Application of renewable plant fiber, cigarette paper with hole forming function through thermal cracking, and preparation method and application of cigarette paper

A plant fiber and cigarette paper technology, which is applied in the direction of non-woody plant/crop pulp, fiber raw material processing, non-fiber pulp addition, etc., can solve the problems of high cost, large negative impact of cigarettes, and unfavorable widespread promotion and use, and achieve improvement The effect of burning degree, reducing release amount, increasing pore volume and micropore number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

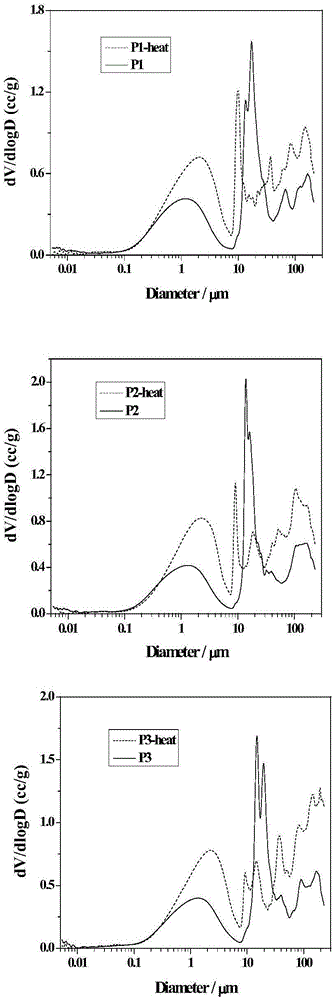

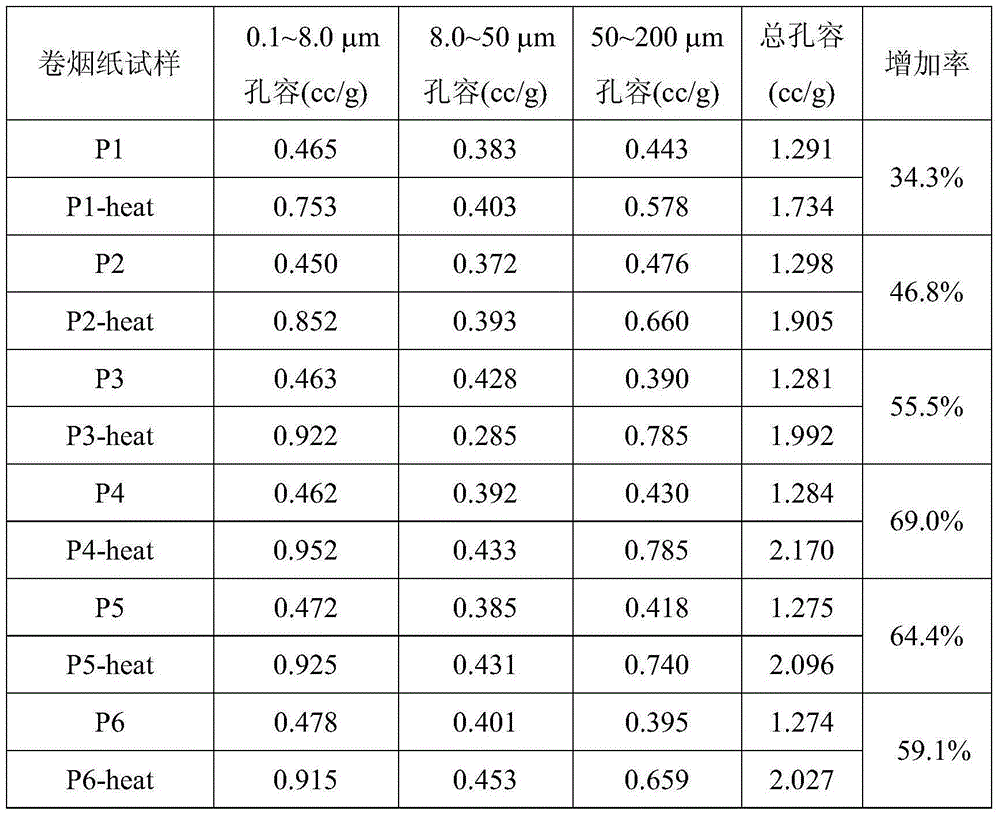

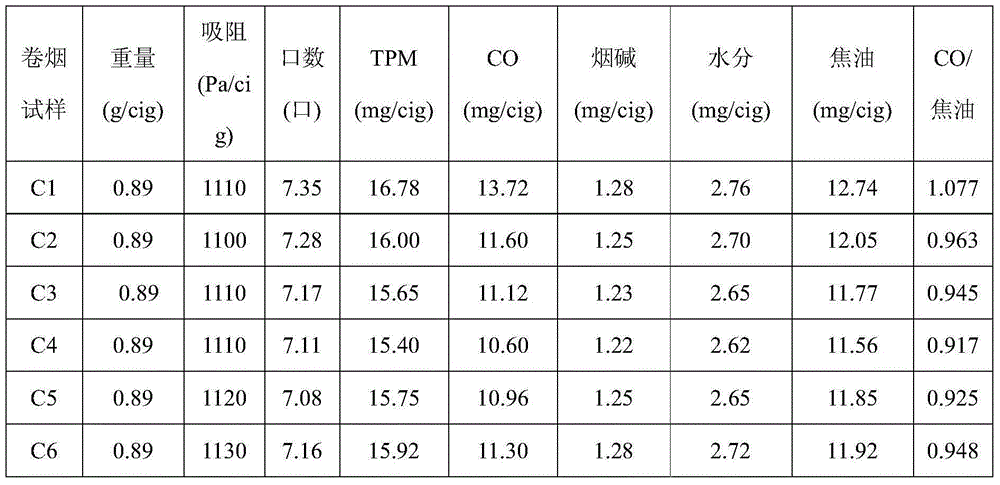

[0035] Get 150 kilograms of softwood pulp, 200 kilograms of hardwood pulp, 50 kilograms of soybean fiber (400-600 mesh), 50 kilograms of straw fiber (400-600 mesh), add 250 kilograms of calcium carbonate for beating and papermaking, and the preparation mass percentage is 10% Potassium citrate and 6% sodium citrate mixed additive solution, the prepared additive solution is evenly added to the cigarette paper through the metering rod film transfer sizing machine in the sizing section of cigarette paper production, and produced according to the conventional papermaking method Cigarette paper, the parameters of cigarette paper controlled on the equipment are: quantitative 29gm -2 , the air permeability is 60CORESTA, the amount of additive added in the cigarette paper is 1.00gm -2 (No. P2). The paper diffusivity was tested by Sodim's automatic paper diffusivity meter. The test process for the change of the diffusivity of the test paper before and after heating is as follows: mark...

Embodiment 2

[0037] Get 160 kilograms of coniferous wood pulp, 210 kilograms of hardwood pulp, 100 kilograms of corn fiber (0.5~1.0mm long), 60 kilograms of soybean fiber (0.5~1.0mm long), add 250 kilograms of calcium carbonate for pulping and papermaking, and the preparation mass percentage is 10% potassium citrate and 6% sodium citrate mixed additive solution, the prepared additive solution is evenly added to the cigarette paper in the sizing section of cigarette paper production through a metering rod film transfer sizing machine, and the paper is made according to the conventional method Method to produce cigarette paper, the parameters of cigarette paper are controlled on the equipment: quantitative 29gm -2 , the air permeability is 60CORESTA, the amount of additive added in the cigarette paper is 1.00gm -2 (No. P3). The paper diffusivity was tested by Sodim's automatic paper diffusivity meter. The test process for the change of the diffusivity of the test paper before and after hea...

Embodiment 3

[0039] Get 200 kilograms of coniferous wood pulp, 200 kilograms of hardwood pulp, 50 kilograms of corn fiber (0.5~1.0mm long), 50 kilograms of straw fiber (0.5~1.0mm long), add 300 kilograms of calcium carbonate for beating and papermaking, and the prepared mass percentage is 10% potassium citrate and 6% sodium citrate mixed additive solution, the prepared additive solution is evenly added to the cigarette paper in the sizing section of cigarette paper production through a metering rod film transfer sizing machine, and the paper is made according to the conventional method Method to produce cigarette paper, the parameters of cigarette paper are controlled on the equipment: quantitative 29gm -2 , the air permeability is 60CORESTA, the amount of additive added in the cigarette paper is 1.00gm -2 (No. P4). The paper diffusivity was tested by Sodim's automatic paper diffusivity meter. The test process for the change of the diffusivity of the test paper before and after heating i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com