Neutron shielding material for spent fuel shipping flask

A technology for transport containers and shielding materials, applied in shielding, nuclear engineering, reactors, etc., can solve problems affecting shielding effects, low viscosity, etc., and achieve the effects of reducing raw material costs, ensuring uniformity, and facilitating casting and molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the examples, but not limited thereto.

[0030] Unless otherwise specified, the raw materials used in the examples are commercially available industrial supplies, which can be purchased through commercial channels.

[0031] The neutron shielding material of the present invention is composed of epoxy resin, curing agent, flame retardant and boron compound;

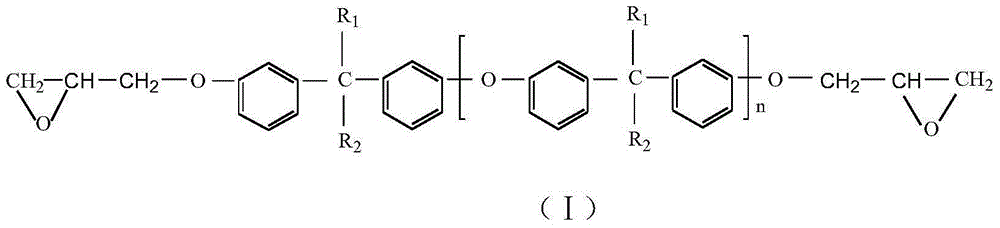

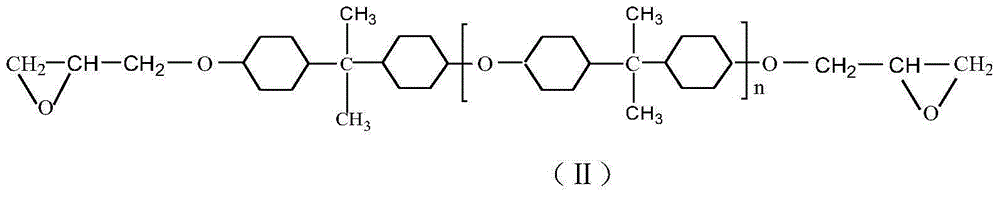

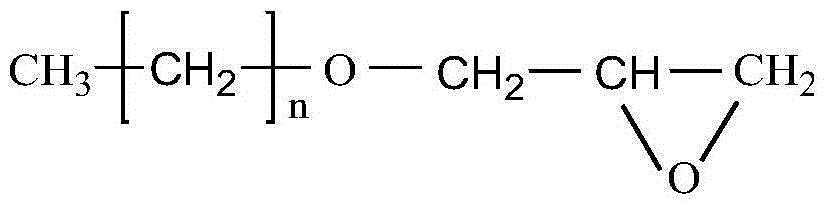

[0032] The epoxy resin is composed of 35-75 wt% of bisphenol A epoxy resin or bisphenol F epoxy resin, 5-40 wt% of hydrogenated epoxy resin, 20-40 wt% of reactive diluent, the sum of the above components is 100%;

[0033] The curing agent is a polyamine compound, and its consumption is calculated according to the equivalent ratio of amine hydrogen and epoxy group being 0.8 to 1.1;

[0034] The flame retardant is one or both of zinc borate, antimony oxide, magnesium hydroxide or aluminum hydroxide, and the weight ratio of its amount to the sum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com