Alkali-resisting spinning refining agent and preparation method thereof

A refining agent and alkali-resistant technology, used in textiles, papermaking, fiber processing, etc., can solve the problems of biotoxicity, unstable quality and difficult degradation of additives, and achieve excellent alkali resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

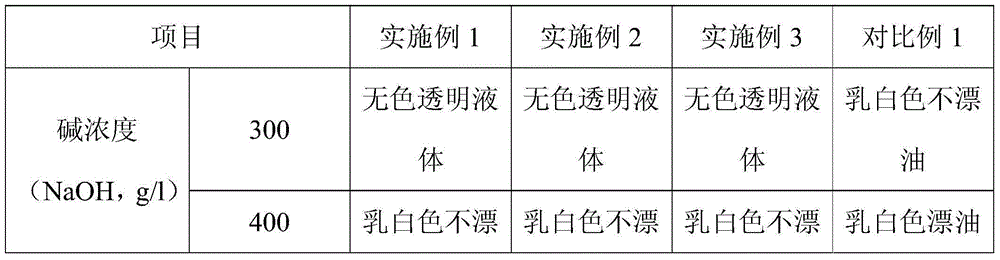

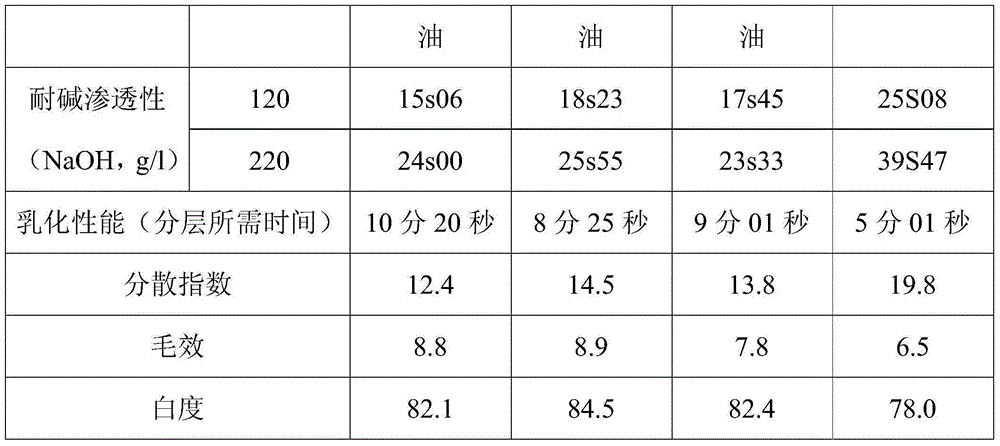

Examples

Embodiment 1

[0019] An alkali-resistant textile refining agent, consisting of the following components in weight percent: isomeric alcohol polyoxyethylene ether (ethoxylate addition number is 9) 12%, alkyl glucoside 08165%, dodecylbenzenesulfonate sodium phosphate 30%, ethylene glycol monobutyl ether 5%, ethyl acetate 8%, ethylenediaminetetraacetic acid 0.5%, polyoxypropyl polyoxyethyl glyceryl ether 1.5% and water 38%.

[0020] The refining agent is prepared according to the preparation method of the present invention.

Embodiment 2

[0022] An alkali-resistant textile refining agent, composed of the following components in weight percent: isomeric alcohol polyoxyethylene ether (ethoxylate addition number is 9) 15%, alkyl glucoside 081610%, dodecylbenzenesulfonate sodium nitrate 20%, ethylene glycol monobutyl ether 8%, ethyl acetate 5%, ethylenediaminetetraacetic acid 0.2%, polyoxypropyl polyoxyethyl glyceryl ether 2% and water 39.8%.

[0023] The refining agent is prepared according to the preparation method of the present invention.

Embodiment 3

[0025] An alkali-resistant textile refining agent, consisting of the following components in weight percent: isomeric alcohol polyoxyethylene ether (ethoxylate addition number is 9) 10%, alkyl glucoside 0816.2%, dodecylbenzenesulfonate sodium phosphate 35%, ethylene glycol monobutyl ether 7%, ethyl acetate 10%, ethylenediaminetetraacetic acid 0.8%, polyoxypropyl polyoxyethyl glyceryl ether 1% and water 30%.

[0026] The refining agent is prepared according to the preparation method of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com