Tabletting and molding method for nano sticky powder

A molding method and powder technology, which is applied in the field of tablet molding of nano-viscous powder, can solve the problems that the release agent cannot meet the needs of tablet molding, related process obstacles, and difficulty in demoulding, so as to promote adhesion, Improve the electrical performance and increase the effect of the interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

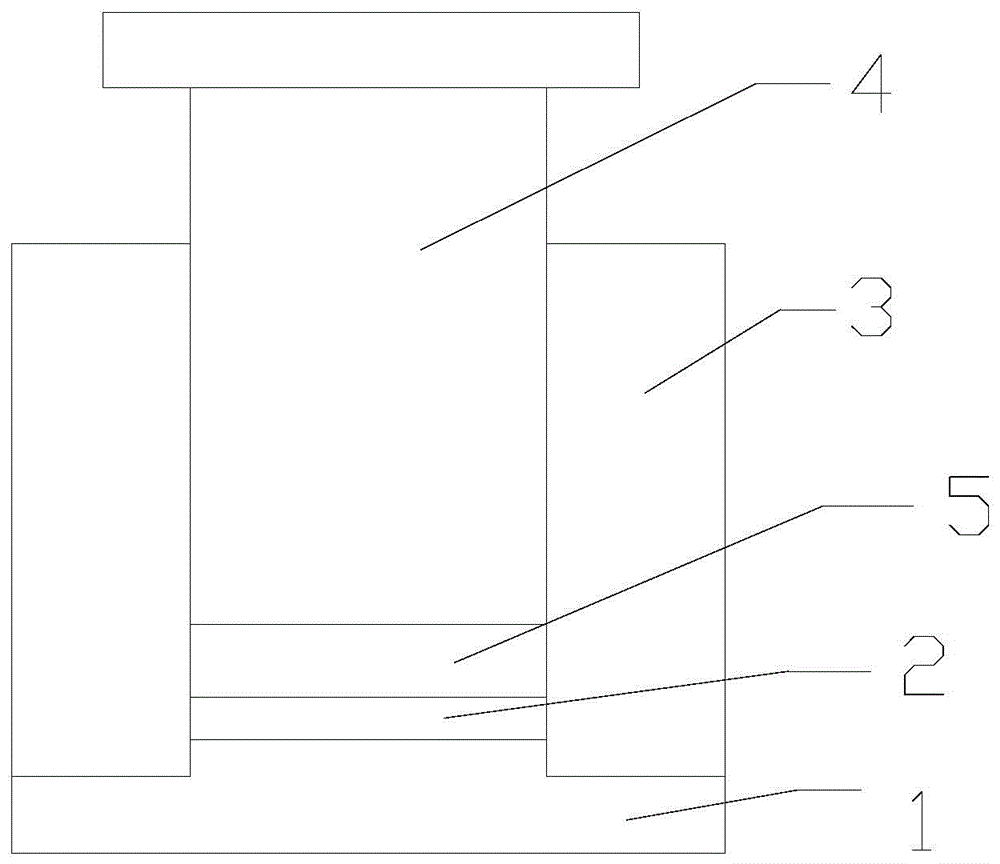

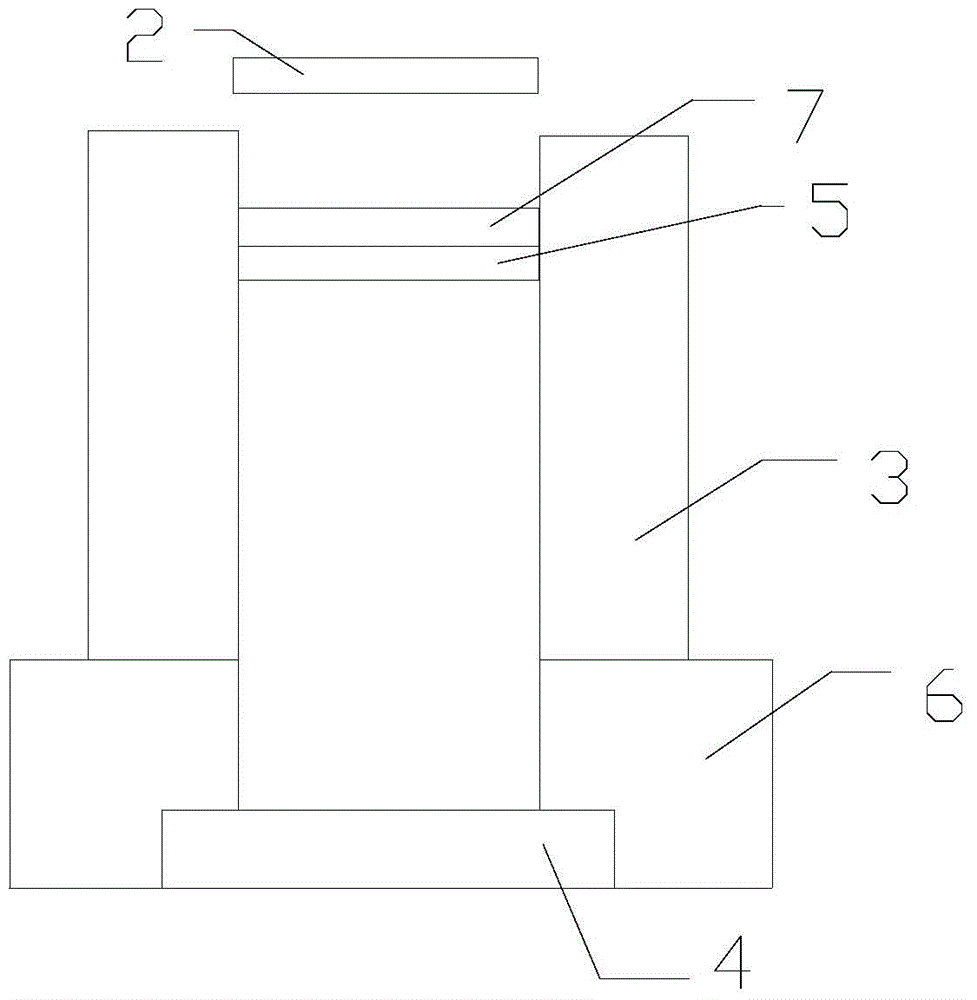

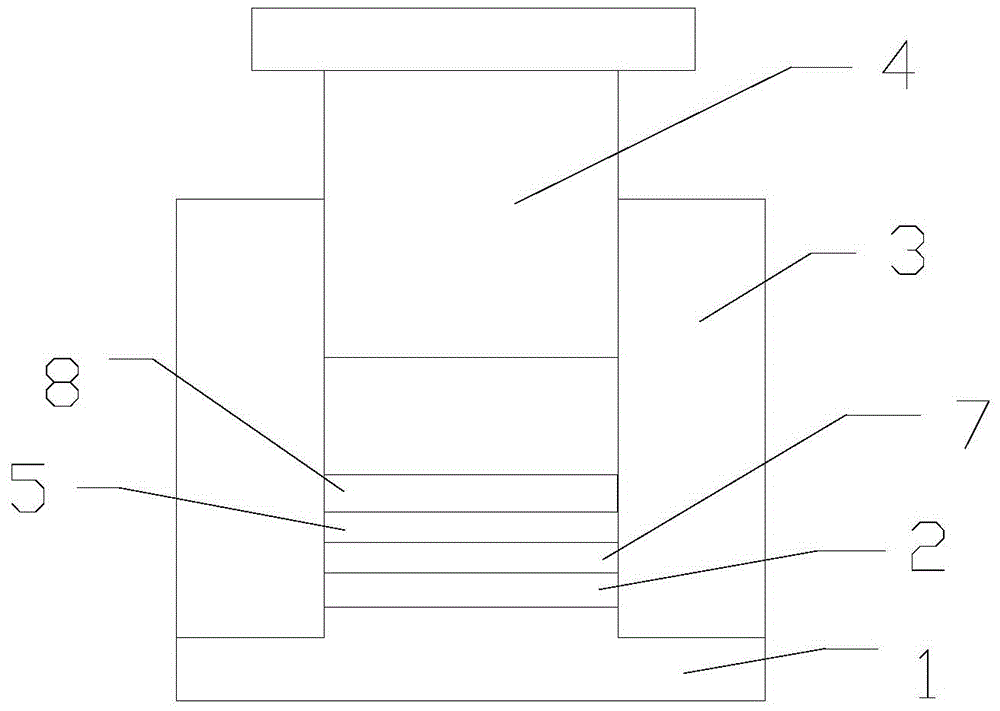

[0028] Step 1. Combine Figure 1 to Figure 3 , according to 0.1~0.6g / cm 2 The nano-viscous gadolinium-doped cerium oxide (GDC) powder 5 is weighed and evenly loaded into the mold, and lightly pressed manually so that the GDC powder 5 has an appropriate bulk density. At this time, the pressure should be moderate. If the pressure is too high, the powder will be easily bonded to the mold. If the pressure is too low, the powder will not be basically fixed. In the subsequent steps, the GDC powder 5 will easily mix with the barrier layer, resulting in difficulty in demoulding.

[0029] Step 2. Invert the mold, and place a supporting body 6 under the mould. The supporting body is an annular supporting body. The height of the support body 6 is equivalent to the vertical distance between the top of the mold pressing shaft 4 and the upper edge of the mold cavity 3 . The function of the support body 6 is to prevent the large displacement of the uncompressed green body, take out the upp...

Embodiment 2

[0033] Step 1. Put 0.1~0.6g / cm in the mold 2 NiO, GDC and pore-forming agent anode mixed powder, the mass ratio of the three is 5:5:1, gently flattened, so that the powder has an appropriate bulk density. At this time, the pressure should be moderate. If the pressure is too high, the powder will not be well combined with the electrolyte that will be co-pressed with it. If the pressure is too low, the powder will not be basically fixed.

[0034] Step 2. Invert the mold, place a ring-shaped support under the mold, take out the mold gasket above, and use a 80-600 mesh screen to filter the weighed nano GDC viscous powder (0.02-0.2g / cm 2 ) spread evenly over the anode body, and then put into the mold gasket and press it manually again.

[0035] Step 3. Take out the mold gasket, continue to spread an appropriate amount of barrier layer powder on the viscous GDC powder with a sieve of 80-600 mesh, with a thickness of 2-200 μm, and then put the mold gasket and mold base again .

[...

Embodiment 3

[0039] This embodiment is implemented on the basis of embodiment 1, and the difference from embodiment 1 is only that: the barrier layer powder in embodiment 1 is changed into a weighing paper sheet with the same shape and area as the mold gasket, and the rest are the same Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com