Heat pump drying device with humidity and temperature adjusting function

A heat pump drying and humid heat technology, applied in drying, heat pumps, dryers, etc., can solve problems such as difficult to achieve temperature and humidity control process requirements, insufficient energy saving and environmental protection, and waste of heat, so as to reduce energy consumption and pressure ratio , Improve the effect of heating energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

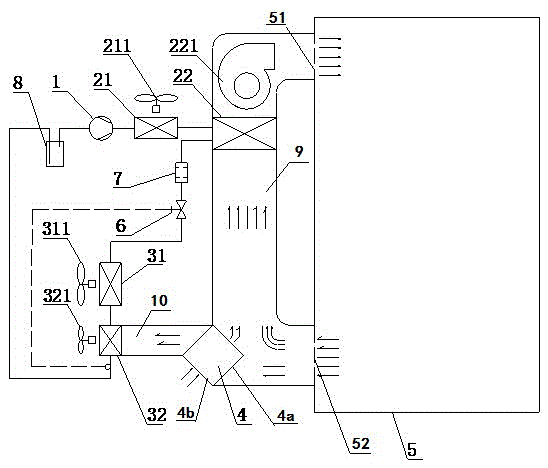

[0013] refer to figure 1 The shown heat pump drying device that can realize humidity and heat regulation includes a drying room 5, a return air channel 9 connected to the air supply port 51 and the return air port 52 of the drying room 5, and a circulating fan 221 arranged in the return air channel 9 , the exhaust duct 10 communicated with the air return duct 9, the exhaust fan 321 arranged at the mouth of the exhaust duct 10, the air heat recovery device 4 arranged at the junction of the return air duct 9 and the exhaust duct 10, and the heat pump unit.

[0014] The heat pump unit includes a compressor 1, a temperature-regulating condenser 21, a main condenser 22, a dry filter 7, an expansion valve 6, an outdoor evaporator 31, a heat recovery evaporator 32, and a gas-liquid separator 8 connected in series through pipelines; The main condenser 22 is arranged in the return air passage 9 , and the heat recovery evaporator 32 is arranged at the passage opening of the exhaust air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com