Limonite hydrometallurgy process

A technology of hydrometallurgy and limonite, which is applied in the field of metallurgy, can solve the problems that iron cannot be economically and effectively developed and utilized, the leaching rate of nickel and cobalt is low, and it can only be treated as waste solid, so as to achieve efficient development and utilization and consumption of sulfuric acid The effect of low quantity and avoiding expensive equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

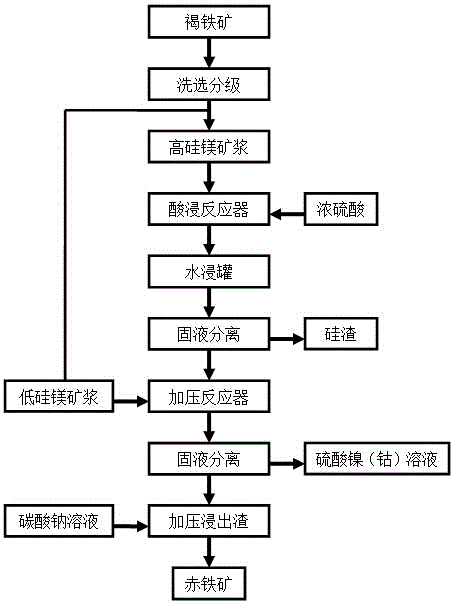

Image

Examples

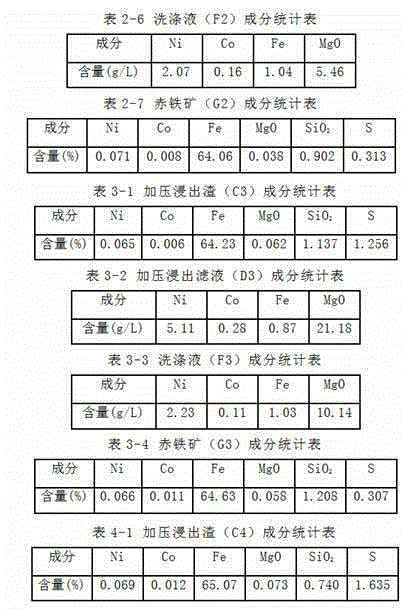

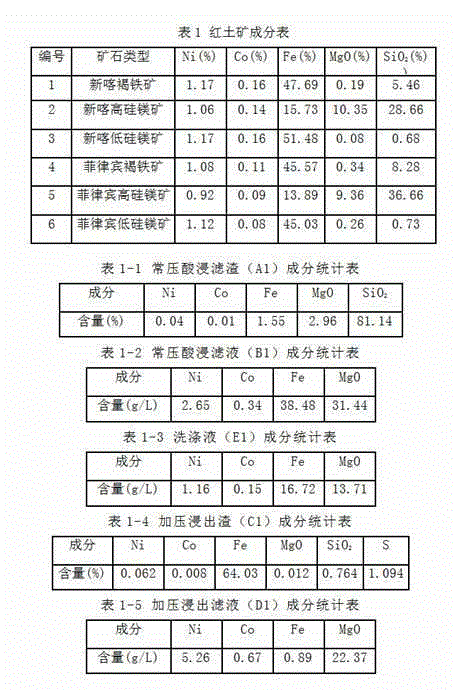

Embodiment 1

[0029] 1. Washing and classifying limonite ore, separating coarser minerals such as gravel and sandstone in limonite from the raw ore to obtain high-silicon-magnesium ore and low-silicon-magnesium ore;

[0030] 2. Set +80 purpose 2 # 500kg of high-silicon magnesium ore plus 500kg of water is prepared to obtain 50wt% ore slurry, which is for use;

[0031] 3. Simultaneously add 450kg of 98% concentrated sulfuric acid heated to 150°C to the double-screw pusher reactor and step 2 to prepare 50wt% ore pulp heated to 60°C. After mixing, it will be pushed out by the double-screw pusher reactor for the entire reaction time After 10 minutes, the material released by the double-screw pusher reactor is a crisp honeycomb solid paste, ready for use;

[0032] 4. Simply crush the crisp honeycomb solid paste obtained in step 3, pour it into a water immersion tank after crushing, add water equal to the weight of the crisp honeycomb solid paste, carry out the water dissolving step, and stir fo...

Embodiment 2

[0045] 1. Take the limonite ore for washing and classification, separate coarser minerals such as gravel and sandstone in the limonite from the raw ore, and pass through an 80-mesh sieve to obtain +80-mesh ore and -80-mesh ore;

[0046] 2. Put +80 mesh 5 # Add water to high silicon magnesium ore to prepare 50wt% ore slurry, stand-by;

[0047] 3. Simultaneously add 450kg of 98% concentrated sulfuric acid heated to 150°C to the double-screw pusher reactor and step 2 to prepare 50wt% ore pulp heated to 60°C. After mixing, it will be pushed out by the double-screw pusher reactor for the entire reaction time After 10 minutes, the material released by the double-screw pusher reactor is a crisp honeycomb solid paste, ready for use;

[0048] 4. Simply crush the crisp honeycomb solid paste obtained in step 3, pour it into a water immersion tank after crushing, add water equal in weight to the crisp honeycomb solid paste, carry out the water-dissolving step, and stir for 30 minutes;

...

Embodiment 3

[0060] 1. Take the limonite ore for washing and classification, separate coarser minerals such as gravel and sandstone in the limonite from the raw ore, and pass through an 80-mesh sieve to obtain +80-mesh ore and -80-mesh ore;

[0061] 2. Set +80 purpose 2 # 500kg of high-silicon magnesium ore plus 500kg of water is prepared to obtain 50wt% ore slurry, which is for use;

[0062] 3. Simultaneously add 450kg of 98% concentrated sulfuric acid heated to 150°C to the double-screw pusher reactor and step 2 to prepare 50wt% ore pulp heated to 60°C. After mixing, it will be pushed out by the double-screw pusher reactor for the entire reaction time After 10 minutes, the material released by the double-screw pusher reactor is a crisp honeycomb solid paste, ready for use;

[0063] 4. Simply crush the crisp honeycomb solid paste obtained in step 3, pour it into a water immersion tank after crushing, add water equal to the weight of the crisp honeycomb solid paste, carry out the water di...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap