mip‑spme extraction fiber and extraction platform and application

A fiber extraction and extraction technology, which is applied to chemical instruments and methods, other chemical processes, instruments, etc., can solve the problems of quartz fibers that are easy to break, complicated preparation process, and short service life, so as to overcome fragility and make the preparation process simple and fast , the effect of controllable film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

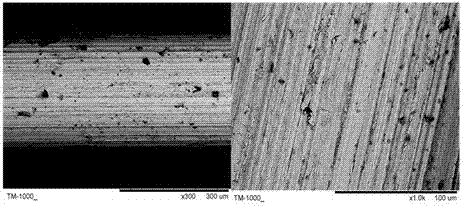

[0026] The MIP-SPME extraction fiber includes a base material and a tebuconazole-molecularly imprinted polymer coating on its surface, the base material is a metal material, and the tebuconazole-molecularly imprinted polymer coating is electropolymerized Fixed on the surface of the base material.

[0027] This study tried to use metal materials as the base material of the SPME extraction head to overcome the shortcomings of traditional quartz fibers such as easy breakage and short service life. At the same time, the coating material was immobilized on the metal surface by electropolymerization, which requires the metal to have good properties. For conductivity, Pt is a better choice among traditional electrode materials, and it is preferable to use Pt wire as the base material of SPME for the experimental study of electropolymerization.

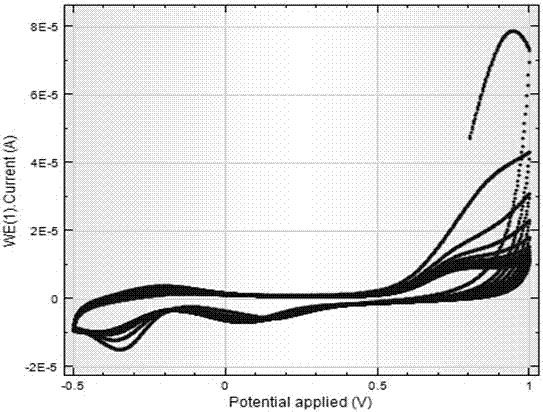

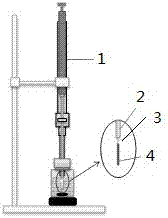

[0028] The MIP-SPME extraction fiber is prepared by in-situ electropolymerization-potentiostatic method. The specific operation is: based on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com