Calcium carbide furnace and method for preparing calcium carbide

A calcium carbide furnace and calcium carbide technology, applied in the field of metallurgy, can solve the problems of high cost, high power consumption, failure to meet the reaction requirements, etc., and achieve the effects of preventing the service life from being shortened, the heat distribution is uniform, and the production power consumption is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

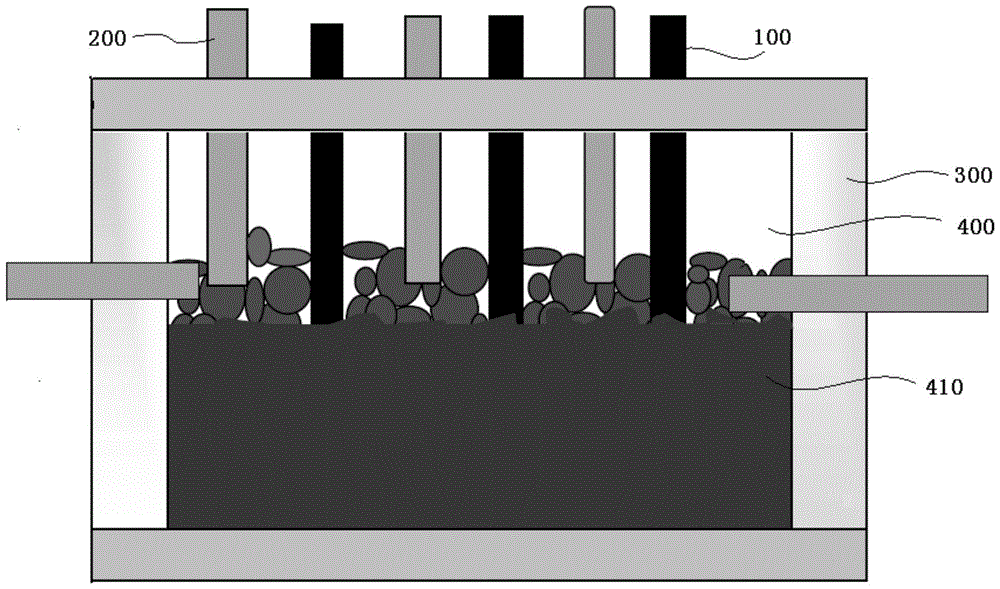

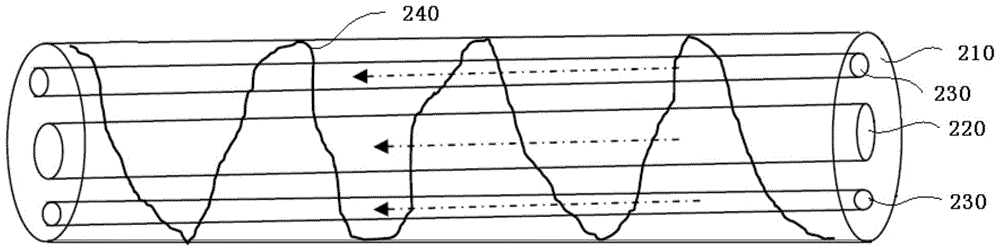

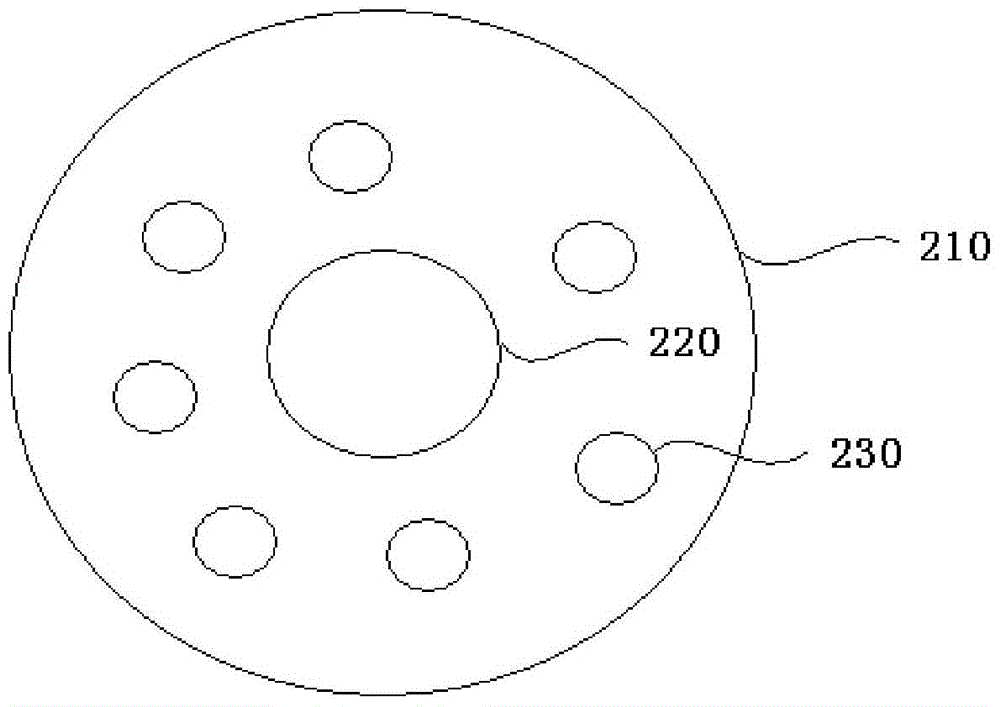

[0052] In this embodiment, the electrodes of the calcium carbide furnace are three-phase electrodes. The electrodes are inserted into the molten pool and do not touch the bottom of the furnace, so that electric arcs can be generated to heat the raw materials. Three spray guns are installed on the furnace cover of the calcium carbide furnace, one of which is located in the three-phase At the center of the electrode, the other two electrodes are symmetrically distributed outside the three-phase electrode, 2 / 3 radius away from the center of the horizontal interface of the calcium carbide furnace. The pipe is connected to the oxygen pressurization station through a high-pressure oxygen pipeline, the cooling water pipe is connected to the water pump, and the valve is set at the front of the spray gun. When spraying into the furnace, the pulverized coal pipeline, oxygen pipeline and valve are opened, and the pulverized coal / oxygen enters the spray gun. The pulverized coal is ejected ...

Embodiment 2

[0055] In this embodiment, the electrodes of the calcium carbide furnace are three-phase electrodes. The electrodes are inserted into the molten pool and do not touch the bottom of the furnace, so that electric arcs can be generated to heat the raw materials. Four spray guns are installed on the furnace cover of the calcium carbide furnace, and one of the spray guns is located in the three-phase At the center of the electrode, the other three electrodes are evenly distributed on the outside of the three-phase electrode, 5 / 6 radius away from the center of the horizontal interface of the calcium carbide furnace. The pipe is connected to the oxygen pressurization station through a high-pressure oxygen pipeline, the cooling water pipe is connected to the water pump, and the valve is set at the front of the spray gun. When spraying into the furnace, the pulverized coal pipeline, oxygen pipeline and valve are opened, and the pulverized coal / oxygen enters the spray gun. The pulverized...

Embodiment 3

[0058] In this embodiment, the electrodes of the calcium carbide furnace are three-phase electrodes. The electrodes are inserted into the molten pool and do not touch the bottom of the furnace, so that electric arcs can be generated to heat the raw materials. Four spray guns are installed on the furnace cover and side walls of the calcium carbide furnace, of which one The spray gun is located at the center of the three-phase electrode, and the other three electrodes are evenly distributed on the horizontal circumference of 1 / 2 of the side wall height. The pressure station is connected by a high-pressure oxygen pipeline, the cooling water pipe is connected with the water pump, and a valve is set at the front of the spray gun. The air is ejected from the spray gun, and the cooling water cools down the spray gun on the outer wall of the spray gun.

[0059] When the calcium carbide charge is loaded into the calcium carbide furnace, adjust the electrode and the spray gun so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com