Method for improving enzymolysis saccharifing yield of lignocellulose

A lignocellulosic enzyme and lignocellulose technology, applied in biofuels, fermentation, etc., can solve the problems of low fermentable sugar concentration, low enzymatic hydrolysis efficiency, high production cost, etc., achieve abundant sources, and increase enzymatic hydrolysis and saccharification yield , the effect of price regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

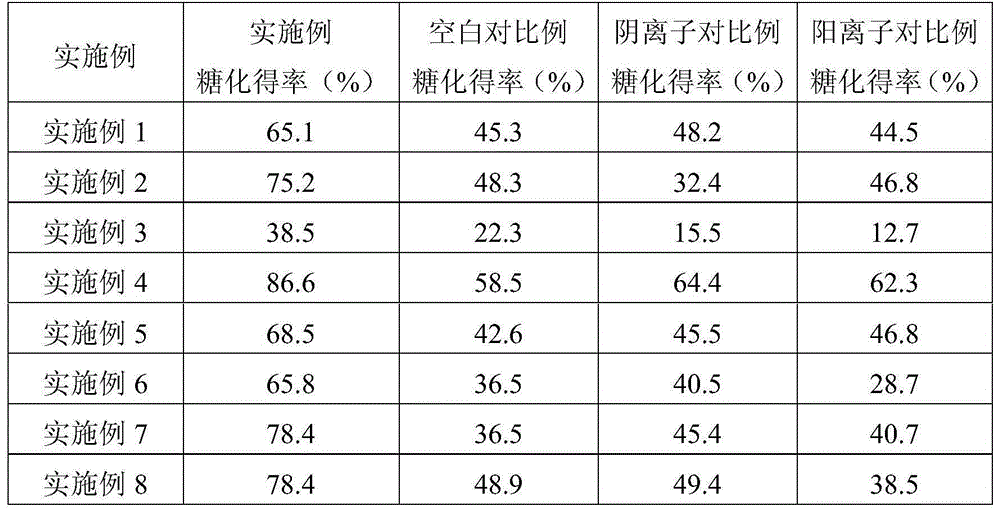

[0033] Get 100 parts by mass of PH101 microcrystalline cellulose, add it to 5000 parts by mass of pH 4.5, ionic strength is 25mmol / L of acetic acid-sodium acetate buffer solution, add 0.05 parts by mass of sodium lignosulfonate and 0.001 parts by mass of phenyl triphenyl Methyl ammonium bromide, then add 5 FPU / g cellulase based on the content of dextran in the cellulose, and react at a temperature of 50° C. for 72 hours. After the reaction, the cellulose hydrolyzate was obtained by solid-liquid separation, and the glucose content was measured by a biosensor analyzer. The statistical results are shown in Table 1.

Embodiment 2

[0035] Get 100 mass parts of eucalyptus pretreated by dilute acid method, join 2500 mass parts pH is 6.0, in the phosphate buffer solution that ionic strength is 100mmol / L, add 10 mass parts sodium lauryl sulfate and 1 mass part Decyltrimethylammonium bromide, and then add 5 FPU / g cellulase based on the glucan content in lignocellulose, and react at 40° C. for 72 hours. After the reaction, the lignocellulose hydrolyzate was obtained by solid-liquid separation, and the glucose content was measured by a biosensor analyzer. The statistical results are shown in Table 1.

Embodiment 3

[0037] Get 100 mass parts of dilute acid pretreated pine wood, join 2500 mass parts pH and be 5.0, ionic strength is in the acetic acid-sodium acetate buffer solution of 50mmol / L, add 100 mass parts sodium dodecylbenzenesulfonate and 100 parts by mass of dodecyltrimethylammonium chloride, and then adding 10 FPU / g of cellulase based on the dextran content in lignocellulose, and reacting at 50° C. for 72 hours. After the reaction, the lignocellulose hydrolyzate was obtained by solid-liquid separation, and the glucose content was measured by a biosensor analyzer. The statistical results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| ionic strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com