Composite electrode material for supercapacitor, preparation method of composite electrode material and supercapacitor

A technology for supercapacitors and composite electrodes, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve the problems of thin-layer structure agglomeration, stacking, reducing the effective specific surface area of graphene, and unstable two-dimensional structure crystals. , to achieve the effect of improving specific capacitance and cycle stability, avoiding insufficient contact and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The composite electrode material for a supercapacitor provided by the present invention, its preparation method, and a supercapacitor using the electrode material will be further described in detail below in conjunction with the accompanying drawings and specific examples.

[0018] Embodiments of the present invention provide a method for preparing a composite electrode material for a supercapacitor, comprising the following steps:

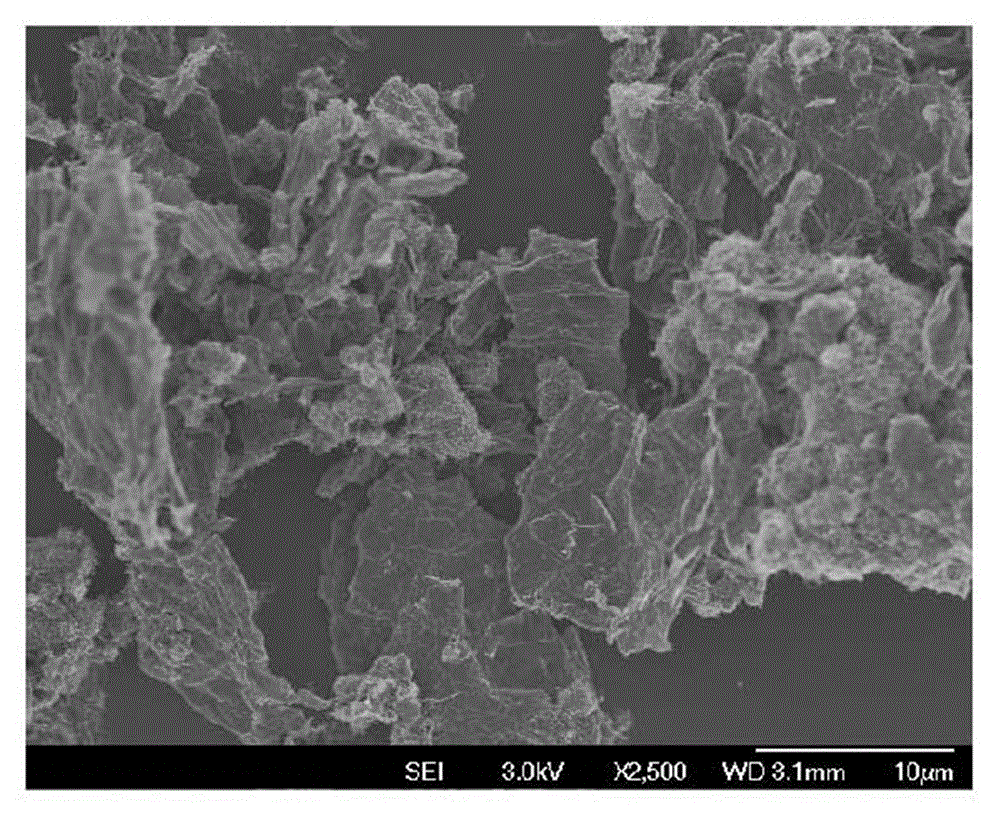

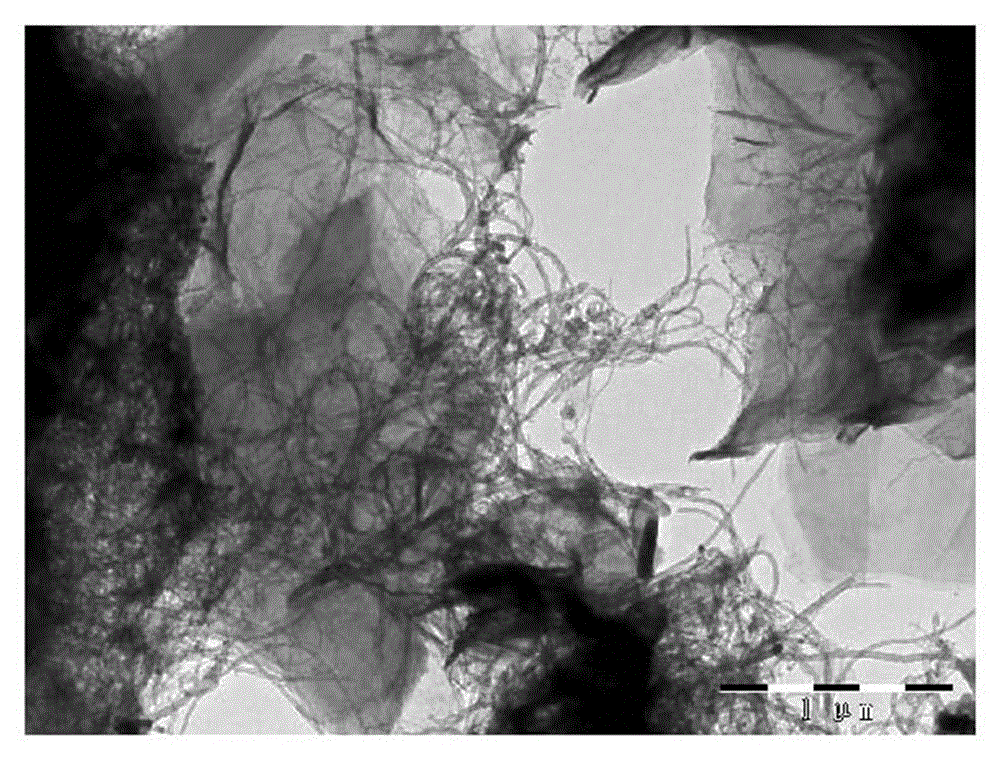

[0019] 1) Preparation of three-dimensional graphene oxide-hydroxylated carbon nanotube airgel, including: 1-1) preparation of graphene oxide-hydroxylated carbon nanotube dispersion; 1-2) hydrothermal reaction to obtain three-dimensional graphene oxide- Hydroxylated carbon nanotube composite gel; and 1-3) freeze-drying the composite gel to obtain a three-dimensional graphene oxide-hydroxylated carbon nanotube aerogel;

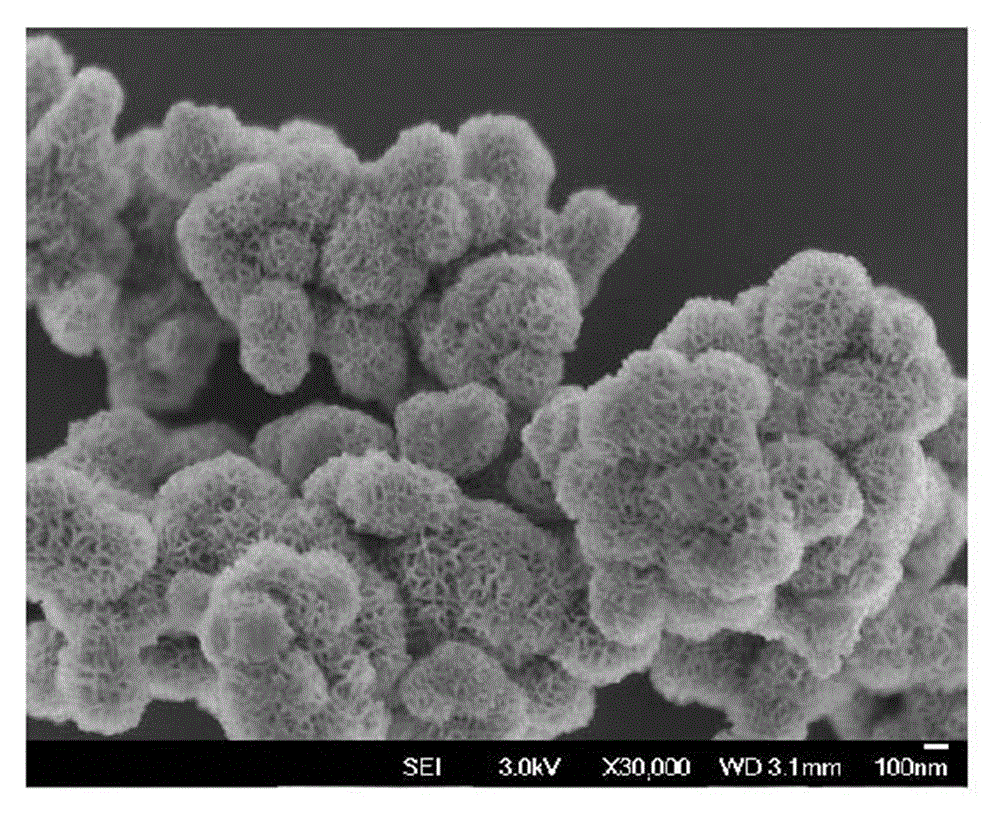

[0020] 2) uniformly dispersing carbon black (carbonblack) particles in a potassium permanganate solution to obtain a carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com