Electrode piece processing technique for lithium ion battery

A lithium-ion battery and processing technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as easy piercing of the diaphragm, battery burning, explosion, etc., to avoid battery short-circuit, reduce short-circuit rate, and improve safety performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

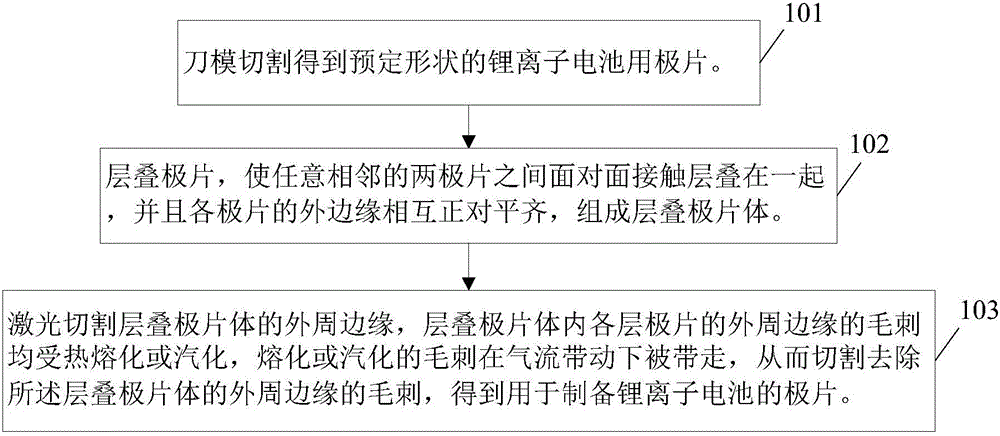

Method used

Image

Examples

Embodiment 1

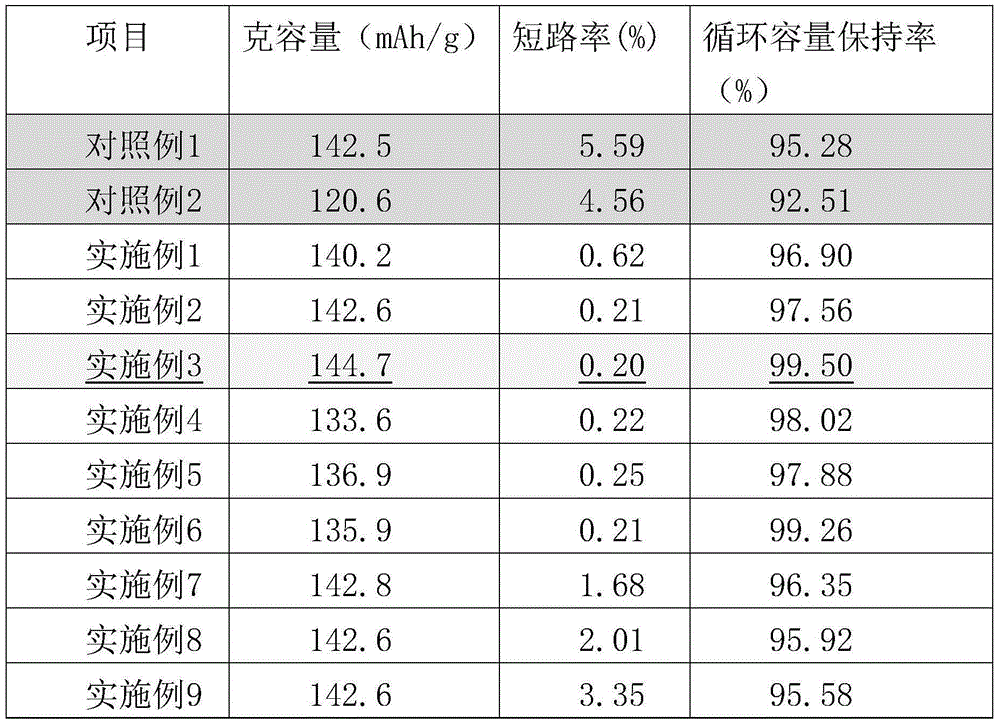

[0057] The difference between the present embodiment 1 and the comparative example 2 only lies in:

[0058] After cutting the obtained pole pieces with a conventional knife die, the pole pieces are stacked to form a laminated pole piece body, and the pole pieces are subjected to laser deburring treatment as described in the specific embodiment of the present invention. Wherein the laser intensity is the same as that of Comparative Example 2, the shape of the cutting edge formed by the laser is consistent with the outer peripheral edge of the laminated pole piece body, and the distance between the cutting edge formed by the laser and the outer peripheral edge of the laminated pole piece body is 1 mm.

Embodiment 2

[0060] The difference between this embodiment and embodiment 1 is only:

[0061] The distance between the shape of the cutting edge formed by the laser and the outer peripheral edge of the laminated pole piece body is 2 mm.

Embodiment 3

[0063] The difference between this embodiment and embodiment 2 only lies in:

[0064] During laser cutting, there is flow gas passing around the laminated pole piece body (at least the orthographic projection area of the diffuse pole piece, that is, the top surface and the ground and the gap between the top surface and the ground that enters the laminated pole piece). Flowing gas is normal temperature gas.

[0065] The volume ratio of the flowing gas is as follows: argon: nitrogen: methane = 3:6:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| beam width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com