Synthesis method for 1,5-ketonic ester compound under catalyzing of inorganic base

A synthesis method and compound technology, applied in the preparation of organic compounds, chemical instruments and methods, organic chemistry, etc., can solve problems such as inability to achieve wide application and actual production, further application restrictions, harsh reaction conditions, etc., to achieve cost savings, The effect of reducing production costs and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

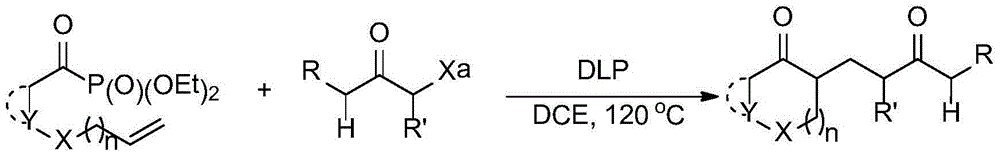

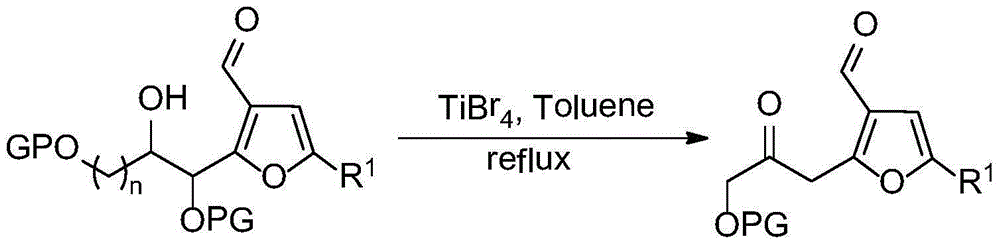

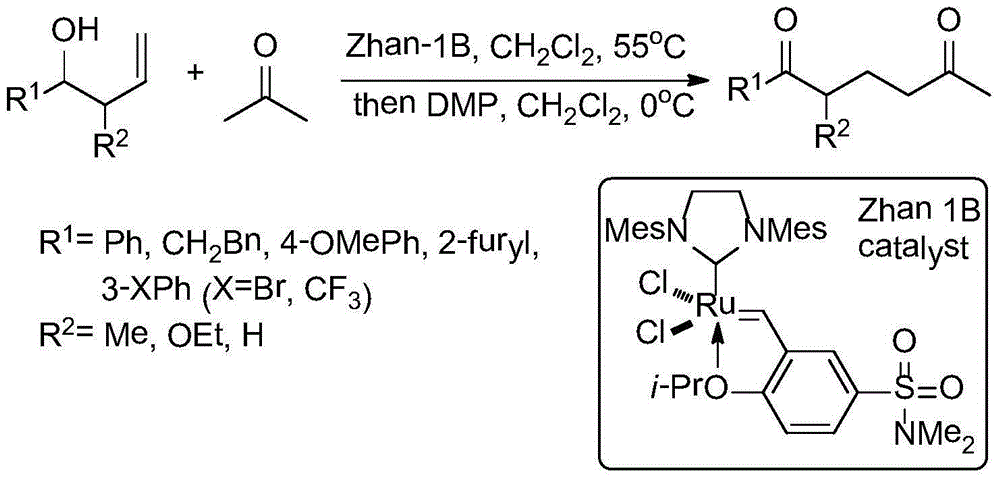

Method used

Image

Examples

Embodiment 1

[0045] The preparation of embodiment 1, ethyl 4-benzoyl butyrate (compound III-1)

[0046]

[0047] In the 20mL reaction tube, add compound dibenzoylmethane 112mg (0.5mmol), K 2 CO 3 7 mg (0.025 mmol), 109 μL (1 mmol) of ethyl acrylate and 2 mL of ethanol, stirred at 85 ° C for 2 hours under temperature control, cooled to room temperature (18 ~ 25 ° C), transferred to a 25 mL small flask, and placed on a rotary evaporator Spin off the solvent, and then use neutral alumina to pass through the column. The developer used is petroleum ether: ethyl acetate = 15:1 ~ 5:1, and the compound III-1108 mg is obtained, with a yield of 98%; a colorless oily liquid; 1 HNMR (600MHz, CDCl 3, 25℃, TMS): δ=7.97(d, J=7.6Hz, 2H), 7.56(t, J=7.4Hz, 1H), 7.46(t, J=7.6Hz, 2H), 4.14(q, J= 7.1Hz, 2H), 3.06(t, J=7.2Hz, 2H), 2.43(t, J=7.2Hz, 2H), 2.08(p, J=7.2Hz, 2H), 1.26ppm(t, J=7.1 Hz,3H); 13 CNMR (151MHz, CDCl 3, 25℃, TMS) δ=199.45(s), 173.26(s), 136.96(s), 133.06(s), 128.62(s), 128.06(s), 60...

Embodiment 2

[0048] The preparation of embodiment 2,4-p-methoxybenzoyl ethyl butyrate (compound III-2)

[0049]

[0050] Add compound 1,3-bis(4-methoxyphenyl)1,3-propanedione 142mg (0.5mmol), K 2 CO 3 7 mg (0.025 mmol), 109 μL (1 mmol) of ethyl acrylate and 2 mL of ethanol, stirred at 85 ° C for 2 hours under temperature control, cooled to room temperature (18 ~ 25 ° C), transferred to a 25 mL small flask, and placed on a rotary evaporator The solvent was spun off, and then passed through the column with neutral alumina, and the developer used was petroleum ether: ethyl acetate = 25:1-8:1 to obtain 175 mg of compound III-2, with a yield of 70%; the melting point of the white solid was 56-59°C; 1 HNMR (600MHz, CDCl 3, 25℃, TMS) δ=7.95(d, J=8.6Hz, 2H), 6.93(d, J=8.6Hz, 2H), 4.14(q, J=7.1Hz, 2H), 3.86(s, 3H), 2.99(t, J=7.2Hz, 2H), 2.42(t, J=7.2Hz, 2H), 2.06(p, J=7.2Hz, 2H), 1.25ppm(t, J=7.1Hz, 3H); 13 CNMR (151MHz, CDCl 3, 25℃, TMS) δ=197.99(s), 173.27(s), 163.47(s), 130.27(s), 130.0...

Embodiment 3

[0051] The preparation of embodiment 3, ethyl 4-pyridineformyl butyrate (compound III-3)

[0052]

[0053] Add compound 1,3-bis(2-pyridyl)1,3-propanedione 113mg (0.5mmol), K 2 CO 3 7 mg (0.025 mmol), 109 μL (1 mmol) of ethyl acrylate and 2 mL of ethanol, stirred at 85 ° C for 2 hours under temperature control, cooled to room temperature (18 ~ 25 ° C), transferred to a 25 mL small flask, and placed on a rotary evaporator The solvent was spun off, and then neutral alumina was used to pass through the column. The developer used was petroleum ether: ethyl acetate = 10:1 ~ 3:1 to obtain 166 mg of compound III-3 with a yield of 75%; 1 HNMR (600MHz, CDCl 3, 25℃, TMS)) δ=8.67(d, J=4.7Hz, 1H), 8.04(d, J=7.8Hz, 1H), 7.84(t, J=7.7Hz, 1H), 7.50–7.44(m, 1H), 4.14(q, J=7.1Hz, 2H), 3.29(t, J=7.3Hz, 2H), 2.44(t, J=7.4Hz, 2H), 2.08(p, J=7.3Hz, 2H) ,1.25ppm(t,J=7.1Hz,3H); 13 CNMR (151MHz, CDCl 3, 25℃, TMS) δ=201.08(s), 173.20(s), 153.33(s), 148.91(s), 136.83(s), 127.06(s), 121.69(s), 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com