A kind of samarium cobalt permanent magnet material ball mill wet powder rapid drying device and method

A permanent magnet material, rapid drying technology, applied in the direction of drying solid materials, drying solid materials without heating, drying, etc., can solve the problems of unsuitability for industrialized mass production, low efficiency, long time consumption, etc., and achieves strong practicability , High production efficiency and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

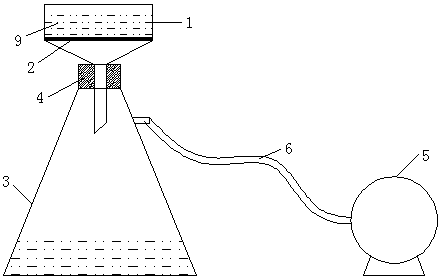

[0030] Referring to the accompanying drawings, the rapid drying device for ball milled wet powder of samarium cobalt permanent magnet material in this embodiment is composed of a suction filtration part and a drying part, and the suction filtration part includes:

[0031] A ceramic Buchner funnel 1, the cylinder bottom of the ceramic Buchner funnel 1 is covered with a layer of qualitative filter paper 2, and the ceramic Buchner funnel 1 is used to hold the wet powder 9 of the ball mill of samarium cobalt permanent magnet material;

[0032] A glass filtration flask 3, which is sealed and connected to the ceramic Buchner funnel 1 through a rubber ring 4 (or a rubber plug with a hole in the middle);

[0033] A rotary vane vacuum pump 5, the exhaust port of the rotary vane vacuum pump 5 is connected with the upper mouth of the glass filter bottle 3 through a rubber tube 6;

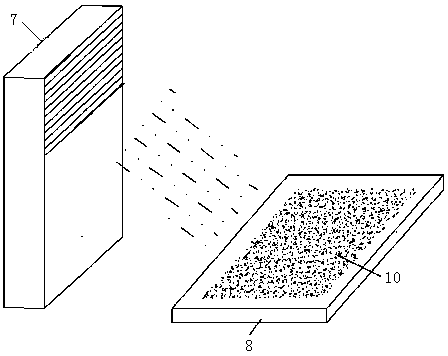

[0034] The drying part is made up of a cabinet air conditioner 7 and a flat bottom stainless steel dish 8 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com