031] (4) The product obtained in step (3) was centrifuged at high speed for 3 times (14000rpm, 20 minutes), and the centrifuged substrate was redispersed in water to obtain the final pro...

Embodiment 3

[0032] (1) Take 5ml of cetyltrimethylammonium bromide solution (0.2M), 250μl of chloroauric acid solution (0.01M), 4.75ml of deionized water, 0.6ml of sodium borohydride solution (0.02M) and mix them After shaking vigorously for 30 seconds, it was left to stand at 30° C. for 9 hours.

[0033] (2) Mix 15 mg of ground graphene oxide with 60 ml of sodium polystyrene sulfonate solution dissolved in 0.6 g and sonicate (700 W, 20 minutes), and centrifuge at high speed for 3 times after sonication (10,000 rpm, 15 minutes), and finally the supernatant solution was redispersed in 50ml of water.

[0034] (3) Mix 50ml CTAB (0.1M) with the product obtained in step (2), and add 5ml chloroauric acid (0.01M), 0.8ml silver nitrate (0.01M), 550μl ascorbic acid (0.1M), and finally add 125μl step (1) The obtained product was quickly added and shaken for 30 seconds, and kept at a constant temperature of 25°C for 48 hours.

[0035] (4) The product obtained in step (3) was centrifuged at high spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com