Silicone rubber composite material used for seal rings and preparation method thereof

A technology of composite materials and silicone rubber, which is applied in the field of composite materials, can solve the problems of poor tensile strength and oil resistance, limit application occasions, etc., and achieve the effect of increasing vulcanization crosslinking density, improving oil resistance and excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

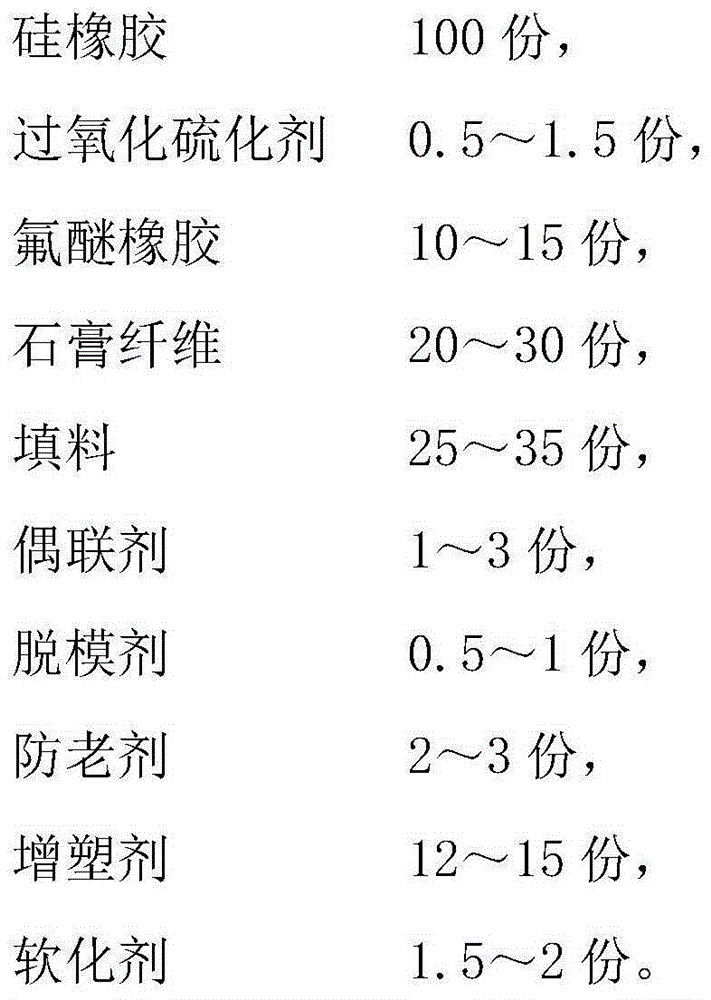

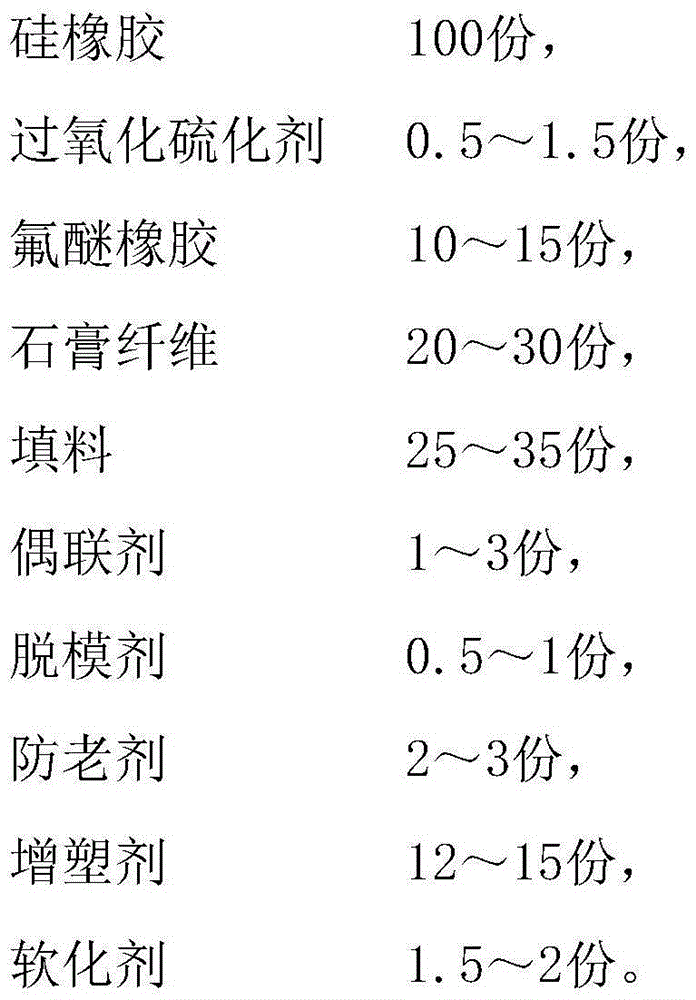

[0026] A silicone rubber composite material for sealing rings, made of the following components in parts by weight: 100 parts of methyl vinyl silicone rubber, 0.8 parts of DHBP, 14 parts of fluoroether rubber, 25 parts of gypsum fiber, mica Powder 25 parts, A-1511.5 parts, silicone oil 0.8 parts, antioxidant 4010NA 2.7 parts, simethicone oil 15 parts, triglyceride 1.6 parts.

[0027] The steps of its preparation method are as follows:

[0028] (1) dissolving the coupling agent in an ethanol solution with a mass fraction of 10% and mixing it uniformly to obtain a coupling agent solution with a mass fraction of 3%, cutting the gypsum fiber into a length of 1 mm, adding it to the coupling agent solution, and soaking for 10 After 10 minutes, move to a constant temperature water bath, heat at 90°C for 1 hour, take it out, wash it with deionized water three times, and place it in a drying oven at 95°C for 4 hours to obtain modified gypsum fibers;

[0029] (2) Add silicone rubber an...

Embodiment 2

[0031] A silicone rubber composite material for sealing rings, made of the following components in parts by weight: 100 parts of methyl vinyl silicone rubber, 1 part of DHBP, 12 parts of fluoroether rubber, 27 parts of gypsum fiber, and 30 parts of titanium dioxide parts, A-1511 parts, 0.6 parts of silicone oil, 2.5 parts of antioxidant 4010NA, 13 parts of simethicone oil, and 1.5 parts of triglyceride.

[0032] Its preparation method is the same as Example 1.

Embodiment 3

[0034] A silicone rubber composite material for sealing rings, made of the following components in parts by weight: 100 parts of methyl vinyl silicone rubber, 0.9 parts of DHBP, 15 parts of fluoroether rubber, 20 parts of gypsum fiber, mica 34 parts of powder, 2.5 parts of A-151, 0.7 parts of silicone oil, 2 parts of antioxidant 4010NA, 14.5 parts of simethicone, and 1.8 parts of triglyceride.

[0035] Its preparation method is the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com