Method for preparing CuW/Cu/CuCrZr integrated contact through electron beam welding

A technology for electron beam welding and contacts, which is applied in the direction of electron beam welding equipment, welding equipment, welding/welding/cutting items, etc. It can solve the problems that affect the performance of self-supporting contacts, cannot realize automation, and have low mechanical properties at high temperatures , to achieve stable and reliable product quality, broaden product types, and high welding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The sintered CuW / Cu and CuCrZr are directly subjected to electron beam welding, the welding surface is Cu and CuCrZr, the welding joint is a flat butt joint, the joint gap is 0, and no welding filler material is filled. 45-degree angle weld seam, no need for heat treatment after welding, electron beam welding equipment: THDW-15 electron beam welding machine;

[0030] Welding parameters: ascending gradient: 10s,

[0031] Descent gradient: 15s,

[0032] Rotation speed: 4r / min

[0033] Welding time: 16s,

[0034] Filament: 20A,

[0035] Focus: 330mA,

[0036] Welding beam current: 122mA;

[0037] High voltage: 85Kv,

[0038] Bias voltage: 705V,

[0039] Scanning: X50mA, Y50mA,

[0040] Frequency: 500Hz.

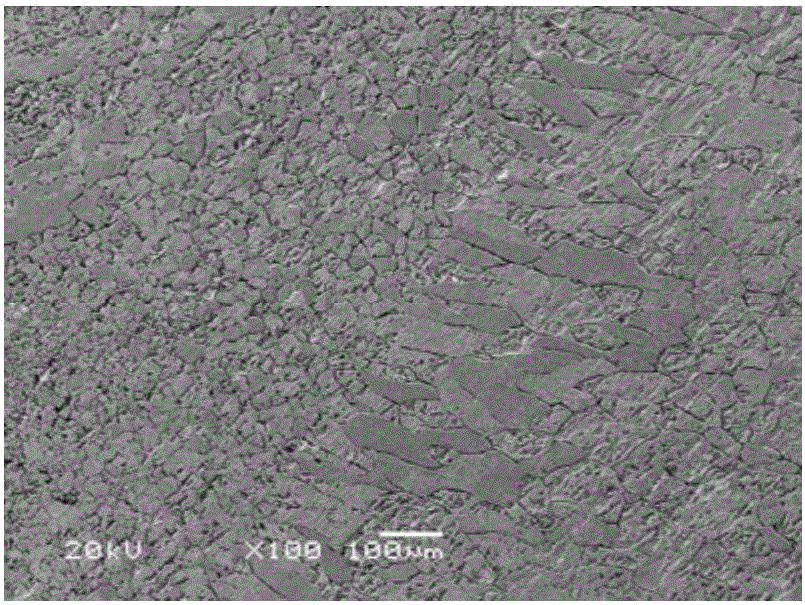

[0041] Observe the welded joint after welding, figure 1 It is a metal welding interface, the connection interface is flat, and there are relatively thick columnar crystals at the weld, but the grain growth is not strong, and has no obvious impact on the performa...

Embodiment 2

[0045] The sintered CuW / Cu and CuCrZr are directly subjected to electron beam welding, the welding surface is Cu and CuCrZr, the welding joint is a flat butt joint, the joint gap is 0, and no welding filler material is filled. 45-degree angle weld seam, no need for heat treatment after welding, electron beam welding equipment: THDW-15 electron beam welding machine;

[0046] Welding parameters: ascending gradient: 10s,

[0047] Descent gradient: 15s,

[0048] Rotation speed: 4r / min

[0049] Welding time: 16s,

[0050] Filament: 19.5A,

[0051] Focus: 340mA,

[0052] Welding beam current: 120mA;

[0053] High voltage: 85Kv,

[0054] Bias voltage: 715V,

[0055] Scanning: X50mA, Y50mA,

[0056] Frequency: 500Hz.

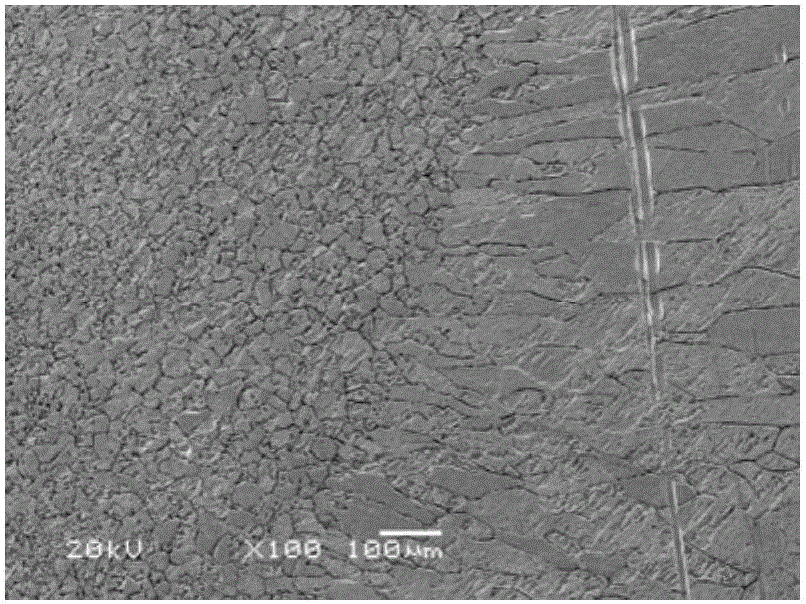

[0057] Observe the welded joint after welding, figure 2 It is a metal welding interface, the connection interface is flat, and there are relatively thick columnar crystals at the weld, but the grain growth is not strong, and has no obvious impact on the perfo...

Embodiment 3

[0061] The sintered CuW / Cu and CuCrZr are directly subjected to electron beam welding, the welding surface is Cu and CuCrZr, the welding joint is a flat butt joint, the joint gap is 0, and no welding filler material is filled. 45-degree angle weld seam, no need for heat treatment after welding, electron beam welding equipment: THDW-15 electron beam welding machine;

[0062] Welding parameters: ascending gradient: 10s,

[0063] Descent gradient: 15s,

[0064] Rotation speed: 4r / min

[0065] Welding time: 16s,

[0066] Filament: 19.0A,

[0067] Focus: 350mA,

[0068] Welding beam current: 125mA;

[0069] High voltage: 85Kv,

[0070] Bias voltage: 725V,

[0071] Scanning: X50mA, Y50mA,

[0072] Frequency: 500Hz.

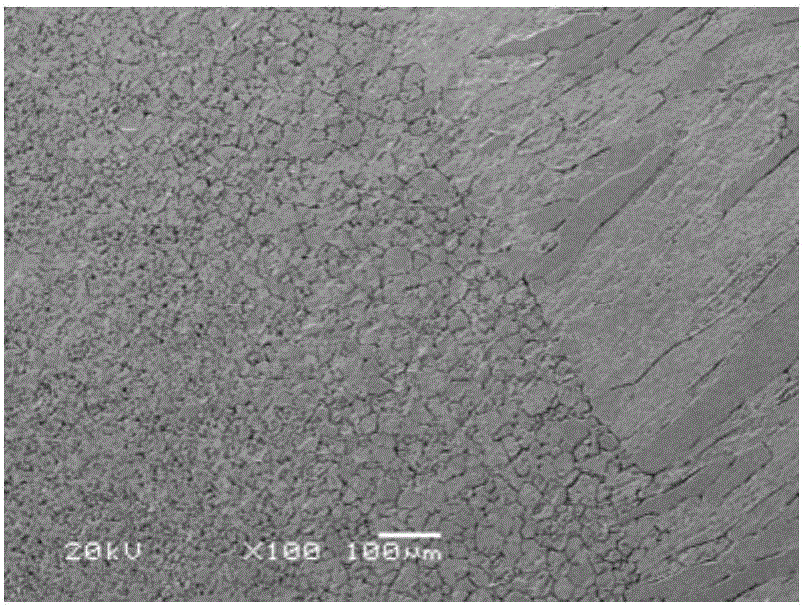

[0073] Observe the welded joint after welding, image 3 It is a metal welding interface, the connection interface is flat, and there are relatively thick columnar crystals at the weld, but the grain growth is not strong, and has no obvious impact on the performa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com