Arc weld bonding connecting system and method for dissimilar metals

A connection system and arc welding technology, applied in arc welding equipment, welding equipment, welding accessories, etc., can solve the problem of excessive corrosion of dissimilar metal welded joints, and achieve the purpose of suppressing the decline of mechanical properties of joints, easy to popularize and apply, and suitable for materials. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

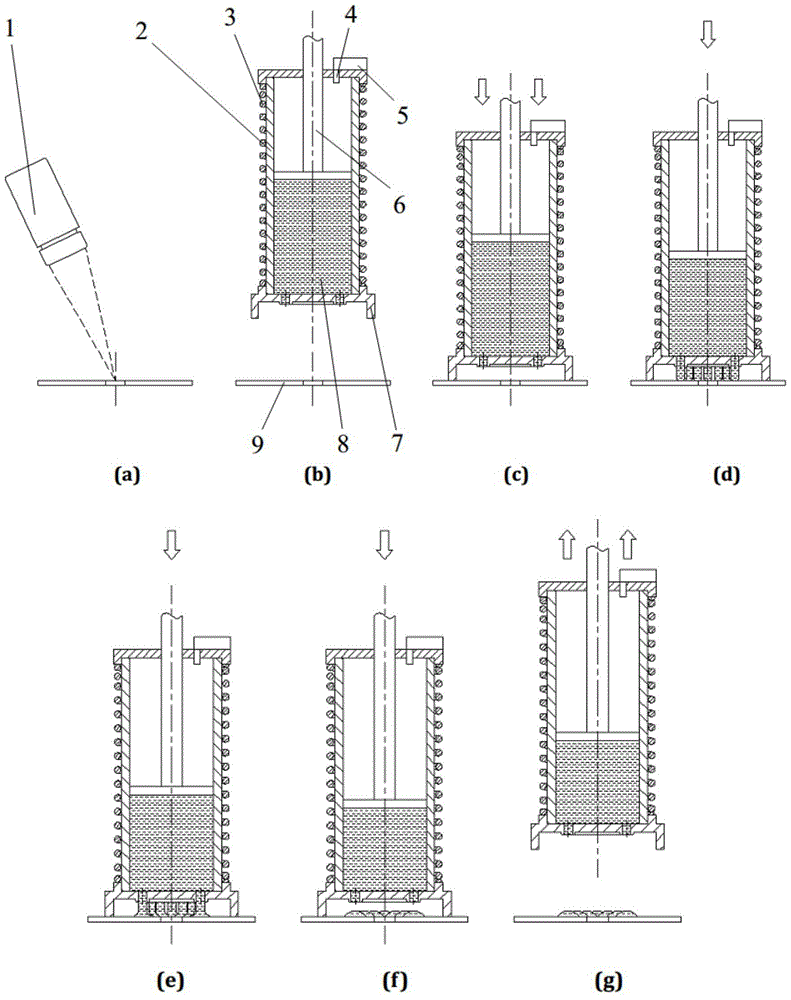

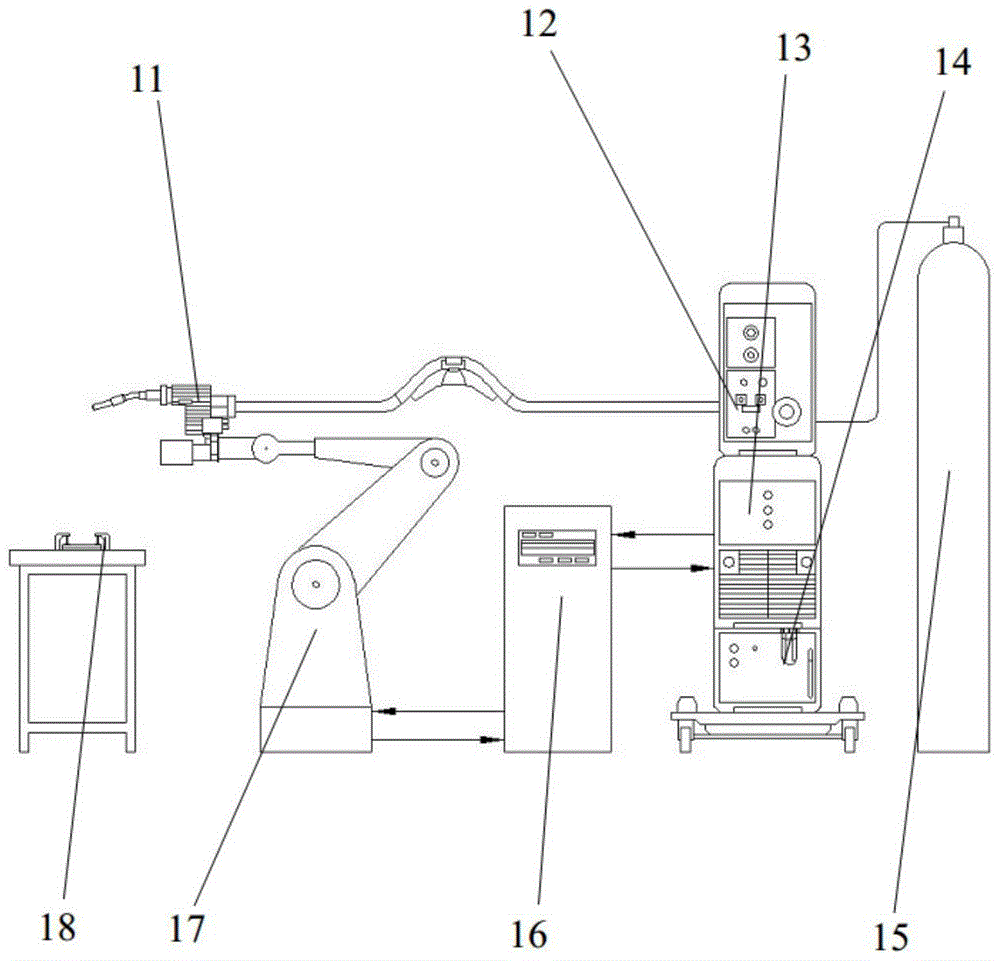

[0042] Such as Figure 1~3 As shown, this embodiment includes: an automatic gluing system composed of a gluing hole positioning device 1 and a gluing device, and an automatic arc welding system composed of a welding hole locating device 19, an arc welding system and a robot system, wherein: gluing The hole positioning device 1 is connected with the gluing device and transmits the coordinates of the center position of the gluing process hole. The robot system is connected with the arc welding system and transmits welding control instructions to realize the welding action. The robot system is connected with the welding hole positioning device 19 and receives the welding hole position information. .

[0043] The glue application device includes: a glue injection cylinder 2, a blank holder 7 and a thermocouple 4 respectively arranged at both ends of the glue injection cylinder, a heating coil 3 arranged outside the glue injection cylinder, and a piston movably arranged in the glue...

Embodiment 2

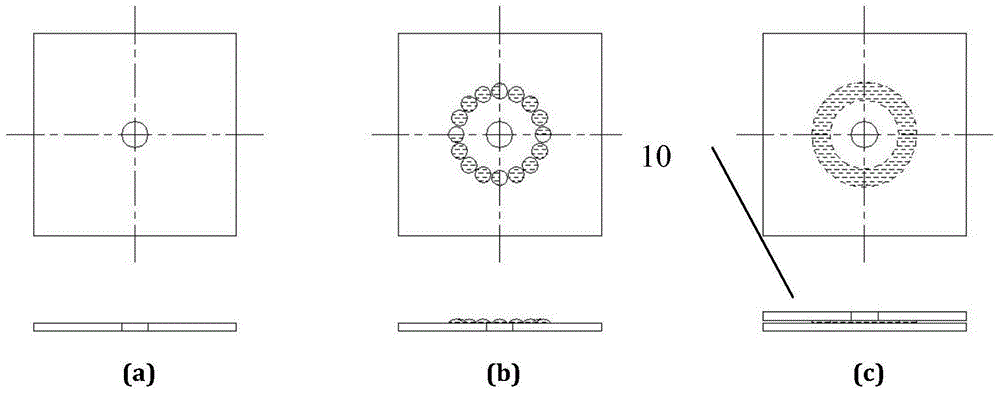

[0060] The metal plate 9 with holes in this embodiment is aluminum alloy 6022-T4, the lower galvanized steel plate 10 is electro-galvanized dual-phase high-strength steel DP780, the thickness of the plate is matched: 1mm+2mm, and the aluminum alloy plate 9 is mechanically polished to remove the surface Oxide layer, galvanized steel plate 10 uses acetone reagent to remove oil stains on the surface of the metal plate, adhesive 8 is epoxy resin two-component structural adhesive, welding wire 20 is made of A1Si3Mn, and its diameter is 1.2mm.

[0061] Process parameters: Welding current is 116A, voltage is 14V, wire feeding speed is 5.4m / min, welding gun movement speed is 32.6mm / s, arc length correction is 0%, welding wire withdrawal frequency is 70Hz, and argon is used as shielding gas. The flow rate is 20L / min.

[0062] The process of this embodiment is as figure 1 (a)~(g), figure 2 (a)~(c) and Figure 4 (a) ~ (d) as shown:

[0063] 1) Pre-punching a number of process holes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com