Method for preparing nano TiO2 array on porous silicon substrate by adopting hydrothermal method

A technology of porous silicon and hydrothermal method, which is applied in the fields of nanotechnology, nanotechnology, and nanotechnology for materials and surface science, and achieves the effect of broad application prospects, excellent lattice unity, and simple preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

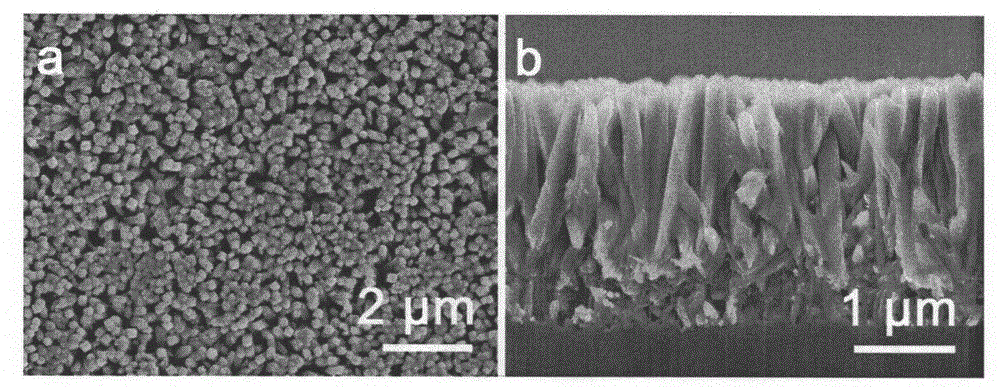

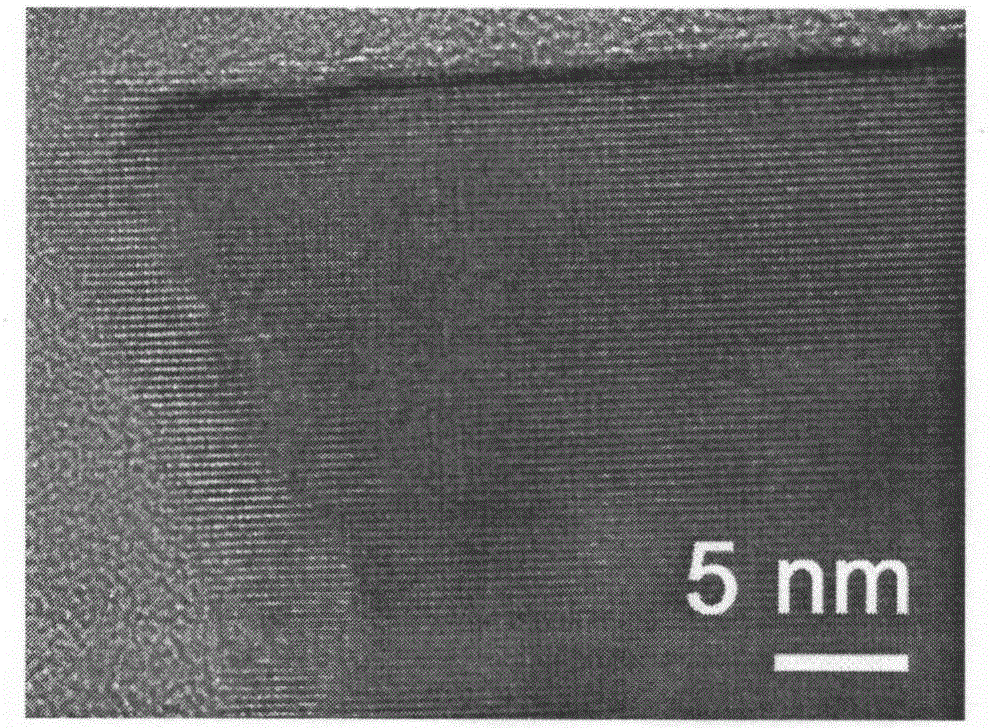

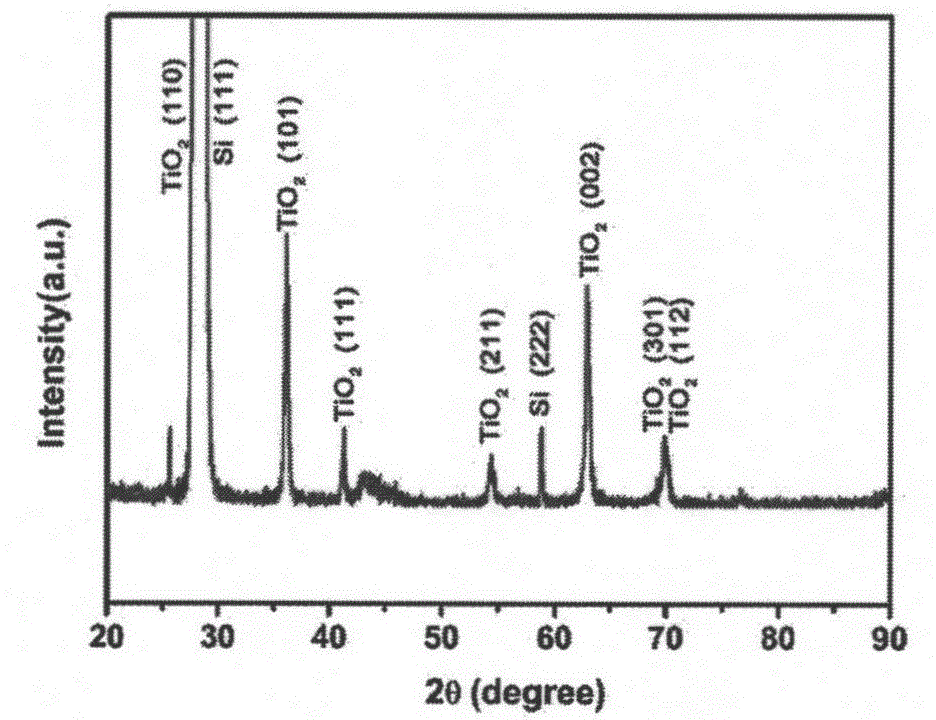

Image

Examples

Embodiment 1

[0032] A preparation of nano-TiO on porous silicon substrates by hydrothermal method 2 Array method, the specific steps are:

[0033] (1) Soak the porous silicon substrate in dilute hydrofluoric acid with a mass fraction of 6% for 10 minutes, wash it with deionized water, and then dry it in an inert gas;

[0034] (2) Coating a thin layer of titanium oxide on the above-mentioned porous silicon substrate by magnetron sputtering, the target material is a metal titanium target, the volume flow ratio of the reaction gas argon and oxygen is 3:1, the DC sputtering power is 30W, and the sputtering Shooting time 10 minutes;

[0035] (3) Put the above-mentioned porous silicon substrate coated with titanium oxide film into a muffle furnace, and calcinate at 450° C. for 2 hours;

[0036] (4) 0.4ml n-tetrabutyl titanate (C 16 h 36 o 4 Ti) stirring and dropping in 20ml of 19% hydrochloric acid solution with a mass fraction of 0.05ml / s to obtain a mixed solution;

[0037] (5) Put the a...

Embodiment 2

[0040] A preparation of nano-TiO on porous silicon substrates by hydrothermal method 2 Array method, the specific steps are:

[0041] (1) Soak the porous silicon substrate in dilute hydrofluoric acid with a mass fraction of 6% for 10 minutes, wash with deionized water, and dry in an inert gas;

[0042] (2) Coating a thin layer of titanium oxide on the above-mentioned porous silicon substrate by magnetron sputtering, the target material is a titanium oxide ceramic target, the reaction gas is argon, the radio frequency sputtering power is 30W, and the sputtering time is 10 minutes;

[0043] (3) Put the above-mentioned porous silicon substrate coated with titanium oxide film into a muffle furnace, and calcinate at 450° C. for 2 hours;

[0044] (4) 0.4ml n-tetrabutyl titanate (C 16 h 36 o 4 Ti) Stirring and dropping in 20ml of hydrochloric acid solution with a mass fraction of 19%, the dropping speed is 0.05ml / s to obtain a mixed solution;

[0045](5) Put the above-mentioned ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com