Preparation method of disinfecting material namely methyl guanidine chitosan hydrochloride

A technology of methylguanidine salt and polyhexamethylene hydrochloric acid, applied in the field of chemical biology of renewable resources, to achieve significant sterilization, good sterilization and antibacterial effects, and excellent antivirus effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

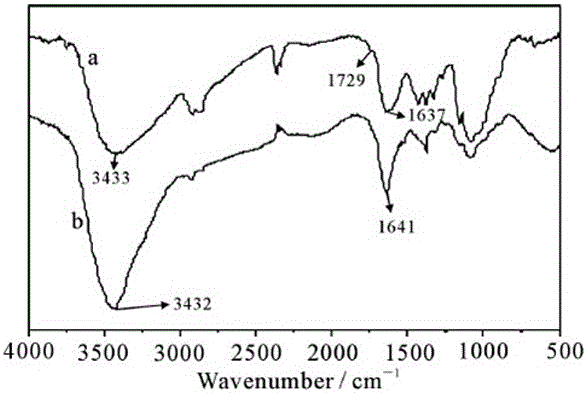

Image

Examples

Embodiment 1

[0027] The preparation of embodiment 1 polyhexamethylene guanidine hydrochloride (PHGC)

[0028] Preparation of polyhexamethylene guanidine hydrochloride: Weigh 116.21 grams of 1,6-hexamethylenediamine and 95.53 grams of guanidine hydrochloride and melt and react at 120°C for half an hour. After NH3 is released, heat up to 180°C to continue the reaction for 3 hours, and then rapidly cool To room temperature, obtain white or milky white, no peculiar smell solid namely polyhexamethylene guanidine hydrochloride (PHGC).

Embodiment 2

[0029] The preparation of embodiment 2 salt polyhexamethylene guanidinium hydrochloride (PHGH)

[0030]The preparation of polyhexamethylene guanidine hydrochloride-glycidyl methacrylate polymer (PHGH): take by weighing 5.8 grams of polyhexamethylene guanidine hydrochloride and be dissolved in 50mL volume ratio of ethanol, acetone and In the mixed solution of water, weigh 4.3 grams of glycidyl methacrylate and dissolve it in 4 mL of acetone, mix the above two, stir and react at 40 ° C for 6 hours under the protection of nitrogen, and then rotary evaporate to obtain the product polyhexamethylene A polymer of guanidine hydrochloride-glycidyl methacrylate, namely polyhexamethylene guanidinium hydrochloride (PHGH).

Embodiment 3

[0031] The preparation of embodiment 3 methylguanidine hydrochloride chitosan

[0032] The preparation of methylguanidine hydrochloride chitosan: the salt polyhexamethylene guanidine hydrochloride (PHGH) of 0.69 gram is dissolved in the distilled water of 13.2mL equal substance quantity and acetic acid mixed solution, add 2.04 gram molecular weight and be 3-30 10,000 chitosan and stirred, after passing through N2 for 10 minutes, add 0.015 g of ammonium cerium nitrate, adjust the pH to 5-6 with 0.1 mg / L dilute nitric acid, stir and react in N2 atmosphere for 3 hours, and settle with acetone to obtain crude grafted product. Finally, it was extracted with ethanol for 8 hours, vacuum-dried, and ground to obtain 3.66 g of pure grafted product, ie methylguanidine hydrochloride chitosan.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com