Hydrophilic polymer microsphere and simple preparing method thereof

A hydrophilic polymer and polymer technology, applied in the direction of adsorption of water/sewage treatment, etc., can solve the problems of harsh conditions, low yield, cumbersome steps, etc., and achieve uniform particle size, high yield, and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

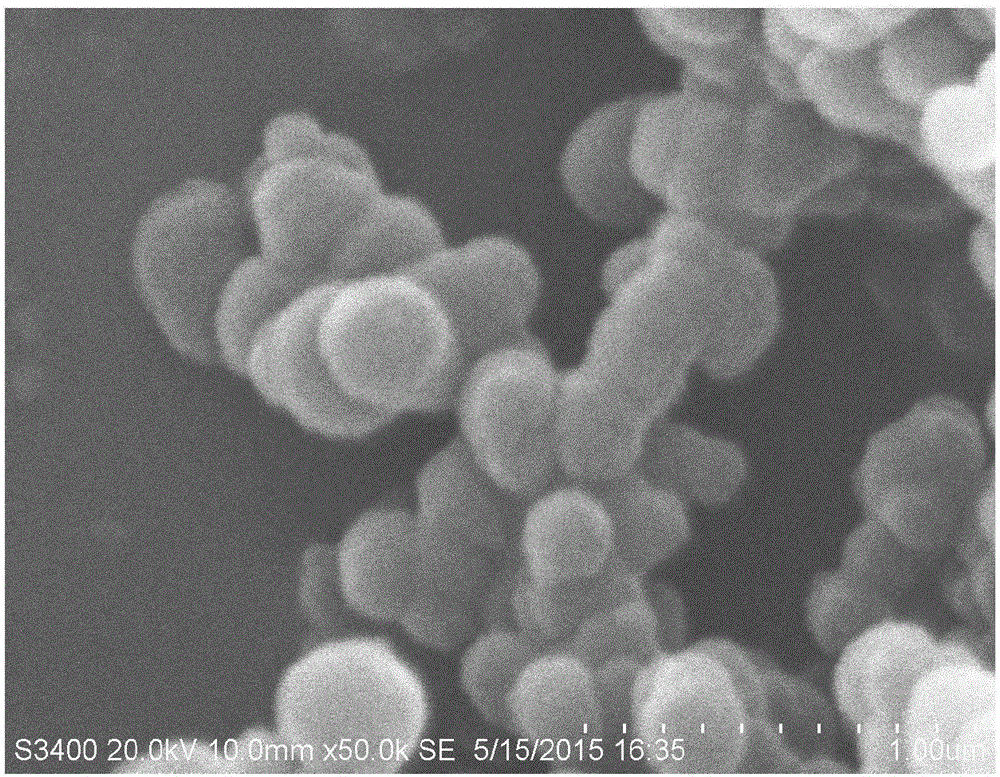

[0031] After mixing 10g of N-vinylpyrrolidone, 10g of divinylbenzene and 0.2g of azobisisobutyronitrile evenly, add it into a 500mL three-necked flask containing 100mL of anhydrous ethanol organic phase, control the stirring speed at 200rpm, and gradually Heating to 75° C., reacting for 3 hours, then filtering the obtained precipitate, washing with methanol three times, filtering, and washing with distilled water three times, and drying to recover polymer microspheres. The particle size of the obtained hydrophilic polymer microspheres is concentrated at 200nm, and the specific surface area is distributed at 23.8m 2 / g, the N content is 0.46%, the average pore size is 4.46nm, the scanning electron microscope picture is as figure 1 shown.

Embodiment 2

[0033] After mixing 25g of N-vinylpyrrolidone, 10g of divinylbenzene, 40g of toluene and 0.2g of azobisisobutyronitrile evenly, add them to a 500mL three-necked flask containing 100mL of anhydrous ethanol organic phase, control the stirring speed to 250rpm, and / 20min gradually heating up to 75°C, reacting for 4h, then filtering the obtained precipitate, washing with methanol for 5 times, filtering, and washing with distilled water for 3 times, and then drying to recover polymer microspheres. The particle size of the obtained hydrophilic polymer microspheres is concentrated at 400nm, and the specific surface area is distributed at 613m 2 / g, the N content is 1.4%, and the average pore diameter is 4.29nm. Under the condition of 35 DEG C, the adsorption capacity of the polymer spheres to the water-soluble tetracycline can reach 294.6 mg / g.

Embodiment 3

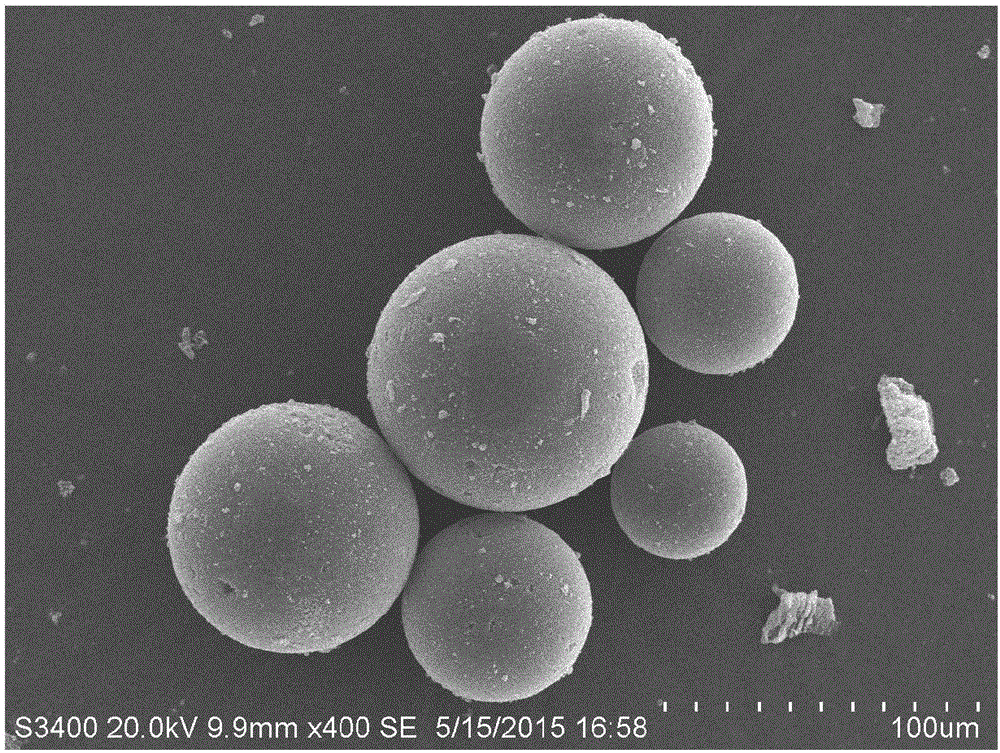

[0035] Mix 20g of N-vinylpyrrolidone, 10g of divinylbenzene and 0.2g of azobisisobutyronitrile evenly, add to 200mL of aqueous solution containing 13gNaCl and 1g of gelatin, control the stirring speed at 250rpm, and gradually heat at 5°C / 20min The temperature was raised to 85° C., reacted for 6 hours, and then the obtained precipitate was filtered, washed three times with methanol, filtered, washed three times with distilled water, and then dried to recover polymer microspheres. The particle size of the obtained hydrophilic polymer microspheres is concentrated at 60 μm, and the specific surface area is distributed at 520 m 2 / g, average pore diameter 6.69nm, scanning electron microscope picture as figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com