High-power long-wave infrared 8 micron-12 micron laser device based on polarization beam combination technology

A long-wave infrared and polarization beam combining technology, which is applied in the field of laser applications, can solve the problems of low conversion efficiency of a single optical parametric oscillator and difficulty in obtaining high output power of a single resonant cavity, and achieve the effect of improving the light-to-light conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

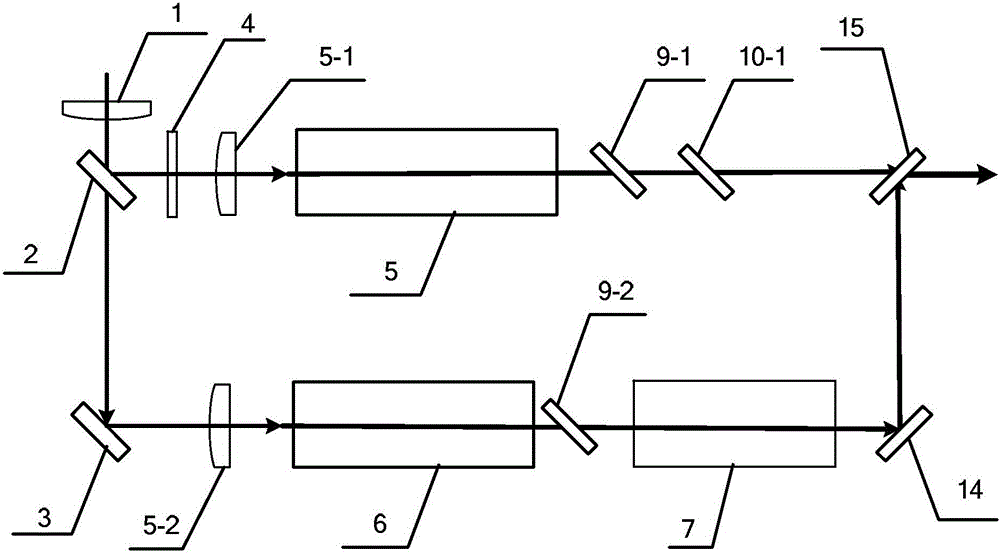

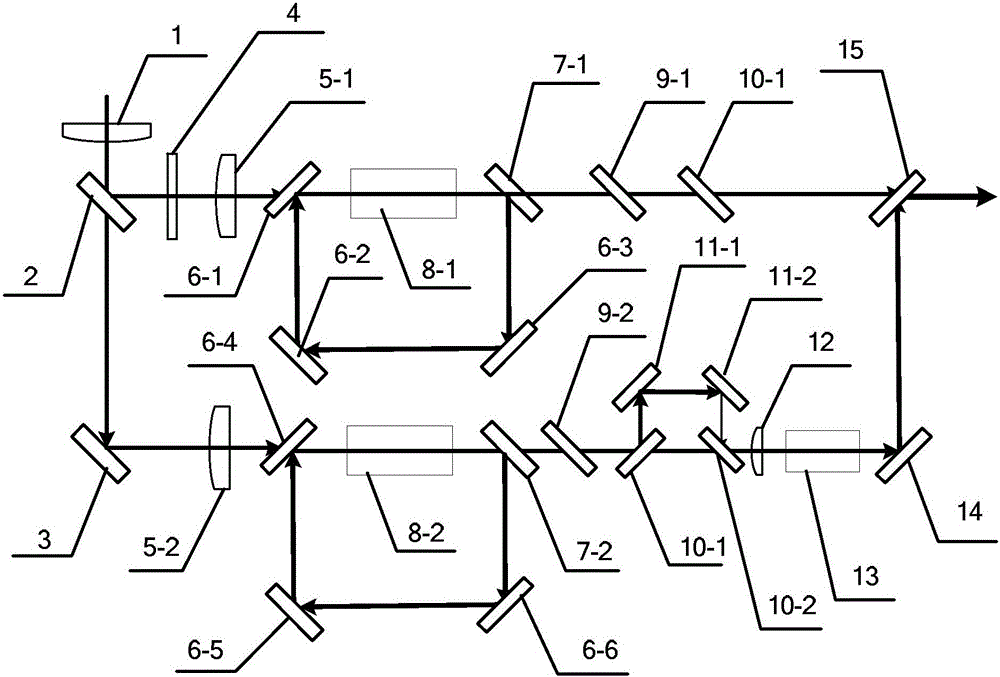

[0035] Specific implementation mode 1, refer to figure 1 and figure 2 Describe this embodiment in detail. The high-power long-wave infrared 8 μm to 12 μm laser based on polarization beam combining technology described in this embodiment includes No. 1 coupling system 5-1, No. 2 coupling system 5-2, and No. 3 coupling system 1. Beam splitter 2. No. 1 mirror 3. 1 / 2 wave plate 4. No. 1 ZnGeP 2 Optical parametric oscillator 5, No. 2 ZnGeP 2 Optical parametric oscillator 6, No. 1 plane mirror 9-1, No. 2 plane mirror 9-2, No. 3 plane mirror 10-1, ZnGeP2 optical parametric amplifier 7, No. 1 reflector 14 and polarizer 15;

[0036] A beam of 2.1 μm pulsed laser is vertically incident on the No. 3 coupling system 1, and after the beam conversion by the No. 3 coupling system 1, it enters the beam splitter 2 at an incident angle of 45°, and is divided into two beams by the beam splitter 2. It is horizontally polarized 2.1μm laser;

[0037] A beam of horizontally polarized 2.1 μm las...

specific Embodiment approach 2

[0042] Specific Embodiment 2. This specific embodiment is a further description of the high-power long-wave infrared 8 μm to 12 μm laser based on polarization beam combining technology described in specific embodiment 1. In this embodiment, No. 1 ZnGeP 2 The optical parametric oscillator 5 includes No. 4 plane mirror 6-1, No. 5 plane mirror 7-1, No. 2 reflector 6-2, No. 3 reflector 6-3 and No. 1 ZnGeP2 crystal 8-1;

[0043] After being converted by the No. 1 coupling system 5-1, it is incident on the No. 1 ZnGeP 2 The No. 4 plane mirror 6-1 of the optical parametric oscillator 5 has an incident angle of 45°. After being transmitted by the No. 4 plane mirror 6-1, it is incident on the No. 1 ZnGeP2 crystal 8-1, and passes through the No. 1 ZnGeP2 crystal 8-1 at 45 °. The incident angle enters the No. 5 plane mirror 7-1, and is reflected and transmitted by the No. 5 plane mirror 7-1;

[0044] After being reflected by No. 5 plane mirror 7-1, it is incident on No. 3 reflector 6-3 ...

specific Embodiment approach 3

[0047] Specific Embodiment 3. This specific embodiment is a further description of the high-power long-wave infrared 8 μm ~ 12 μm laser based on the polarization beam combining technology described in specific embodiment 1. In this embodiment, No. 2 ZnGeP 2 Optical parametric oscillator 6 comprises No. 6 plane mirror 6-4, No. 7 plane mirror 7-2, No. 4 reflector 6-5, No. 5 reflector 6-6 and No. 2 ZnGeP2 crystal 8-2;

[0048] The beam is transformed by the No. 2 coupling system 5-2 and then incident on the No. 2 ZnGeP 2 The No. 6 plane mirror 6-4 in the optical parametric oscillator 6 is incident to the No. 2 ZnGeP2 crystal 8-2 after being transmitted by the No. 6 plane mirror 6-4; No. plane mirror 7-2, reflected and transmitted through No. 7 plane mirror 7-2;

[0049] After being reflected by No. 7 plane mirror 7-2, it is incident on No. 5 reflector 6-6 at an incident angle of 45°; after being reflected by No. 5 reflector 6-6, it is incident on No. 4 reflector 6-5 at an incide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com