A strain of Trichoderma hacinata that utilizes cellobiose to produce β-glucosidase

A technology of glucosidase and Trichoderma hamata, which is applied in the field of β-glucosidase preparation, can solve the problems of low activity, increasing the difficulty of suitable cellulase, and high demand for β-glucosidase, so as to reduce costs and solve The effect of feedback inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The preparation of embodiment 1 bacterial strain of the present invention

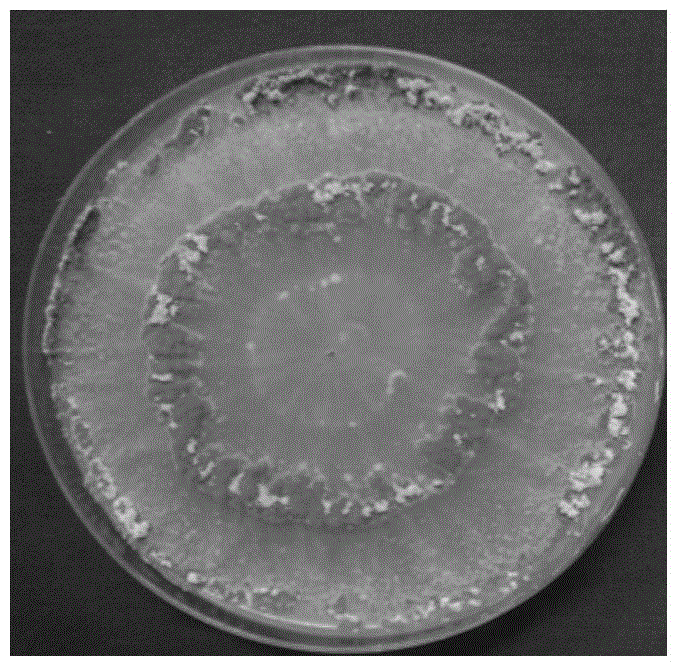

[0018] Take the soil collected in the paddy planting area of Jiangyong County, Yongzhou City, Hunan Province as the test material, take 20g of the dried test material soil sample, shake and cultivate at 160rpm / min for 30min, and make 10 -1 double dilution. Then, divide the 10 -1 Dilute the bacterial suspension to 10 times -2 、10 -3 、10 -4 、10 -5 、10 -6 、10 -7 、10 -8 . Spread the dilutions of each treatment evenly on the PDA medium and culture at 28°C for 3 days, pick a single colony for isolation and purification of single spores, and repeat this until the strains are purified, and the strain of the present invention can be obtained.

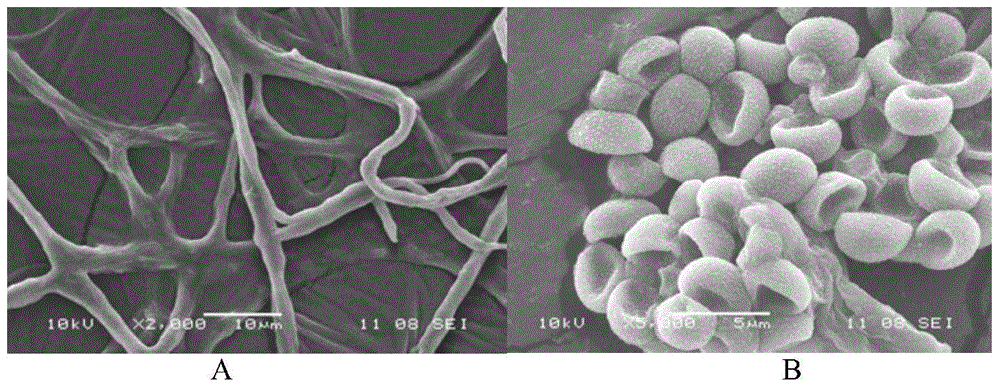

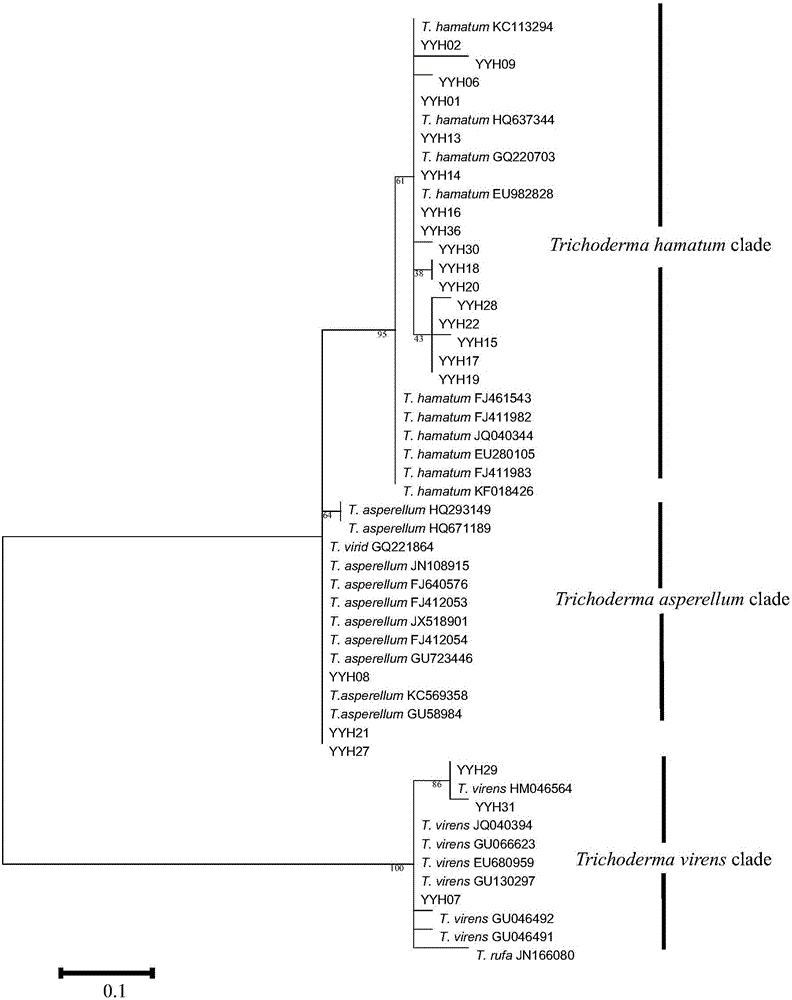

[0019] The total DNA of the strain of the present invention was extracted by SDS method, and PCR amplification was carried out by using primers ITS1 / ITS4. The total volume of the PCR reaction system is 25 μL: (ITS1 primer volume 1 μL, ITS4 primer volum...

Embodiment 2

[0021] The mensuration of embodiment 2β-glucosidase

[0022] Insert the bacterial strain YYH13 of the present invention into an Erlenmeyer flask of 100mL cellobiose basal medium with an inoculation amount of 1%-2%, and measure the β-glucoside in the fermentation broth after fermentation at 28°C and 180r / min for 48h Enzyme content.

[0023] Result: The glucose standard curve made is as follows Figure 4 As shown, the measured β-glucosidase activity reaches 457.9U / mL, which has a higher β-glucosidase activity.

[0024] The mensuration of β-glucosidase: with salicin as substrate, adopt the method of Chahal (1985), get the crude enzyme liquid of 0.5ml suitably diluted, add 1mL1% salicin solution (0.2M sodium acetate buffer, pH4 .8), react at a certain temperature for 30 min, and use the DNS method (Miller, 1959) to measure the amount of reducing sugar generated. The amount of enzyme needed to produce 1 μmol of reducing sugar per minute was defined as 1 activity unit (IU).

[0...

Embodiment 3

[0026] Example 3 Optimization of Cellobiose Fermentation Process Conditions

[0027] Taking cellobiose as the sole carbon source, and taking the optimum cellobiose concentration, fermentation temperature, fermentation time and rotation speed as the influencing factors, a four-factor and three-level L 9 (4 3 ) Orthogonal optimization test (Table 1), with the fermented liquid β-glucosidase content as an investigation index, determine the best conditions for fermentation. Orthogonal test results are shown in Table 2. According to the extreme difference analysis, the relationship affecting the fermentation performance of the bacterial strain of the present invention is respectively A>D>C>B, and the factors affecting the generation of β-glucosidase are fiber Disaccharide concentration, rotational speed, fermentation time, fermentation temperature, the best combination of each factor is A 2 B 1 C 2 D. 3 . Therefore, the optimum fermentation conditions are: cellobiose concentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com