Method for determination of content of lead in chrome ore

A determination method and technology of lead content, which is applied in the preparation of test samples, fluorescence/phosphorescence, material excitation analysis, etc., can solve the problems that are not suitable for the determination of lead in chrome ore, and achieve stable fusion sample results, ensure stability, well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

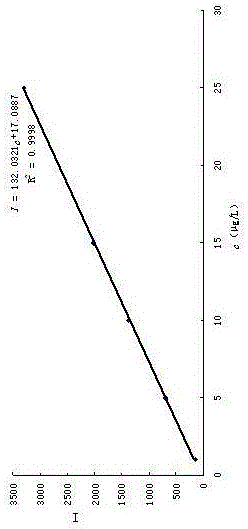

Image

Examples

Embodiment 1

[0026] Embodiment 1, a kind of assay method of lead content in chrome ore, its step is,

[0027] (1) Preparation of sample solution

[0028] Weigh 0.2g of lead-containing chrome ore sample, place it in a corundum crucible pre-added with 0.8g of sodium peroxide, cover the sample with 0.8g of sodium peroxide, and put the corundum crucible at 600°C for melting 15min, take out, cool to room temperature;

[0029] Put the cooled corundum crucible containing the melt into a beaker, add 45mL of hot water at a temperature of 60°C to soak the melt, pour the soaked melt into the beaker, and wash the inside and outside of the corundum crucible with hydrochloric acid solution and water. Rinse the residual melt into the beaker, then add 8-12mL hydrochloric acid solution into the beaker, dissolve the precipitate and acidify to obtain the melt solution, cool to normal temperature, transfer the melt solution to a 100mL volumetric flask, dilute with water to the mark, mix;

[0030] Pipette 3...

Embodiment 2

[0037] Embodiment 2, a kind of assay method of lead content in chrome ore, its step is,

[0038] (1) Preparation of sample solution

[0039] Weigh 0.7g of lead-containing chromium ore sample, place it in a corundum crucible pre-added with 1.2g of sodium peroxide, cover the sample with 1.2g of sodium peroxide, and put the corundum crucible at a temperature of 700°C to melt 25min, take out, cool to room temperature;

[0040] Put the cooled corundum crucible containing the melt into a beaker, add 45mL of hot water at 100°C to soak the melt, pour the soaked melt into the beaker, and wash the inside and outside of the corundum crucible with hydrochloric acid solution and water. Rinse the residual melt into the beaker, then add 12mL hydrochloric acid solution into the beaker, dissolve the precipitate and acidify to obtain the melt solution, cool to room temperature, transfer the melt solution to a 100mL volumetric flask, dilute with water to the mark, and mix well ;

[0041] Pipe...

Embodiment 3

[0048] Embodiment 3, the assay method of lead content in the chrome ore described in embodiment 1: in the on-machine test described in step (4), fluorescence intensity test is 230mV at negative high voltage, lamp current is 55mA, atomizer height It is carried out under the conditions of 6mm, auxiliary gas flow rate of 380mL / min, and shielding gas flow rate of 700mL / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com